Method and apparatus for measuring material piezoelectric coefficient by using scanning near-field microwave microscopy

A technology for scanning near-field and piezoelectric coefficients, which is used in measuring devices, measuring electrical variables, instruments, etc., and can solve the problems of unable to obtain piezoelectric coefficients, unable to obtain deformation data, and unable to directly measure piezoelectric deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

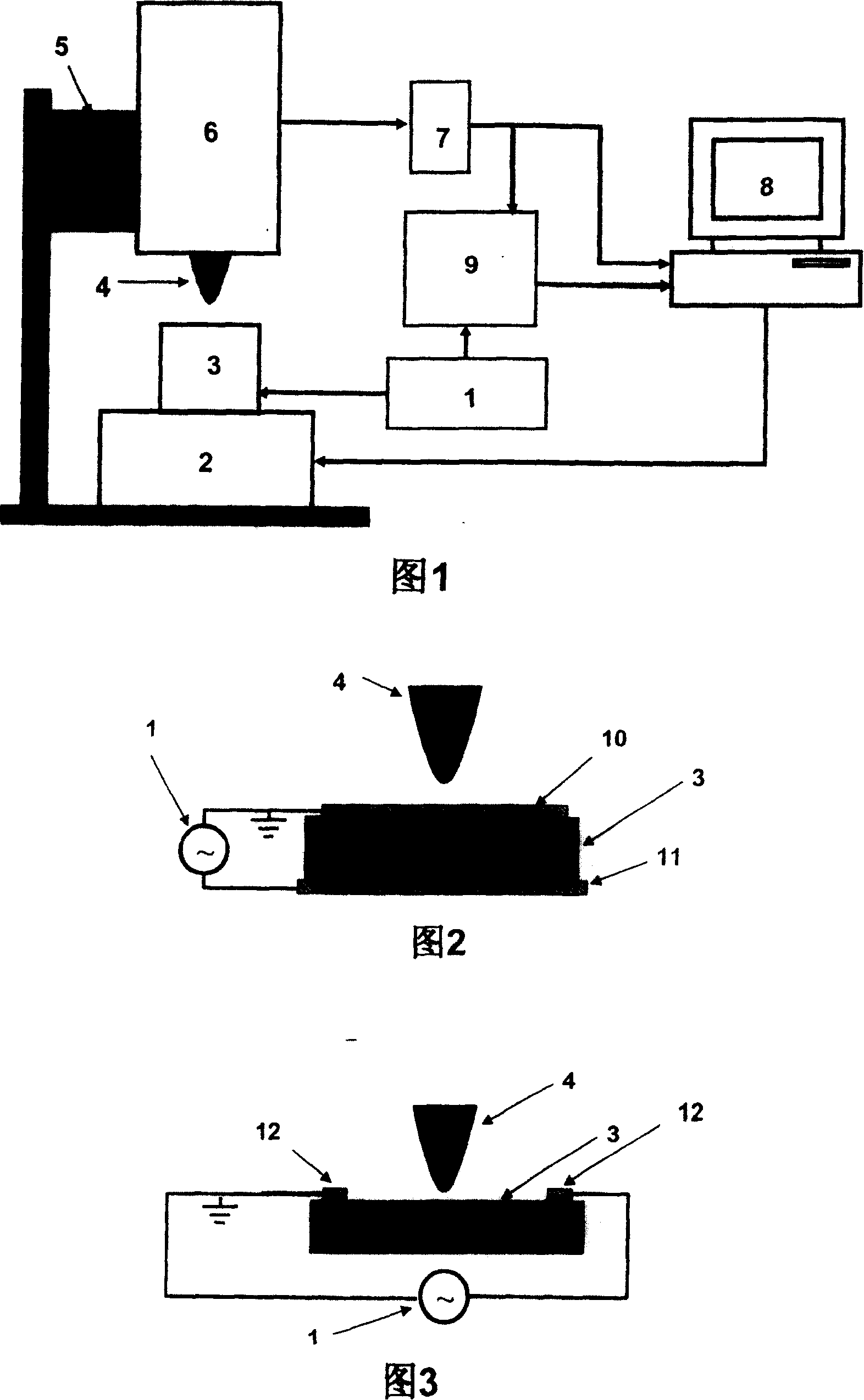

[0033] Embodiment 1: Measuring the longitudinal piezoelectric coefficient of PZT piezoelectric ceramics

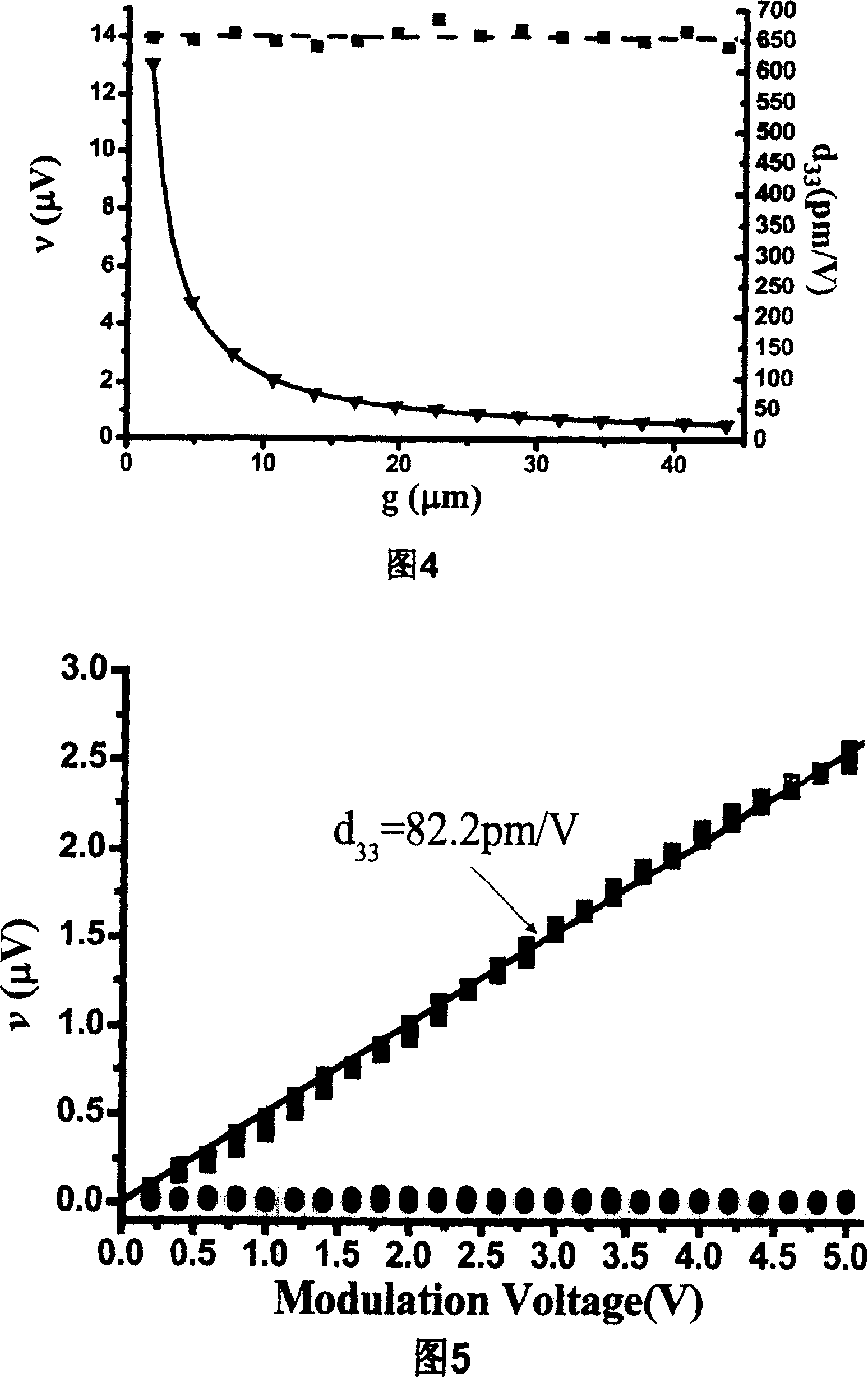

[0034] (1) As shown in Figure 2, in a 5mm×5mm×4mm lead zirconate titanate (Pb(ZrTi)O 3 , referred to as: PZT) electrodes are set on the upper and lower surfaces of the piezoelectric ceramic block sample, which is fixed on the scanning stage of a near-field microwave microscope (EMP2001, Ariel Technology, Inc., USA), and connected as shown in Figure 1 and Figure 2. Equipment and power supply: connect the sinusoidal alternating voltage generated by the signal generator (SG1643, Jiangsu Hongzerruite Electronic Equipment Co., Ltd.) to the two electrodes of the piezoelectric ceramic sample, and connect the signal output by the near-field microwave microscope to the lock Phase amplifier (SR 830, U.S. Stanford Research Systems, Inc.) input terminal, the modulated signal that the signal generator produces separates one and is connected with the lock-in amplifier reference signal i...

Embodiment 2

[0040] Embodiment 2: measure the longitudinal piezoelectric coefficient of PZT film

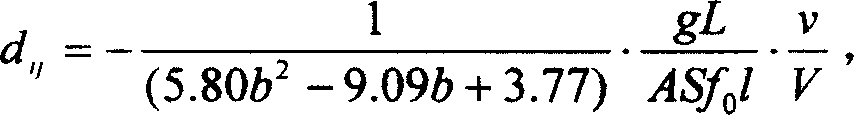

[0041] The sample is a PZT piezoelectric film with a thickness of 1 μm. Electrodes are fabricated on the sample as shown in FIG. 2 . The near-field microwave microscope, signal generator, and lock-in amplifier selected are the same as in Example 1, and the circuit connection method is also the same. In the near-field microwave microscope, the distance between the probe and the electrode on the sample is selected as 1.24 microns, and remains unchanged. The calibration constant A of the scanning near-field microwave microscope, the frequency response coefficient S of the microwave system of the scanning near-field microwave microscope, and the resonant frequency f of the microwave resonant cavity when there is no sample 0 All the same as in Example 1. Figure 5 shows the change of the output of the lock-in amplifier with the modulation voltage (square symbols, the modulation frequency is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com