Light-emitting assembly packaing structure, Backlight module applying it and liquid crystal display device thereof

A technology of light-emitting components and packaging structures, applied in instruments, optics, nonlinear optics, etc., can solve problems such as uneven light sources, and achieve the effect of increasing light incident efficiency and reducing light mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

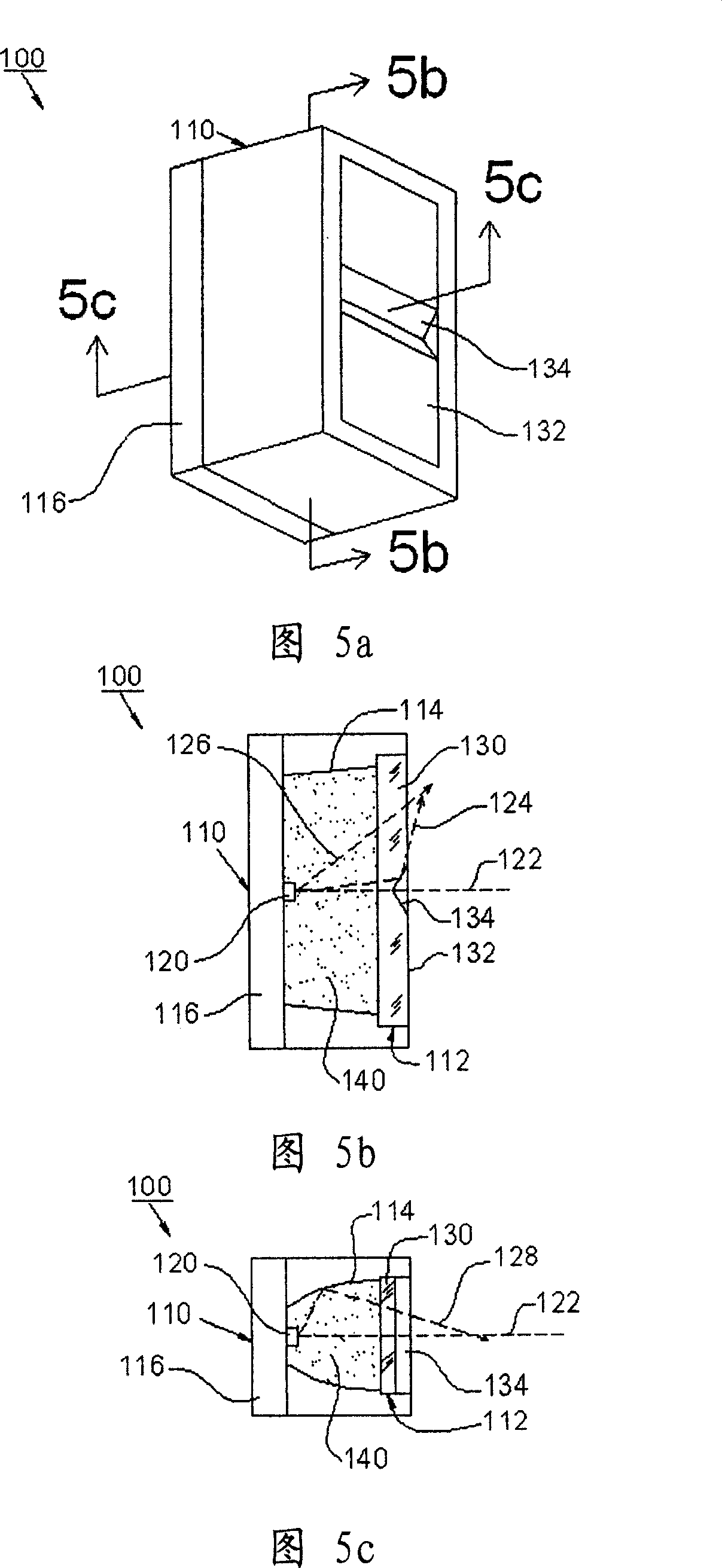

[0074] Referring to FIG. 5 a , FIG. 5 b and FIG. 5 c , they show a light emitting device packaging structure 100 according to a first embodiment of the present invention. The light emitting component packaging structure 100 includes a frame body 110 , at least one light emitting component 120 and a lens 130 . The frame 110 has an opening 112 , an inner side 114 and a bottom 116 , wherein the inner side 114 can be composed of at least one plane and / or at least one arc. The light emitting component 120 can be a light emitting diode (LED) or other light sources with high light intensity and directivity. The light emitting component 120 is located in the frame body 110 , for example, the light emitting component 120 is fixed on the bottom 116 of the frame body 110 for emitting light. The frame body 110 has at least one reflective surface (not shown), which can be located on the bottom 116 and / or the inner side 114 of the frame body 110 for reflecting the light emitted by the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com