Online monitoring device for micro-optics lens in semiconductor laser to be precisely adjusted and using method of online monitoring device

A monitoring device and laser technology, applied in the application field of laser technology, can solve the problems such as the inability to meet the precise control requirements of the divergence angle and directivity of semiconductor lasers, the inability to accurately monitor the mutual influence of the displacement axis and the rotation axis, etc., and achieve outstanding substantive characteristics. , The monitoring criterion is precise and reliable, and the effect of low divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

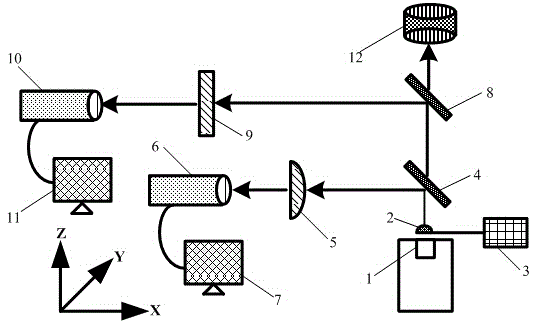

[0023] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

[0024] First, set the coordinate system: X direction is the slow axis direction of the semiconductor laser, Y direction is the fast axis direction of the semiconductor laser, and Z direction is the direction of the semiconductor laser beam. Fix the micro-optical lens to the six-axis adjustment frame and drive it with a DC power supply. The semiconductor laser emits light and adjusts the six-axis adjustment frame to perform preliminary alignment of the semiconductor laser.

[0025] A near-field beam splitter with a transmittance and reflectance ratio of 1:1 is placed on the preliminarily collimated semiconductor laser beam transmission path, and the angle between the near-field beam splitter and the incident laser beam is constrained within the range of (45±1)°.

[0026] Place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com