Magnetoresistive sensor with decoupled hard bias multilayers

A magnetoresistive sensor and bias layer technology, applied in the field of magnetic bias, can solve problems such as reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

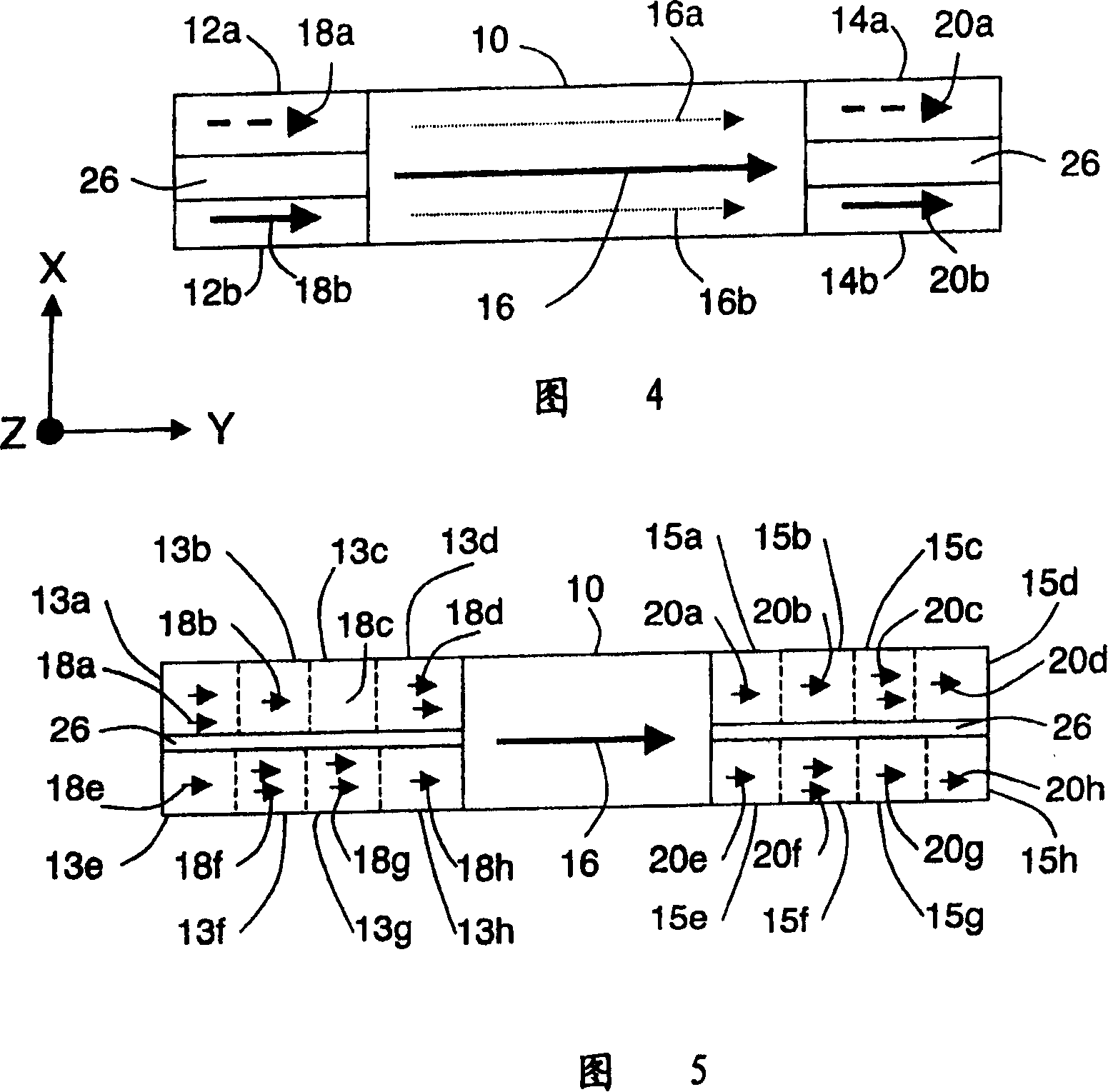

[0025] FIG. 4 shows a portion of a magnetic sensor according to an embodiment of the invention having a multilayer magnetic bias assembly that independently provides multiple magnetic biases to the free layer 10 . Bias layers 12a and 12b are separated by decoupling layer 26 . Likewise, bias layers 14a and 14b are separated by decoupling layer 26 . Decoupling layer 26 serves to substantially eliminate exchange coupling between layers 12a and 12b (and between layers 14a and 14b). In addition, layers 12a and 12b have different coercive forces, and layers 14a and 14b have different coercive forces. Bias layers 12a and 12b are combined with decoupling layer 26 as a magnetic bias component, and layers 14a and 14b are also combined with decoupling layer 26 as a magnetic bias component. Magnetizations 18 a and 20 a provide magnetic bias 16 a to free layer 10 , and magnetizations 18 b and 20 b provide magnetic bias 16 b to free layer 10 . Magnetization 16 is determined by the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com