Novel photoresistance and its preparing method

A photosensitive resistor and photosensitive film technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of restricted entry and elimination, and achieve the effects of good consistency, simple methods, and reduced product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

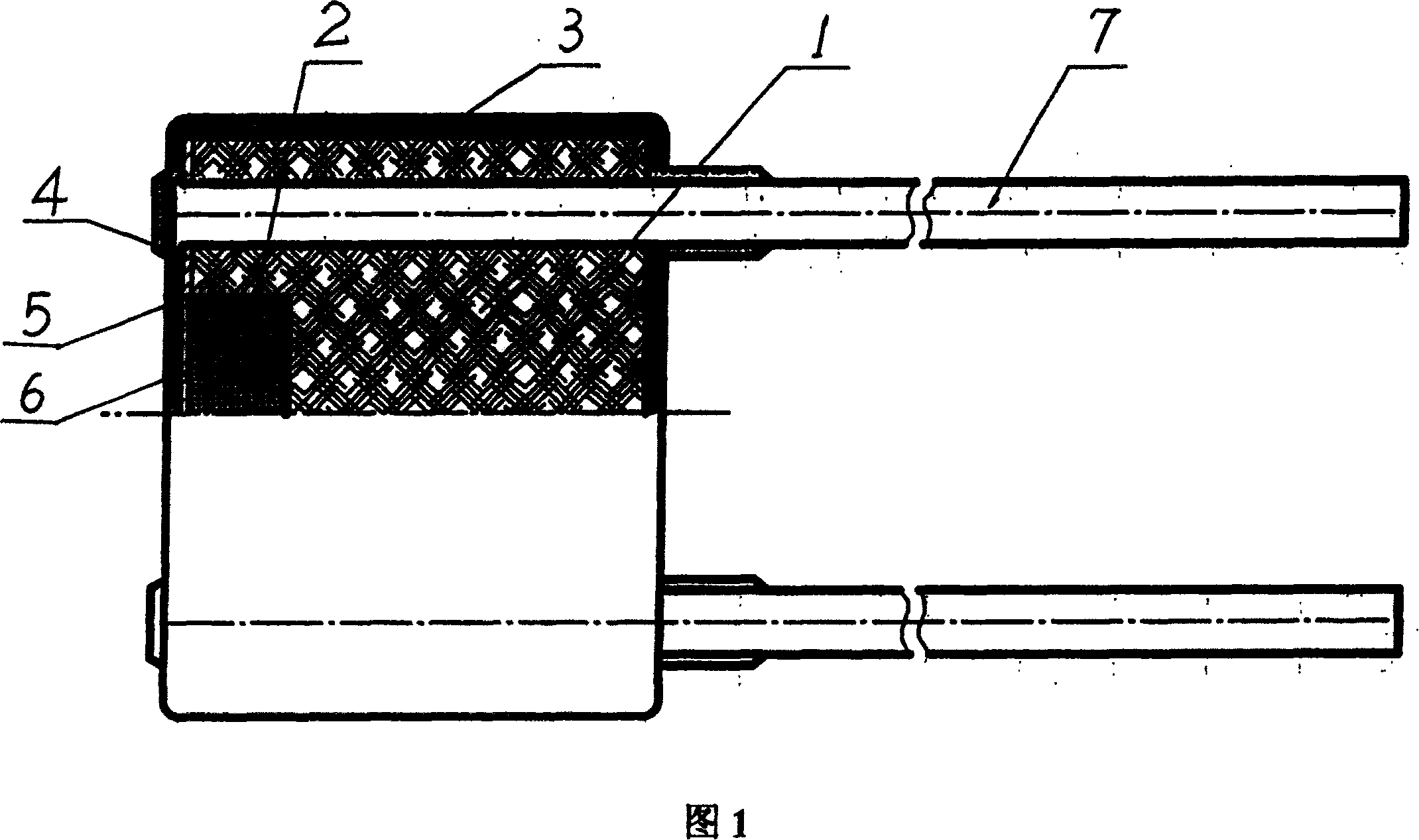

[0015] The present invention has Al 2 o 3 Ceramic base and Al 2 o 3 Ceramic substrate, with two holes on the ceramic base, in Al 2 o 3 A mixture of CdS and CdSe is coated on the ceramic substrate, and the mixture of CdS and CdSe is a mixed solution formulated with CdS and CdSe in a weight ratio of 90:10-60:40; high-temperature sintering forms a photosensitive film layer to make a photoresistor chip; in Al 2 o 3 There is an empty groove on the ceramic base, and the photoresistor chip is embedded in Al 2 o 3 In the cavity on the ceramic base, vacuum-coat Sn to form electrodes, and use conductive silver paste to connect the chip with the base and lead wires.

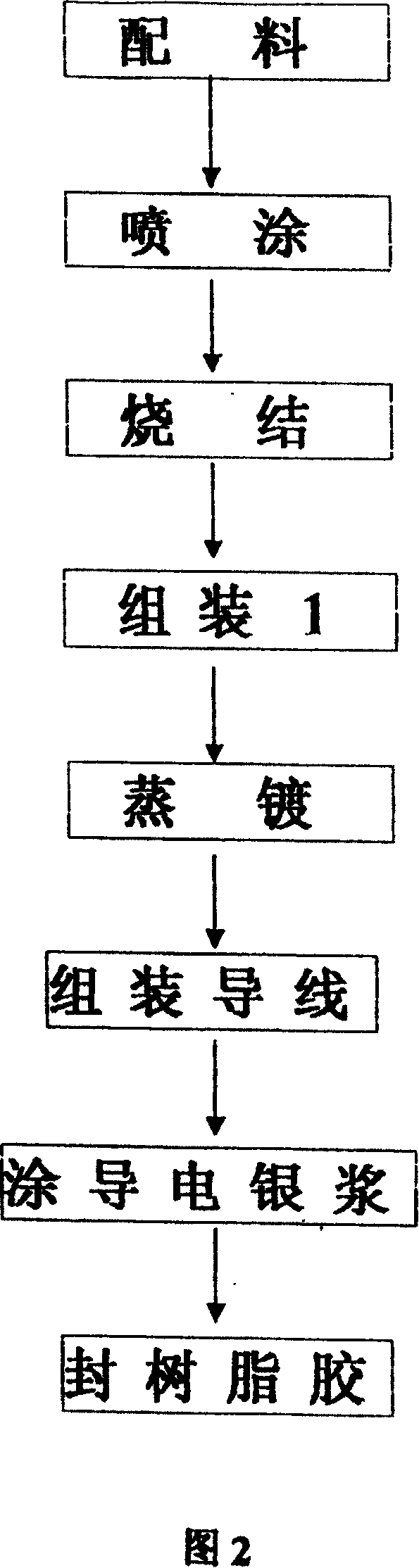

[0016] In order to be able to prepare above-mentioned product, the method that the present invention takes is as follows:

[0017] 1. Use Al with a purity of more than 95% 2 o 3 To make a rectangular or other shaped ceramic substrate, use Al 2 o 3 Make a ceramic base larger than the ceramic plate, leave an empt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com