Method and device for conditioning semiconductor wafers and/or hybrids

A hybrid circuit and temperature adjustment device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, single semiconductor device testing, etc., can solve the problems of large consumption of dry air, freezing of test wafers, etc., and achieve The effect of a high level of operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

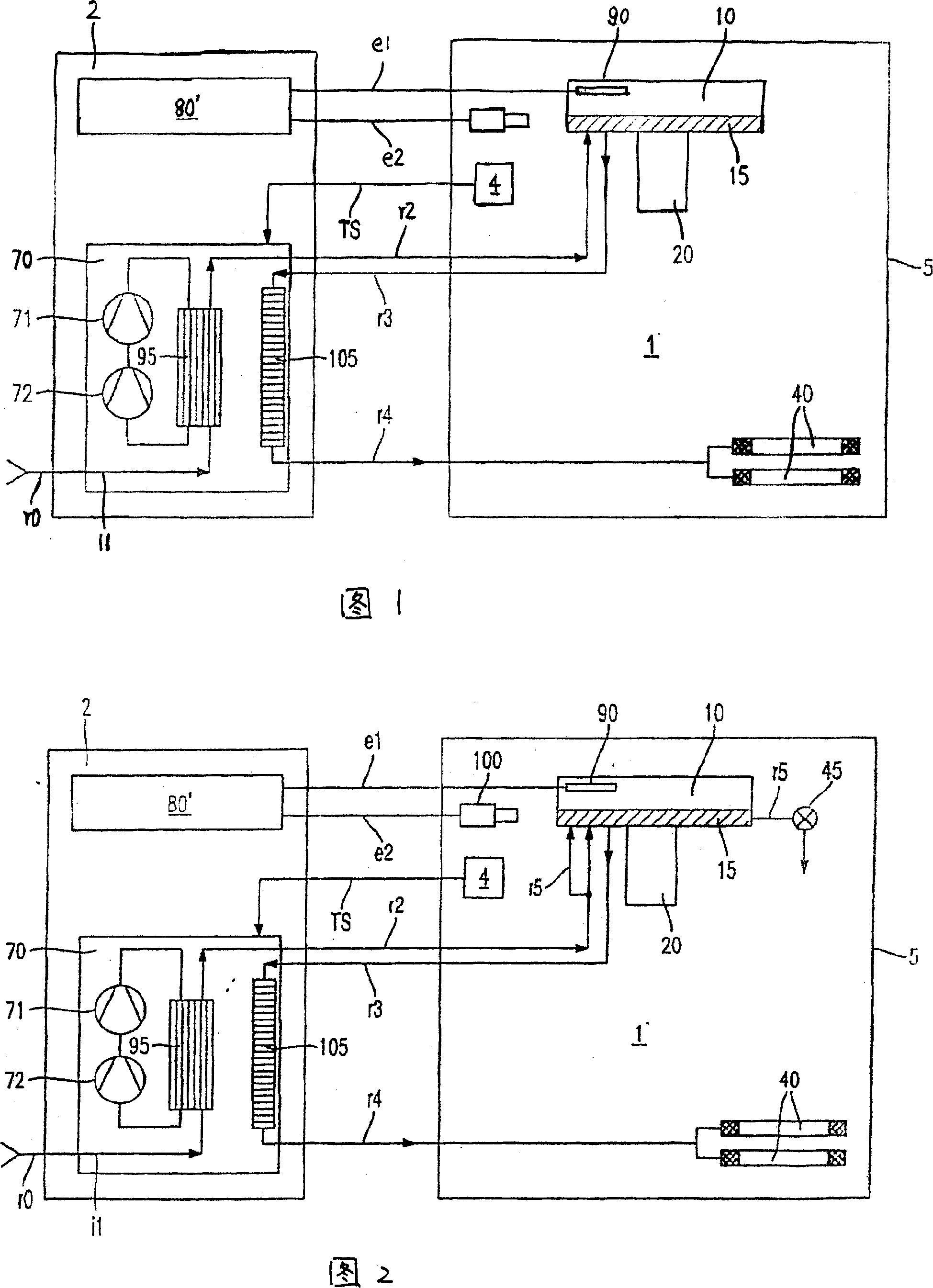

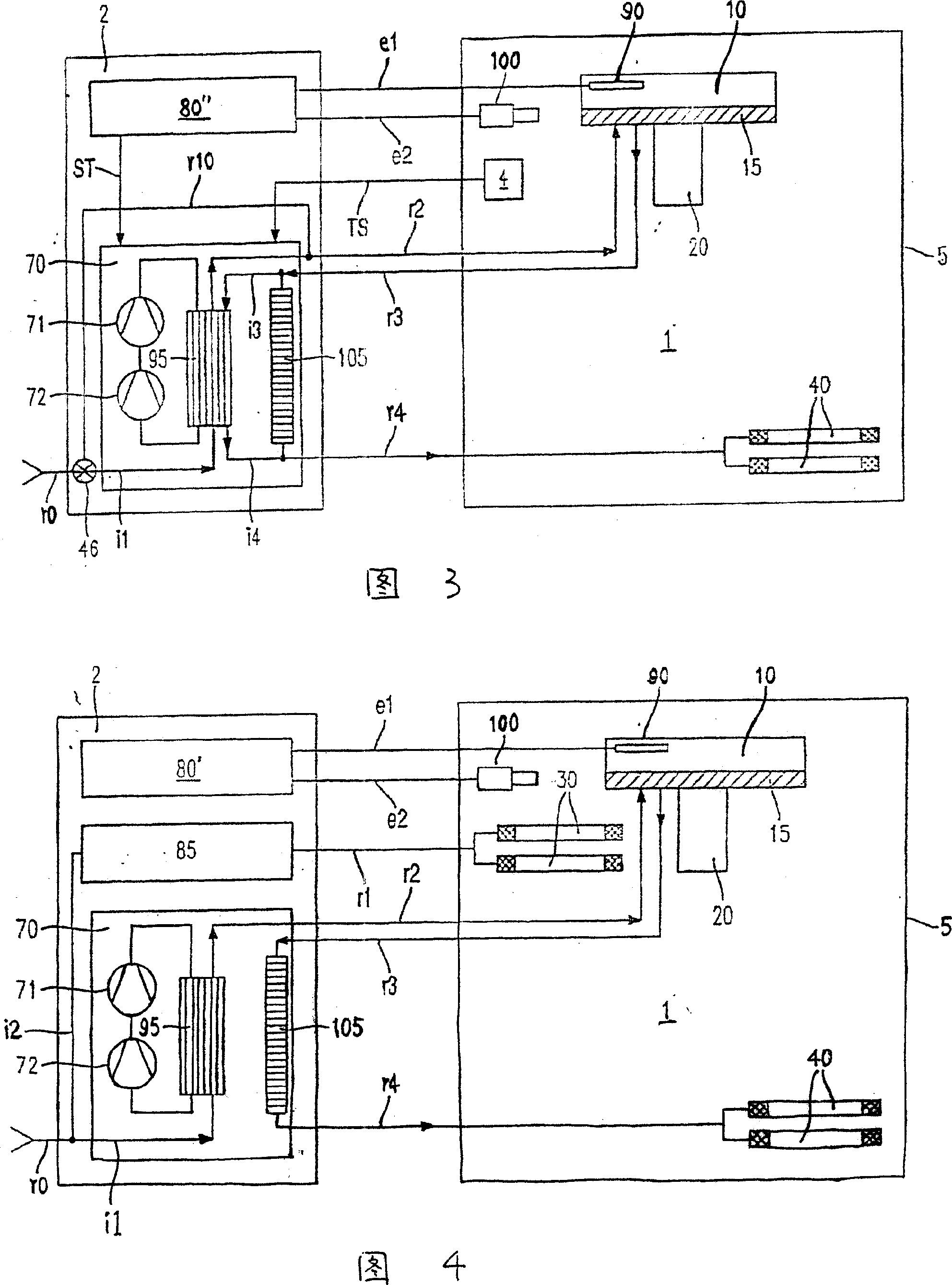

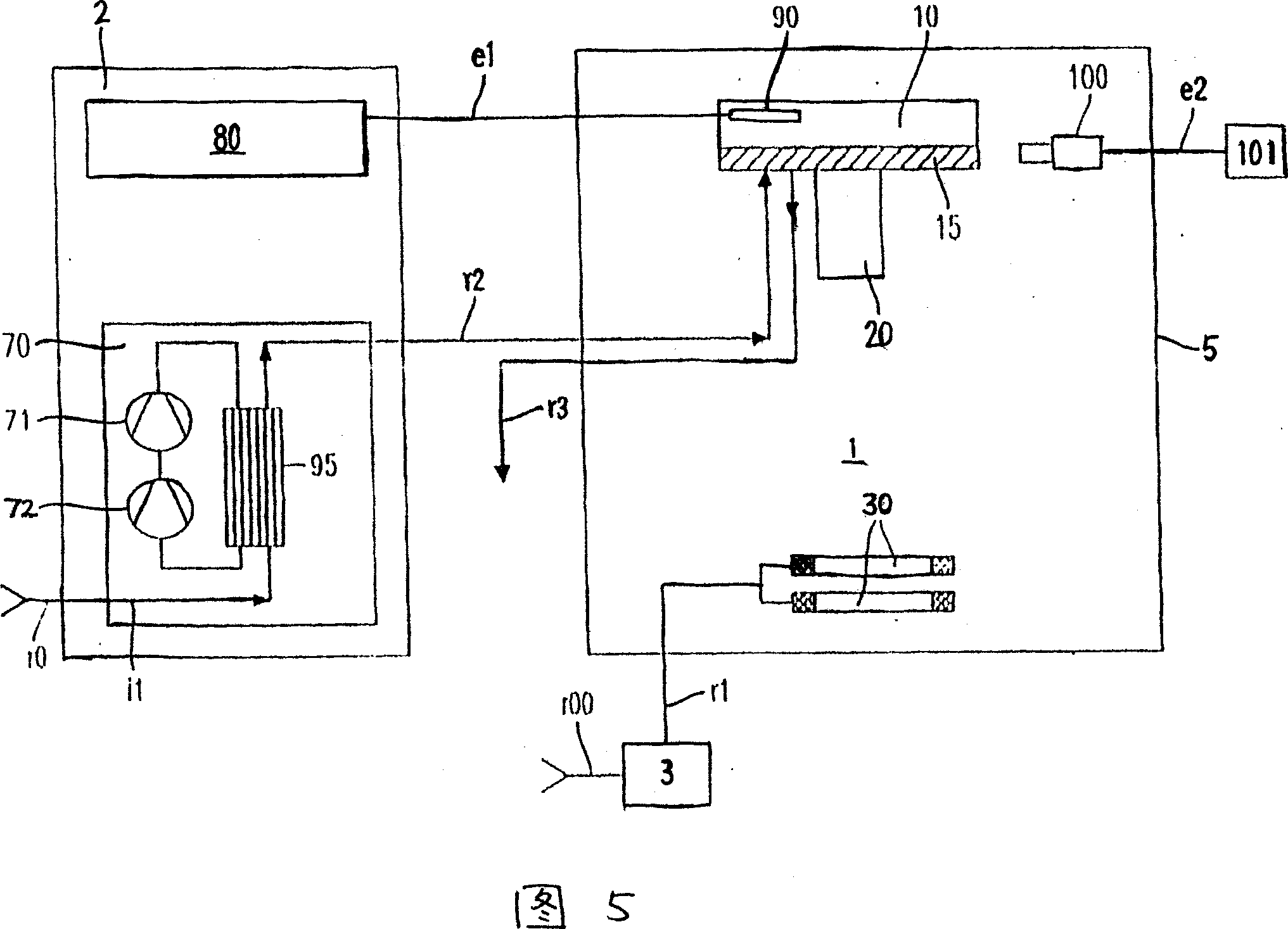

[0047] FIG. 1 is a schematic view of a first embodiment of an adjustment device according to the invention.

[0048] Components that have been described in the above description and in FIG. 5 are not described in the following description to avoid repetition.

[0049] Reference numeral 80' denotes a modified temperature controller, which can not only adjust the temperature of the sample rack 10 via the heating device 90, but also be connected to the dew point sensor 100 via a line 12. together and thus be able to automatically start compensatory heating when there is a risk of water / icing condensation.

[0050] In the embodiment according to FIG. 1 , a heating device 105 is added in the temperature regulation device 70 and is not in direct contact with the heat exchanger 95 . The line r3 does not terminate in the ambient air, but is directed into the heating device 105 so that the dry air that has left the sample holder 10 is returned, as it were, to the temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com