Cabo humidifying and charging machine

A feeder and tobacco stem technology, applied in tobacco, tobacco processing, application, etc., can solve problems such as loss, waste, and no aroma of tobacco stems, and achieve the effects of ensuring feeding accuracy, reducing production costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

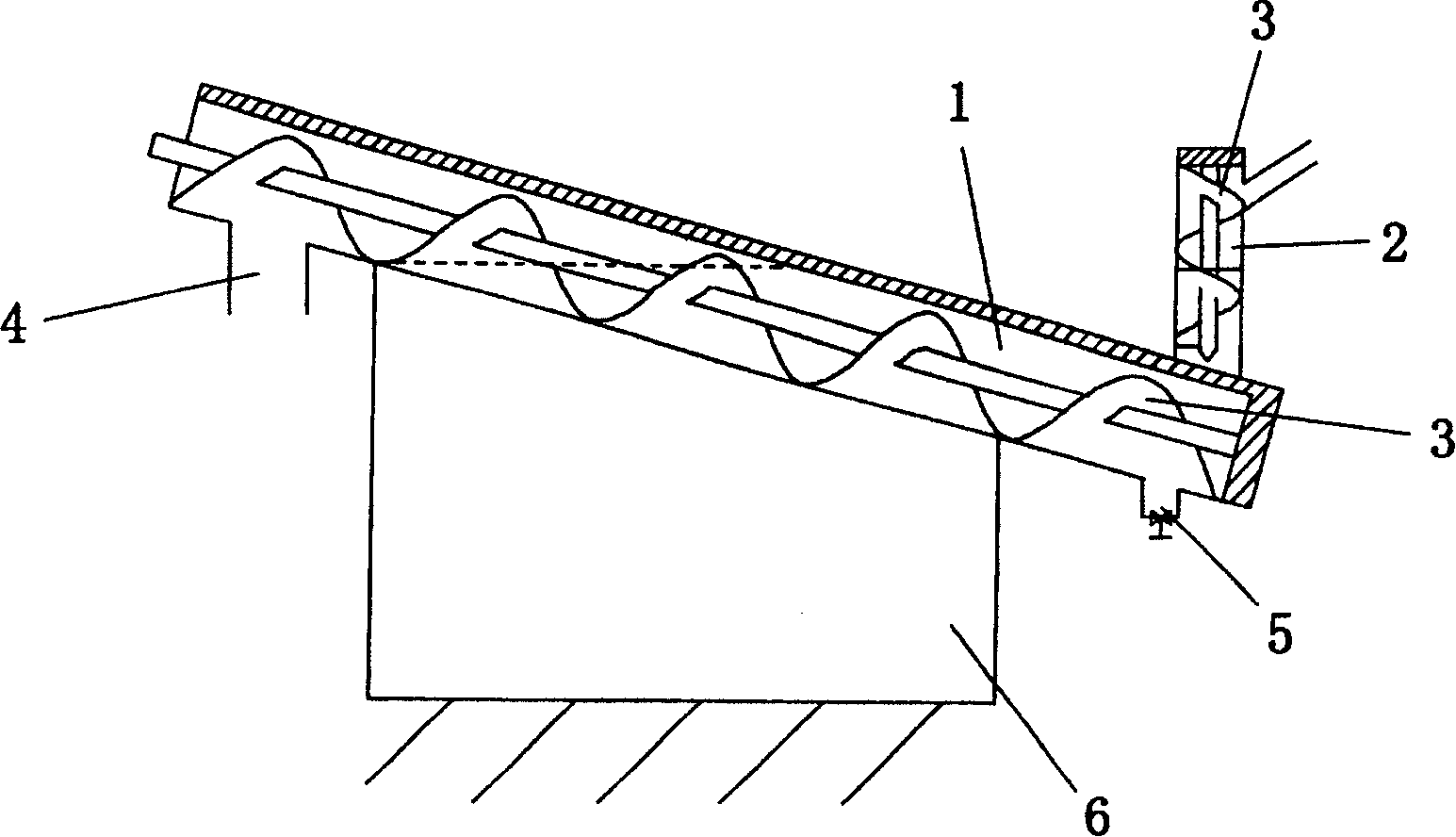

[0022] The present invention will be described in detail below in combination with specific embodiments and accompanying drawings.

[0023] A tobacco stem humidifying feeder provided by the present invention comprises a frame and an inclined long cylindrical container fixed on the frame. The feed liquid will not flow out from the feed opening, and ensure that the tobacco stems are fully soaked in the feed liquid; the container is provided with a screw feeder, and the upper part of the lower end of the container is provided with a feed port. The feeding port is connected with a feeding pipe, and the feeding pipe is provided with a screw feeder, so that the tobacco stems put in from the feeding port obtain power and enter the container from the feeding pipe, and then reach the high end from the low end of the container. The lower part of the high-end device falls down, and at the same time completes the process of moistening and feeding tobacco stems. The container can adopt a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com