Light-emitting diode support and producing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve the problems that the brightness performance of light-emitting diodes is not as good as expected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

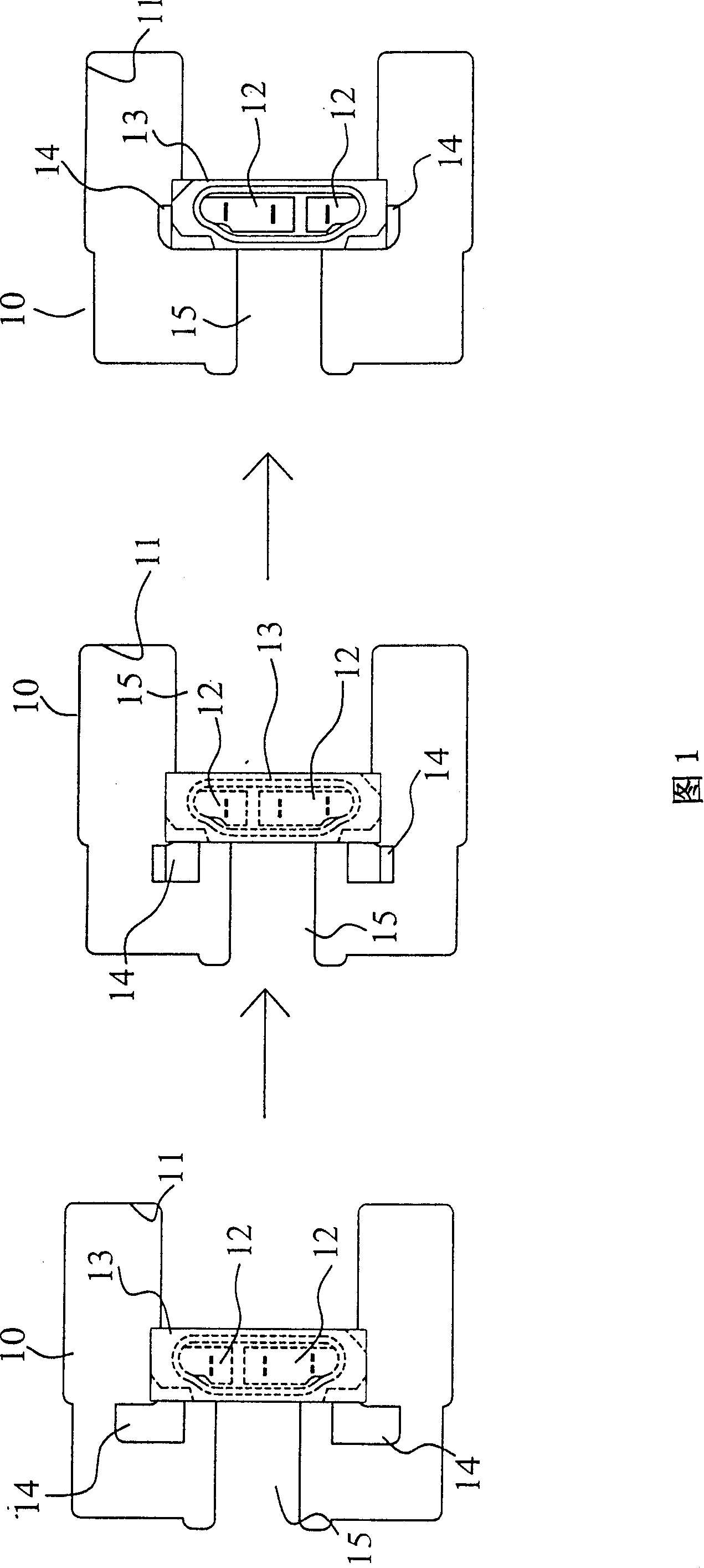

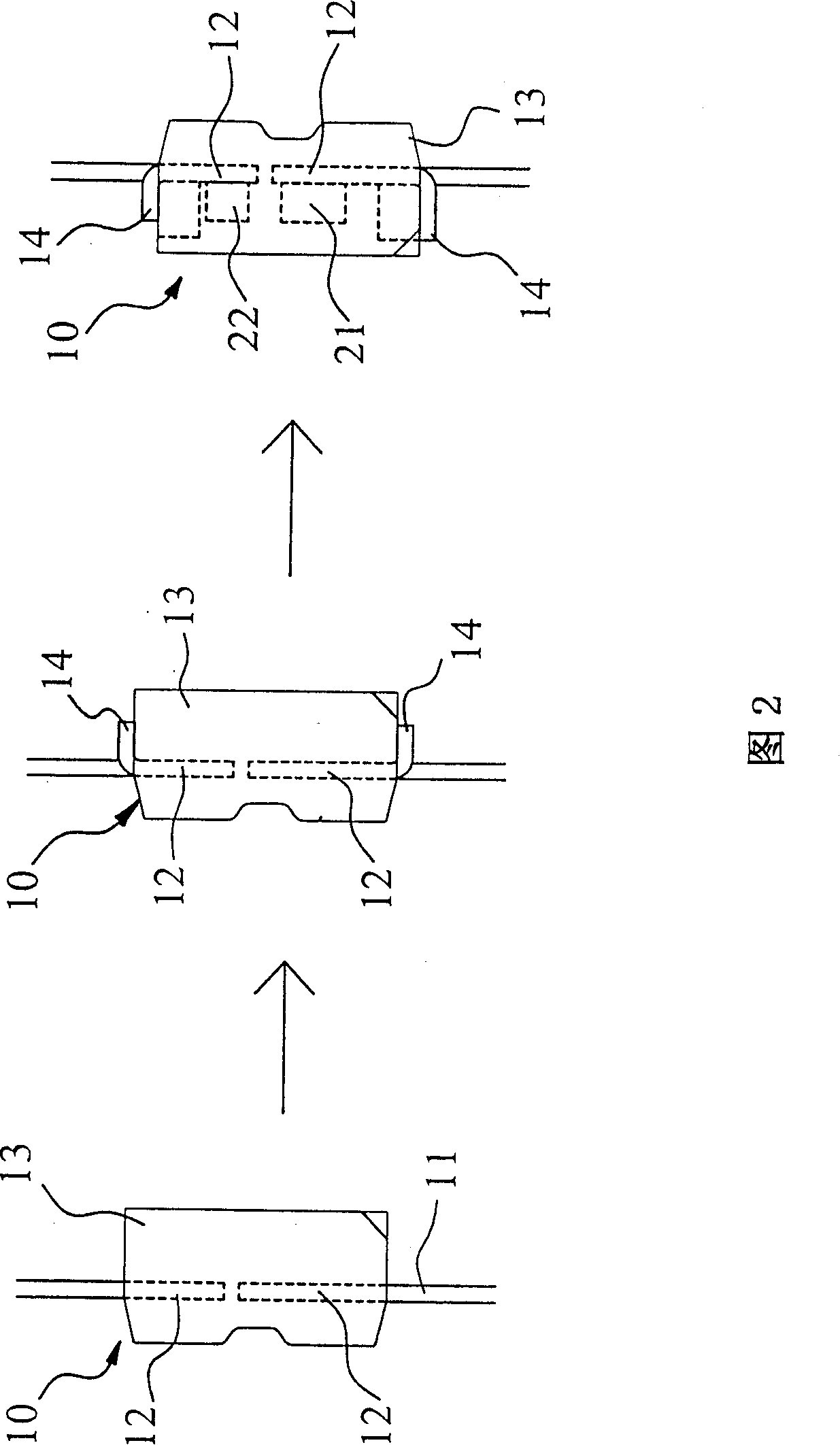

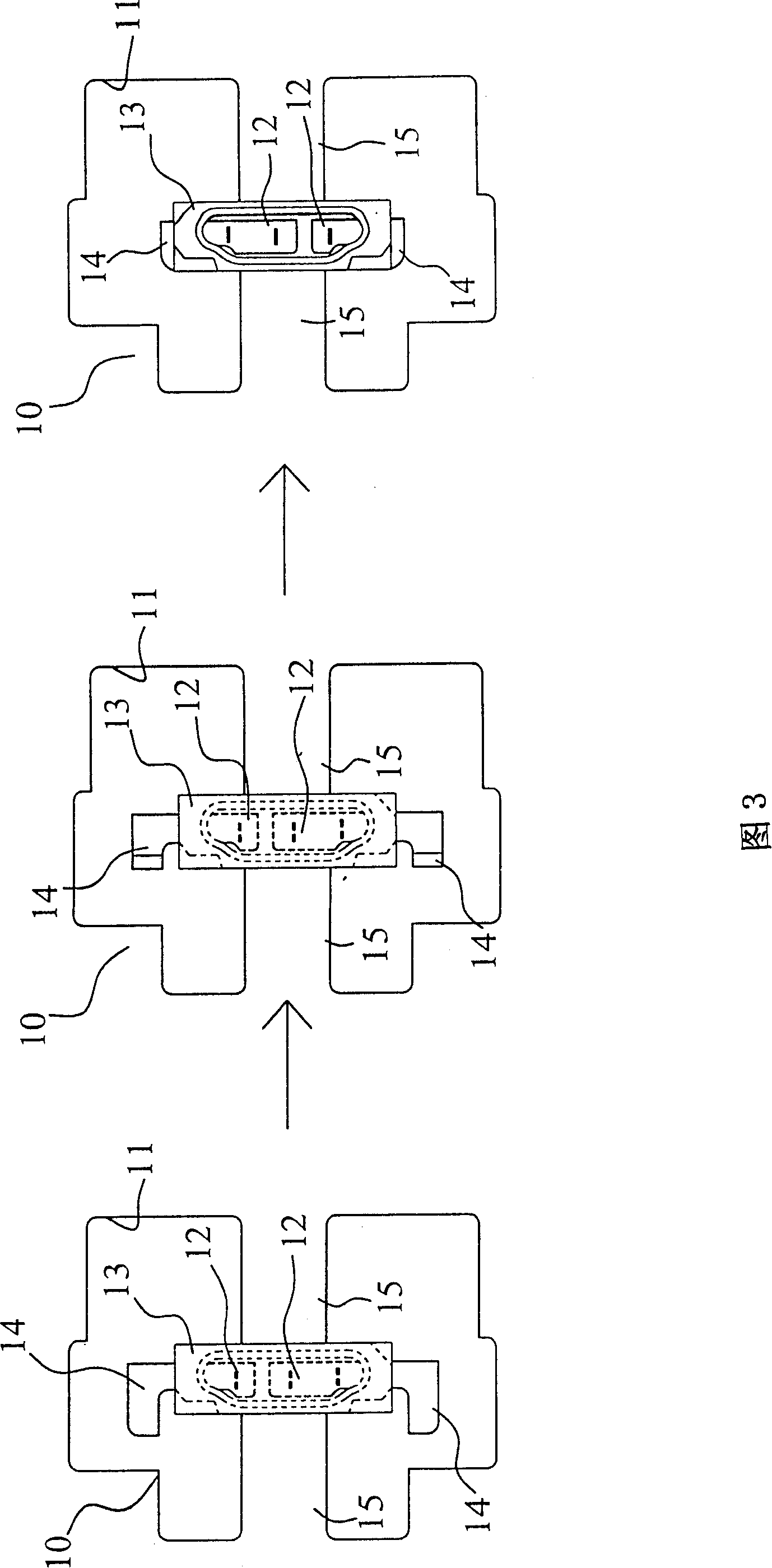

[0016] In order to make your examiners clear about the structure and composition of the present invention and the overall operation mode, the following descriptions are given with the drawings:

[0017] The present invention is a light-emitting diode bracket and a manufacturing method thereof. The manufacturing method of the integral bracket is shown in FIG. 3 and FIG. 4 , which is to punch and form two pieces on a flat metal strip 11 first in a stamping operation. The shapes of the bearing parts 12 corresponding to each other and the corresponding ends are not connected, one of the bearing parts 12 has a longer length, and at least one punching process is performed on the section of the bearing part 12 with the longer length, so that the bearing part 12 has a longer length. The section 12 forms a level different from the plate surface of the original metal strip 11, and then a plastic body 13 is formed on the sections of the two carrying parts 12 by injection molding, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com