Mixed aqueous dispersion of polyimide-fluororesin-polar crystal particulates and a method of producing the same

A polar crystal and polyimide technology, which is applied in the field of polyimide-fluororesin-polar crystal microparticle mixed aqueous dispersion and its preparation, can solve the problems of processing characteristics (safety, environmental load, and equipment cost) and other problems, to achieve the effect of excellent handling characteristics and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] The preparation method of this mixed aqueous dispersion comprises the steps of grinding and sieving the polar crystal microparticles to obtain polar crystal microparticles with a particle size of 3 μm or less, preparing the dispersion liquid 1 containing the aforementioned polar crystal microparticles, preparing Steps of dispersion liquid 2 of imide precursor or polyimide, preparation of dispersion liquid 3 containing fluororesin, and steps of mixing dispersion liquid 1, dispersion liquid 2, and dispersion liquid 3 above.

[0138] The preparation method of this mixed aqueous dispersion can further include, the step of adding potassium persulfate to water to prepare an aqueous solution of potassium persulfate, the step of preparing the dispersion 4 containing aluminum oxide, and mixing the entire dispersion with potassium persulfate The step of mixing the aqueous solution.

[0139] In another embodiment, the preparation method of this mixed aqueous dispersion comprises t...

Embodiment

[0156] The present invention will be described in more detail through examples below, but the present invention is not limited to these examples.

[0157]

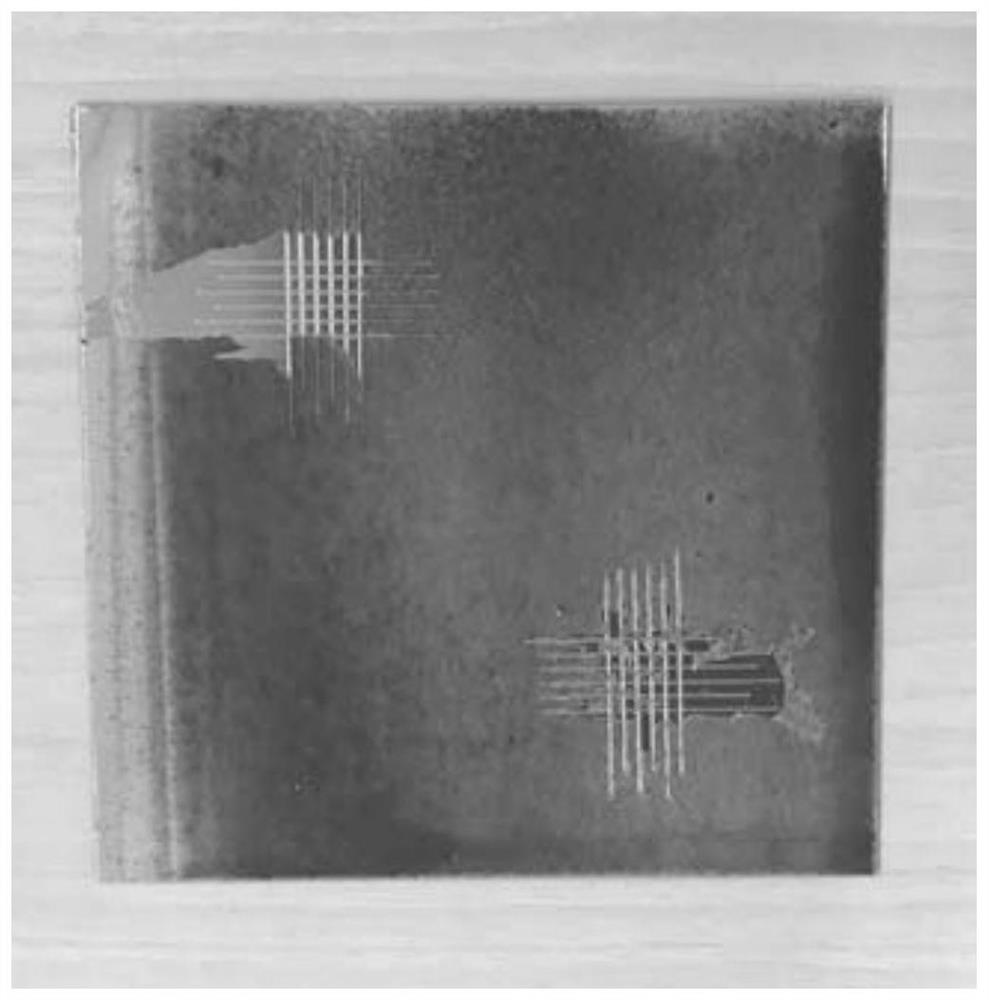

[0158] The performance of the aqueous dispersion of the present invention as a coating agent is confirmed by a 100-grid test.

[0159] The configurations and production methods of Examples and Comparative Examples are as follows.

[0160] (Example)

[0161] The compositions of the examples are shown below.

[0162] Polyimide dispersion liquid (W-20; manufactured by Nakata Coating Co., Ltd.): 30% by weight

[0163] PTFE dispersion (PTFE-D; manufactured by Daikin Industries): 70% by weight

[0164] Aluminum sol (Al-L7; manufactured by Taki Chemical): 5% by weight

[0165] Potassium persulfate: 1% by weight

[0166] Pink tourmaline dispersion: pink tourmaline (produced in Sri Lanka) with a particle size of 3 μm or less was prepared into 30%, 10%, and 5% dispersions.

[0167] The formulation of the examples is shown be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com