Disc brake comprising a lining support and its manufacturing mehtod

A disc type, brake technology, applied in the direction of brake type, brake parts, friction lining, etc., can solve the problems affecting the surface tension of the lining, and achieve the effect of optimizing the compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

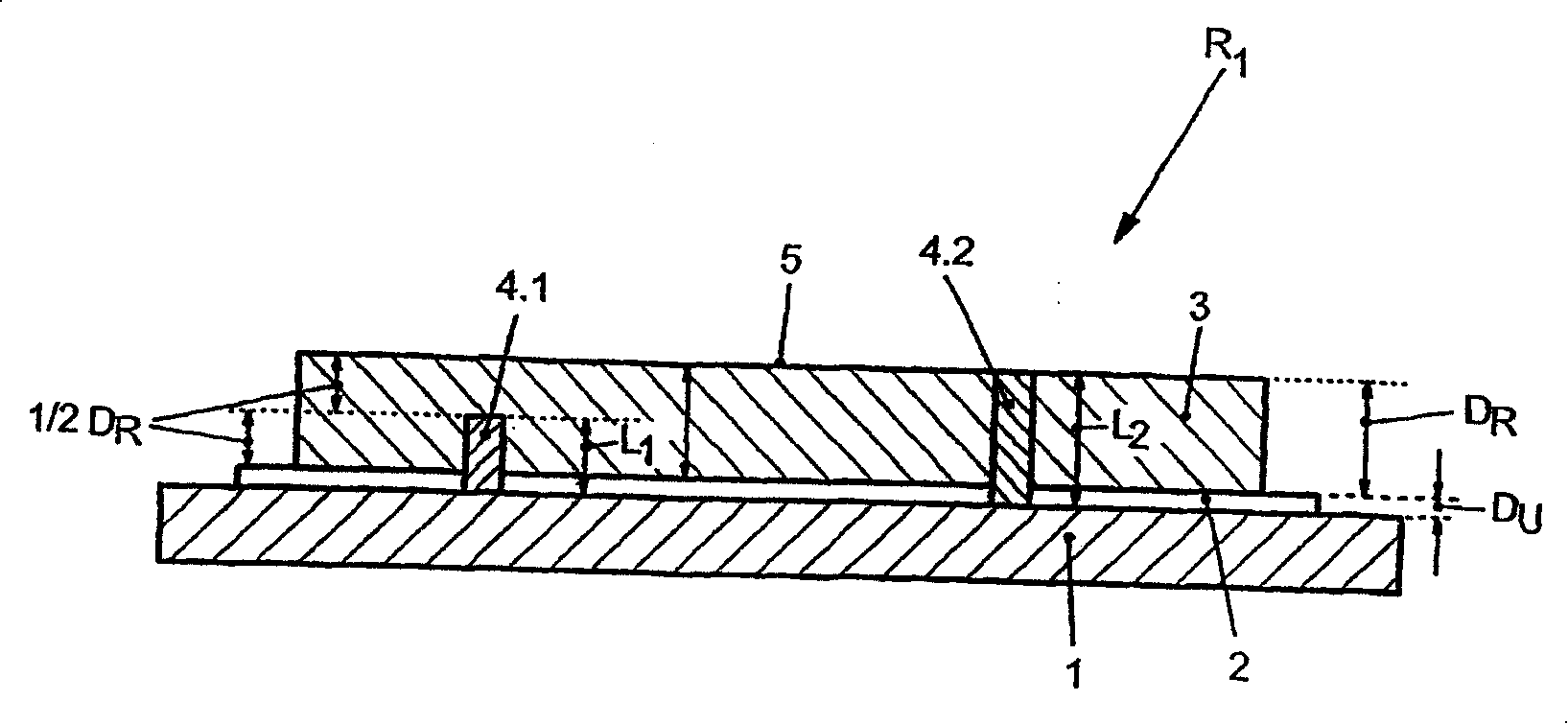

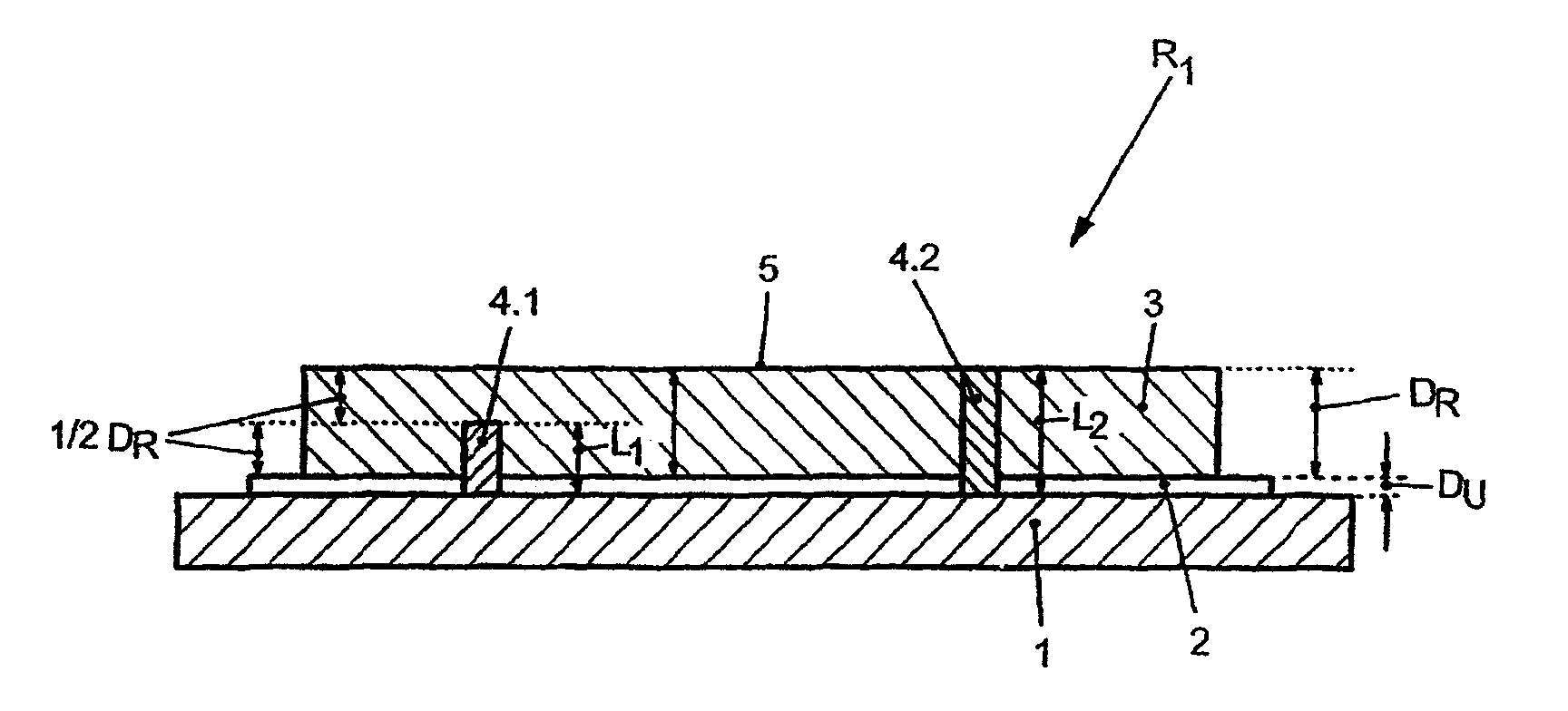

[0022] figure 1 With a brake shoe R 1 A disc brake not shown in detail is shown in cross section, the brake shoe R 1 The disc brakes are radially pressurized by means of brake calipers and brake pistons, not shown in the drawing. Brake shoe R 1 Essentially, it consists of a lining carrier 1 to which a so-called lower layer 2 is glued. The actual friction lining 3 is glued to the lower layer 2 , or is firmly connected to the lower layer 2 .

[0023] Under certain circumstances, the lower layer 2 can be omitted, in which case the friction lining 3 is glued directly to the lining carrier 1 .

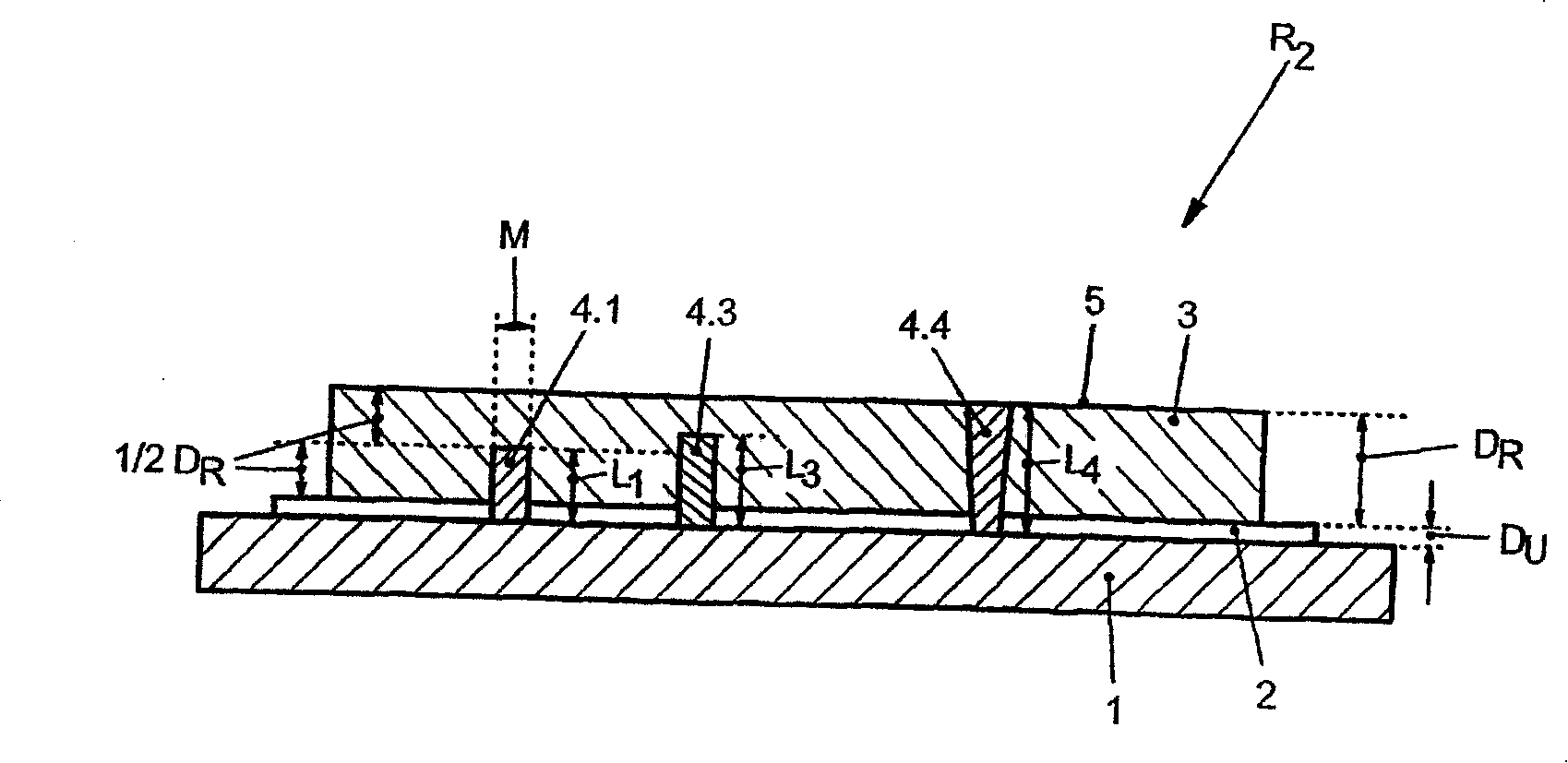

[0024] A secure connection of at least one screw 4.1 to 4.4 to the lining carrier 1, in particular a secure welding thereto, is of special significance in the context of the invention. here as also figure 2 As shown in , the bolts 4.1 to 4.4 are made of a soft material, in particular soft brass, preferably MS60, and are securely welded to the lining carrier 1, which is preferably mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com