Method and device for forming objects from a material strand and for separating said objects

A technology for processing forming and material strips, applied in metal processing and other directions, can solve the problems of easy to form breakage, such accuracy cannot be simply estimated, and troublesome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

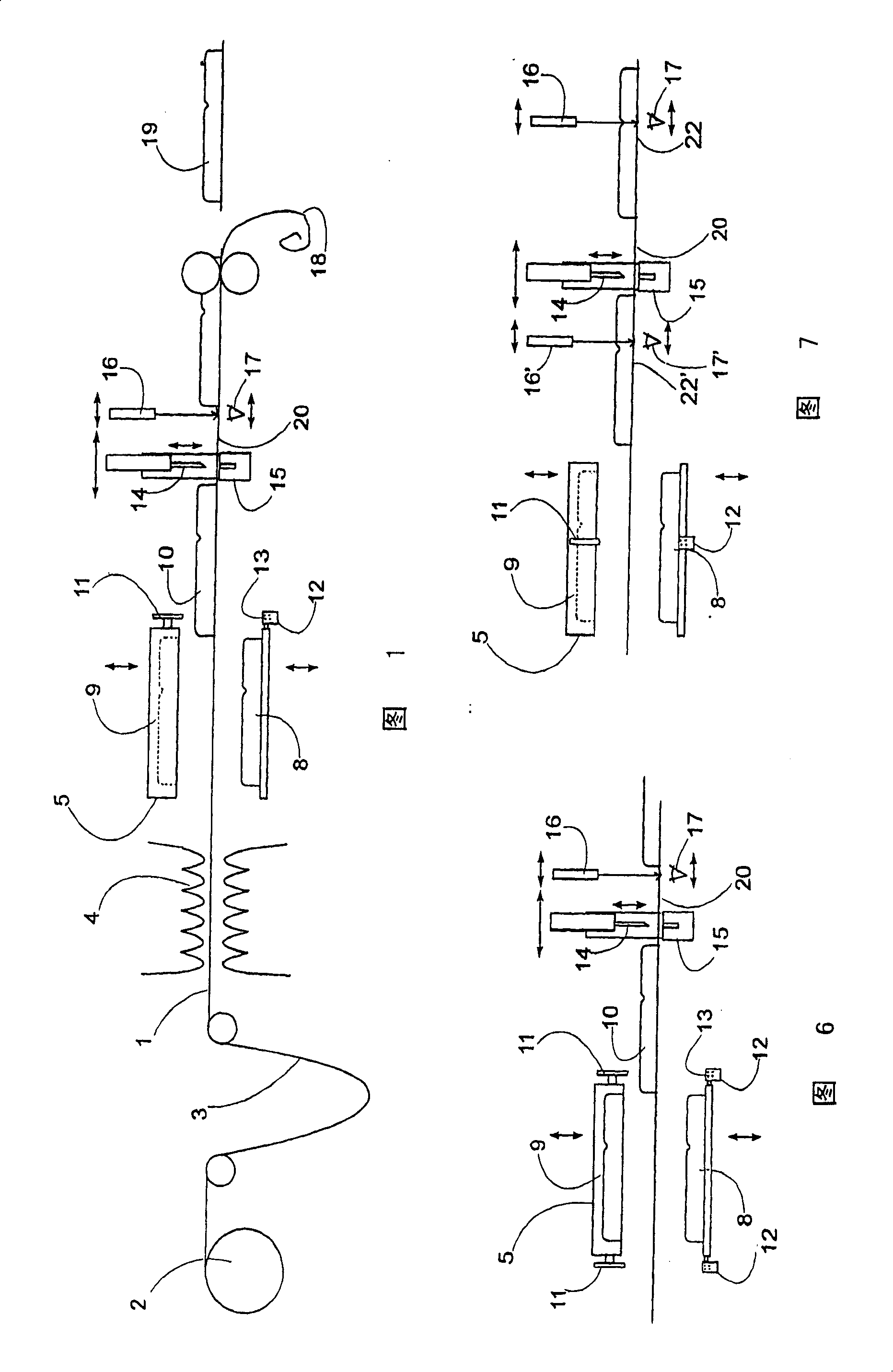

[0026] FIG. 1 shows a schematic side view of a device for producing a door inner panel of a refrigeration appliance door from a material strip of polystyrene or another suitable plastic. The material strip 1 is unrolled from a storage drum 2 and passes one after the other along a transport path through a buffer section 3 , a heating device 4 , a die 5 , a cutting device 6 and a longitudinal cutting device 7 . The material strip 1 is transported step by step along the transport path from the heating device 4 to the longitudinal cutting device 7 . The buffer section 3 is used to quickly feed the necessary length of the material strip 1 in each conveying step, without the need for a sudden acceleration of the accumulator drum, which may have a considerable mass, for this purpose.

[0027] The heating device 4 consists of two elements which are respectively arranged above and below the material strip 1 and which heats the material strip to a temperature at which the material strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com