Device for producing a gas cushion

An air cushion and gas technology, applied in glass forming, glass remolding, manufacturing tools, etc., can solve problems such as damage to the optical properties of glass plates, and achieve the effect of eliminating cooling shadows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

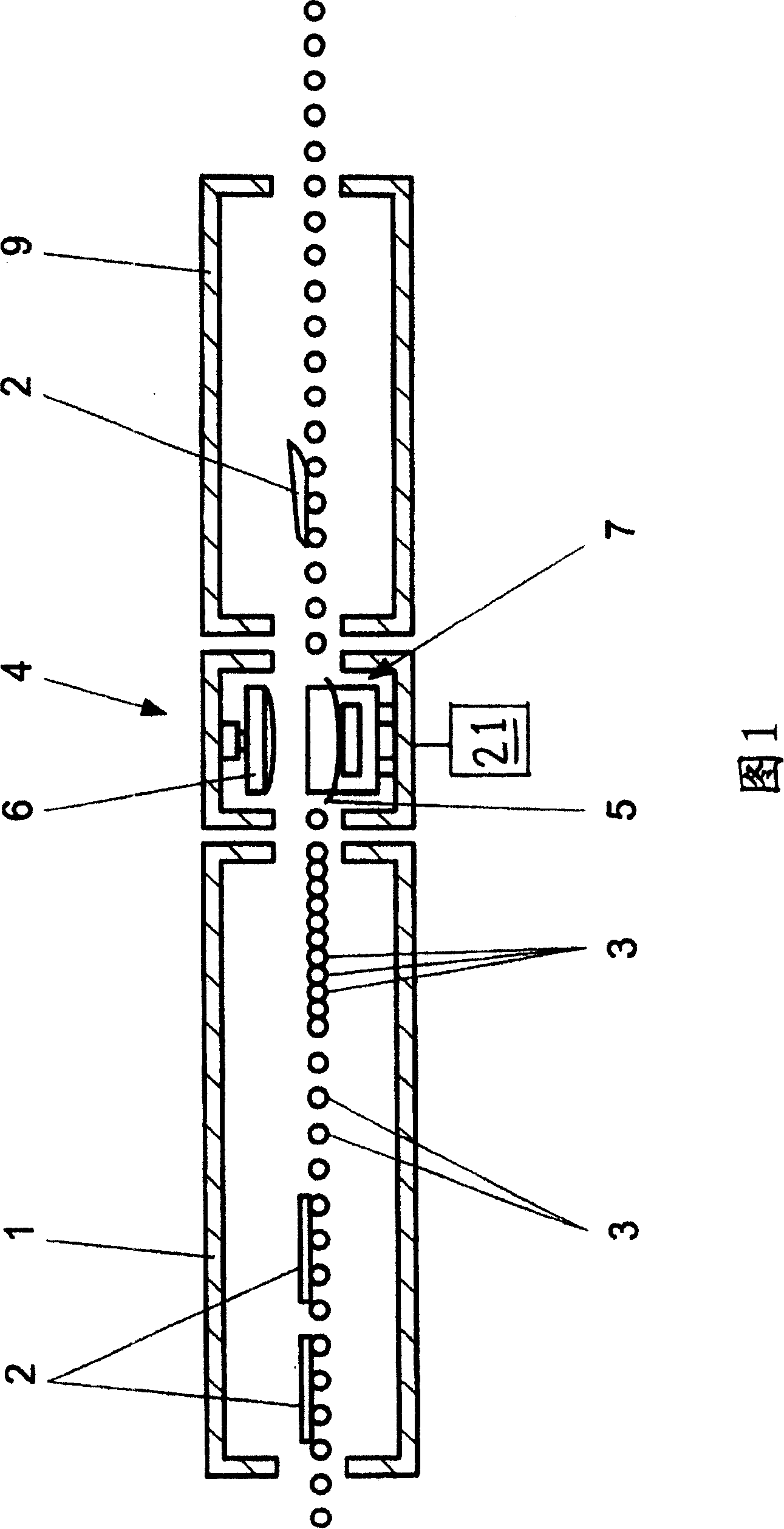

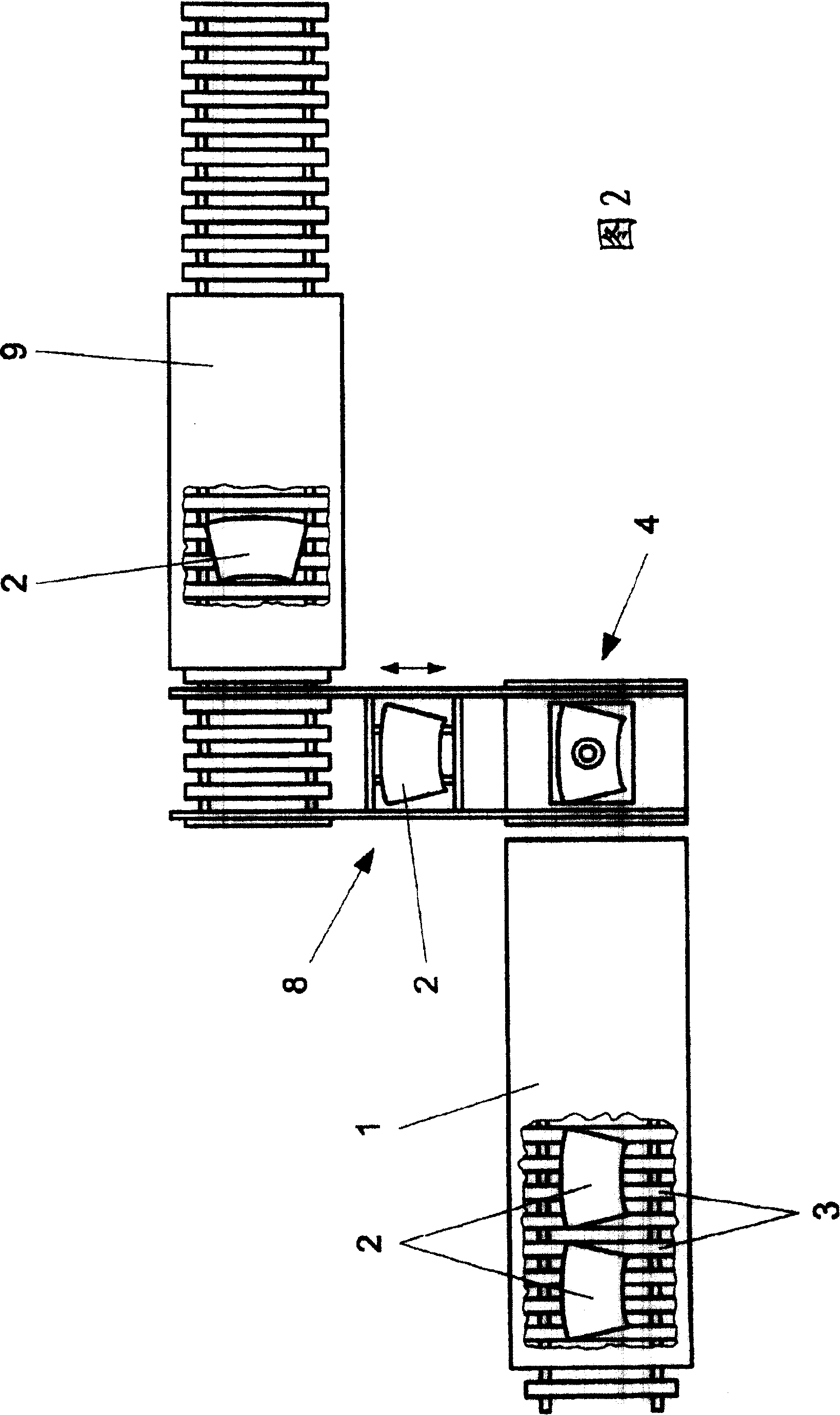

[0032] The plant according to FIGS. 1 and 2 has a preheating furnace 1 for preheating the glass panes 2 of a pair of glass panes. The glass sheet 2 is advanced through the furnace on rollers 3 whose spacing is reduced in the region of the furnace exit, since the heated glass sheet is deformable and thus requires stronger support. Behind the preheating furnace 1 there is a bending station 4 equipped with an annular glass bending mold 5 and a full-surface contact vacuum mold 6 conforming in contour and profile to the desired shape of the glass sheet after bending .

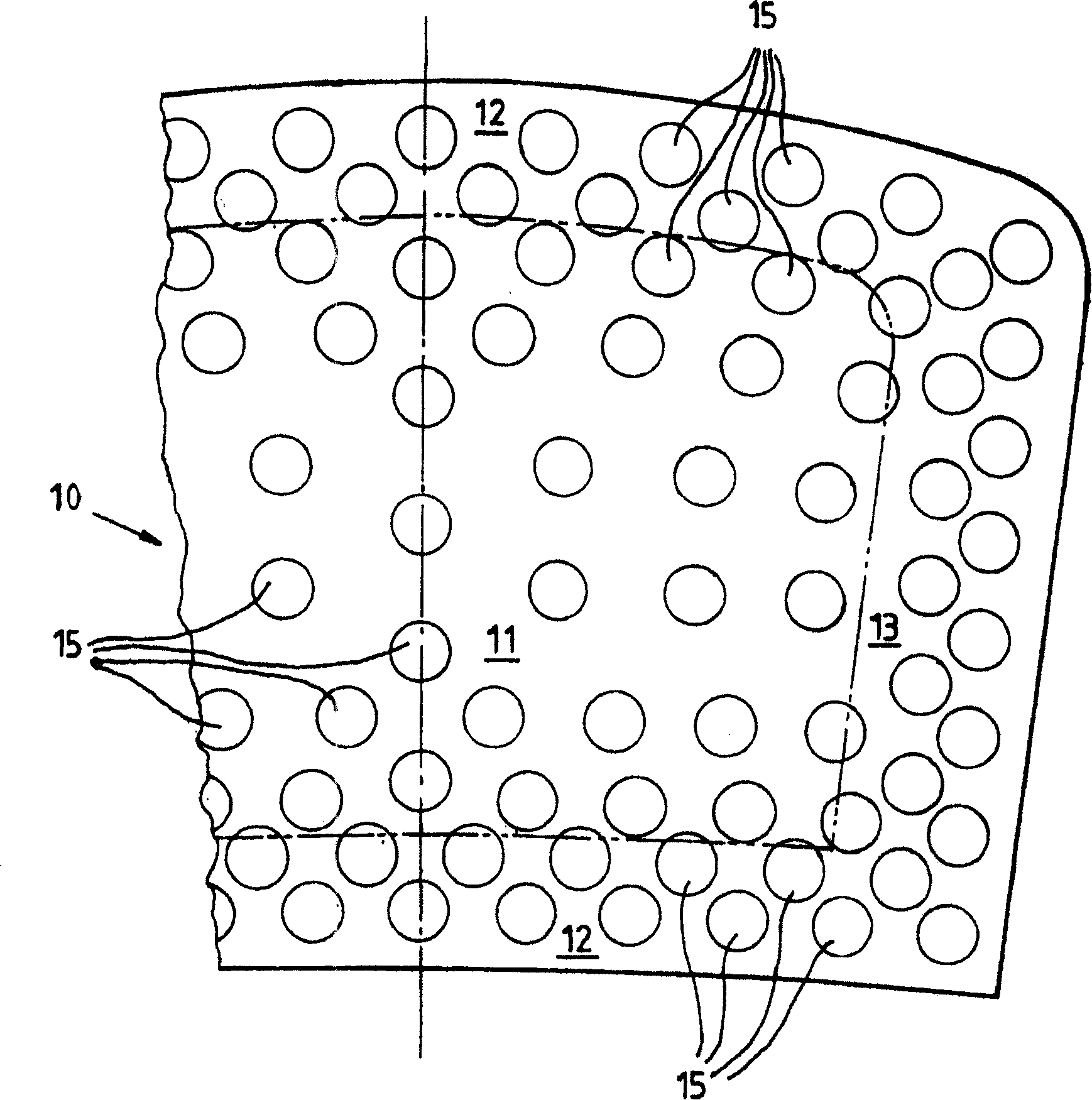

[0033] The invention relates in particular to a gas chamber 7 for generating a gas cushion, illustrated in FIG. 1 . The chamber 7 has an upper wall 10, as in image 3 and 4As shown in a partial plan view and surrounded by an annular die 5 . The upper wall, broadly speaking, can also conform in profile and section to the desired shape of the glass sheet to be produced, allowing for the fact that, as mentioned befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com