High anti-static high efficiency light-emitting diode and producing method

A technology of light-emitting diodes and diodes, which is applied to circuits, electrical components, and electric solid-state devices. It can solve problems such as poor heat dissipation characteristics of sapphire and GaN materials, accelerated chips, and chip failures, so as to improve reliability and service life, reduce Absorb and enhance the effect of anti-static discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

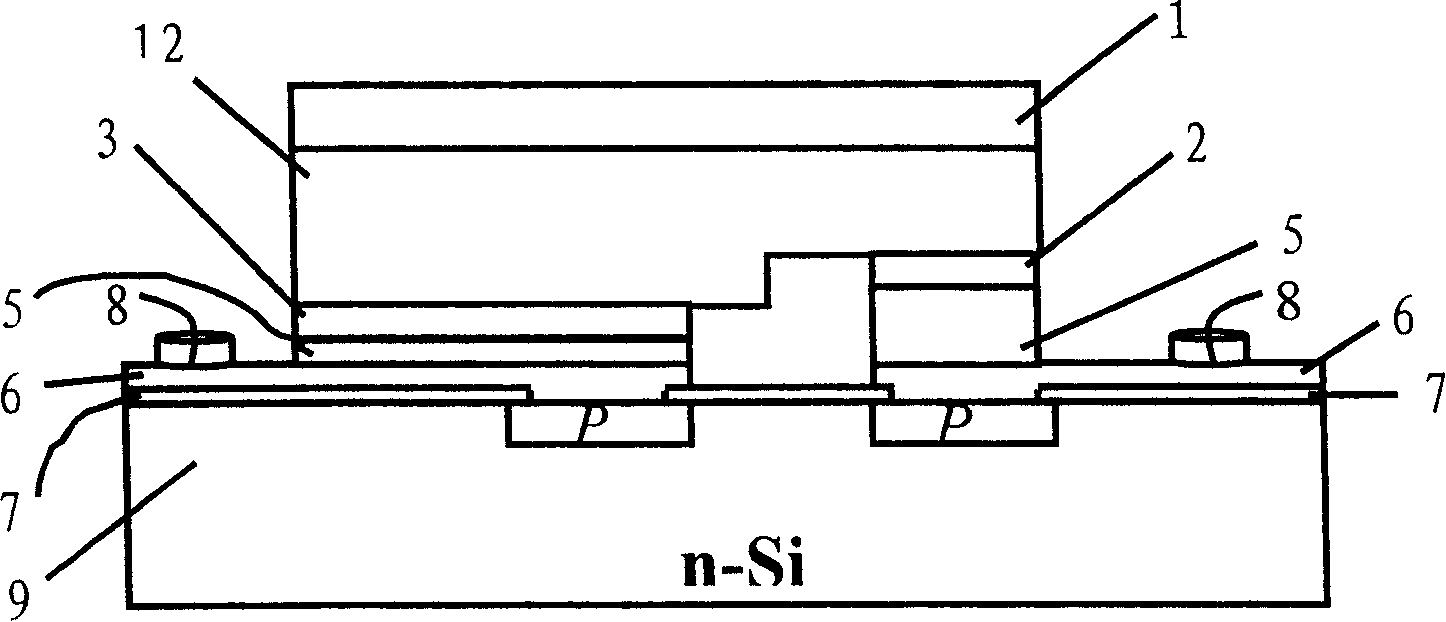

[0035] The structure of the high antistatic and high efficiency light emitting diode of the present invention is as Figure 1-3 As shown, the structural principle is as Figure 4 As shown, its production method is as follows:

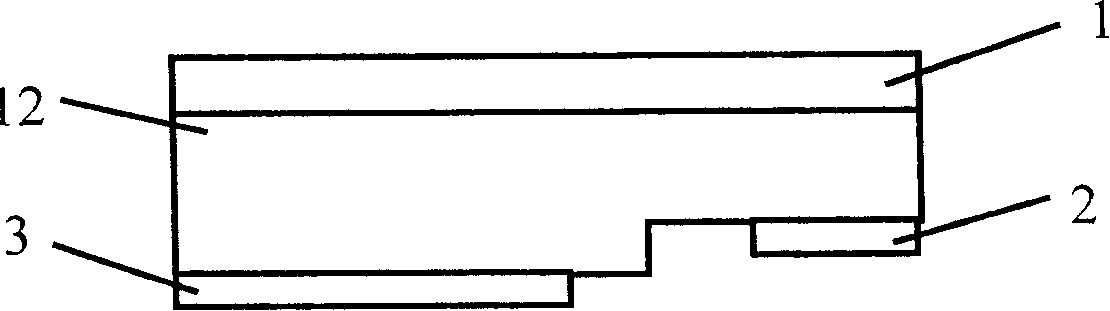

[0036] 1) First make the structure of the light-emitting diode according to the existing manufacturing process, and then make the entire N-type electrode layer (titanium / aluminum / titanium / gold) 2 and the P-type electrode layer (nickel / gold / titanium / Gold) 3, such as figure 1 shown;

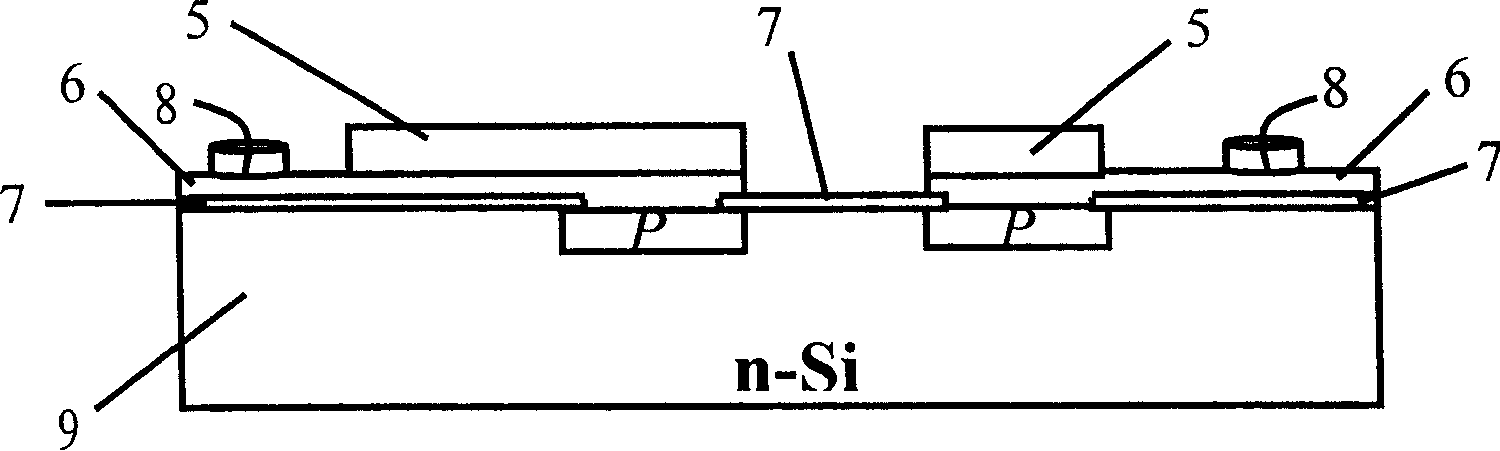

[0037] 2) Select a heavily doped N-type single-sided polished single-crystal silicon wafer as the substrate, and oxidize it at 1100-1150°C to form an oxide layer 7 with a thickness of 8000 (Angstrom) - 1 micron;

[0038]3) Photoetching the oxide layer 7 to form a diffusion window, using ion implantation or high temperature (1100-1150°C) to diffuse P-type impurities, and the junction depth is about 1 micron to form a high-concentration P-type structure;

[0039] 4) We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com