Method for improving permanent-magnetic linear motor motion precision

A permanent magnet linear motor, motion accuracy technology, applied in the estimation/correction of motor parameters, non-electric variable control, AC motor control, etc. Increased control complexity and improved output fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

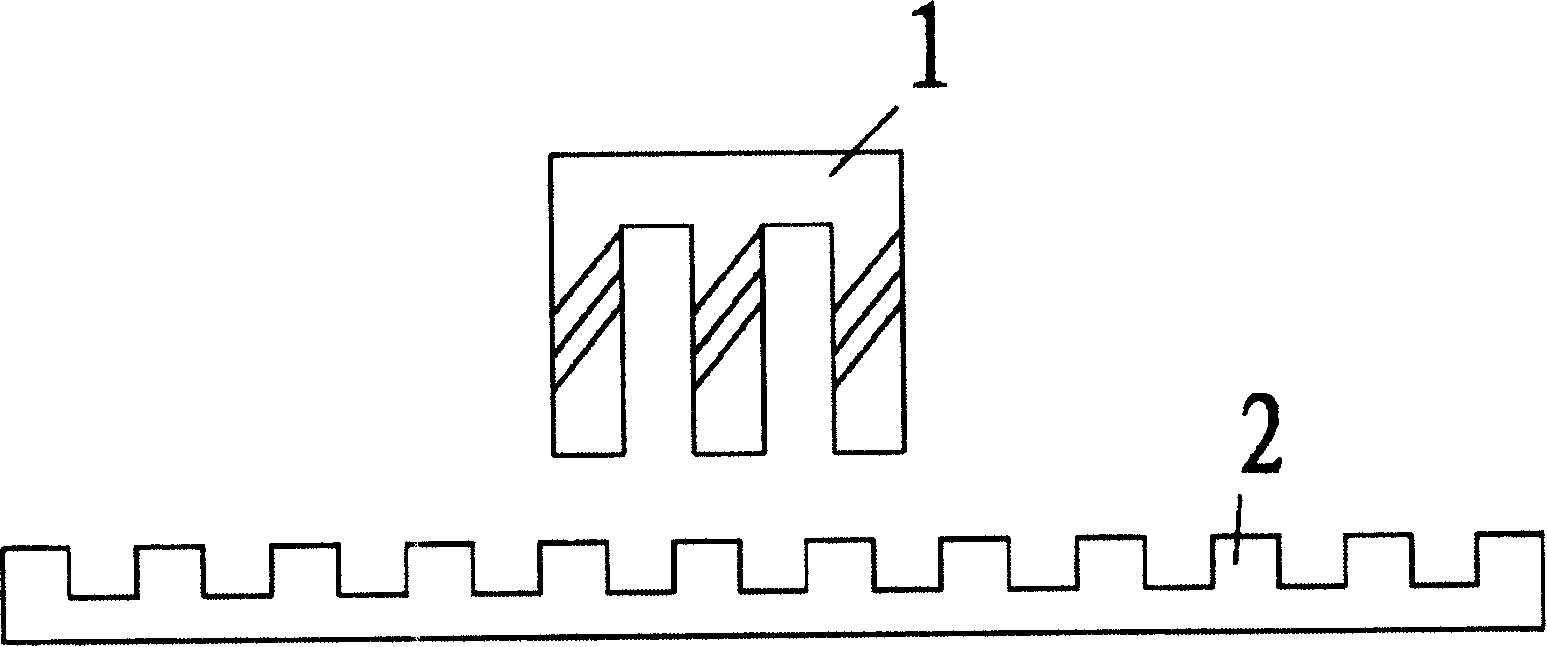

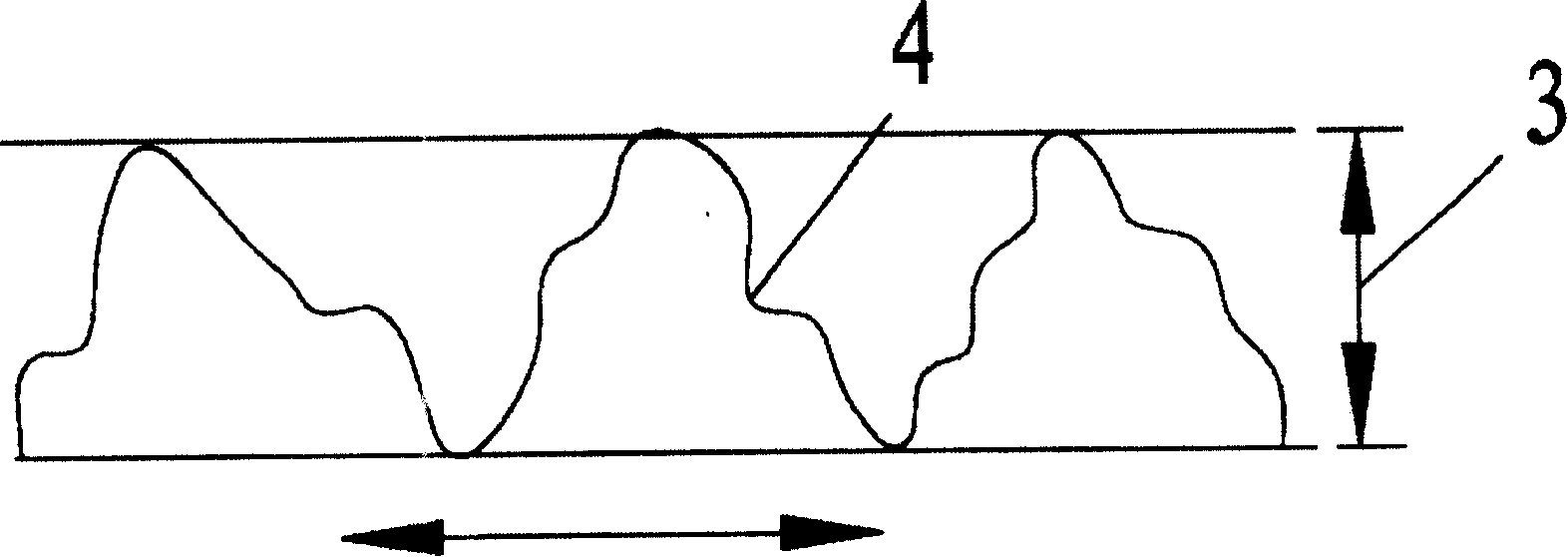

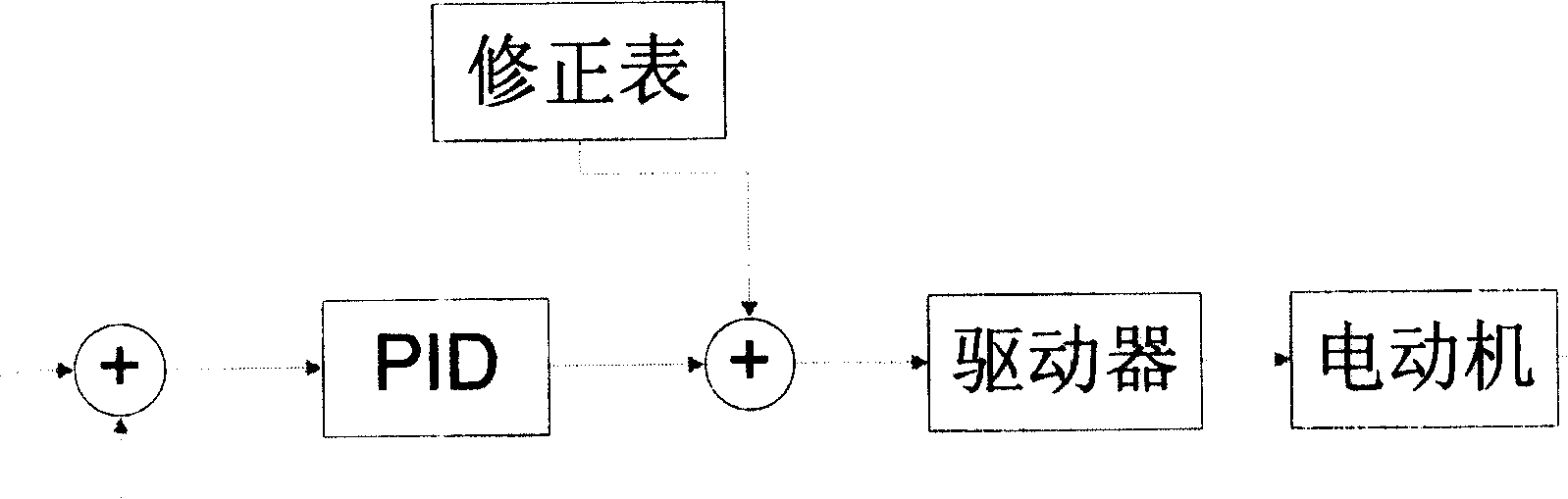

[0018] The invention relates to a method for improving the motion precision of a permanent magnet linear motor. A specific embodiment of the present invention is as follows: first clear the feed-forward signal table, and the size of the table is determined according to the computing capability and motion range of the system. Then, control the motor to move to the initial position, and move to the final position at a slower speed (the magnetic force influence can be accurately compensated); utilize a position acquisition sensor, such as a known encoder, a grating ruler, which can acquire the position by relative movement Information, the accuracy can reach the micron level, the actual displacement information is collected, and the electromagnetic force corresponding to each position is collected at the same time (the current value of the corresponding motor is converted into a force value, and the relationship between the current and the force value is linear). Then move from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com