Temperature compensating crystal oscillator structure and its manufacturing method

A technology of temperature compensation and manufacturing method, applied in the direction of power oscillator, electrical components, etc., can solve the problems of customer interference, difficulty, small distance, etc., and achieve the effect of low cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

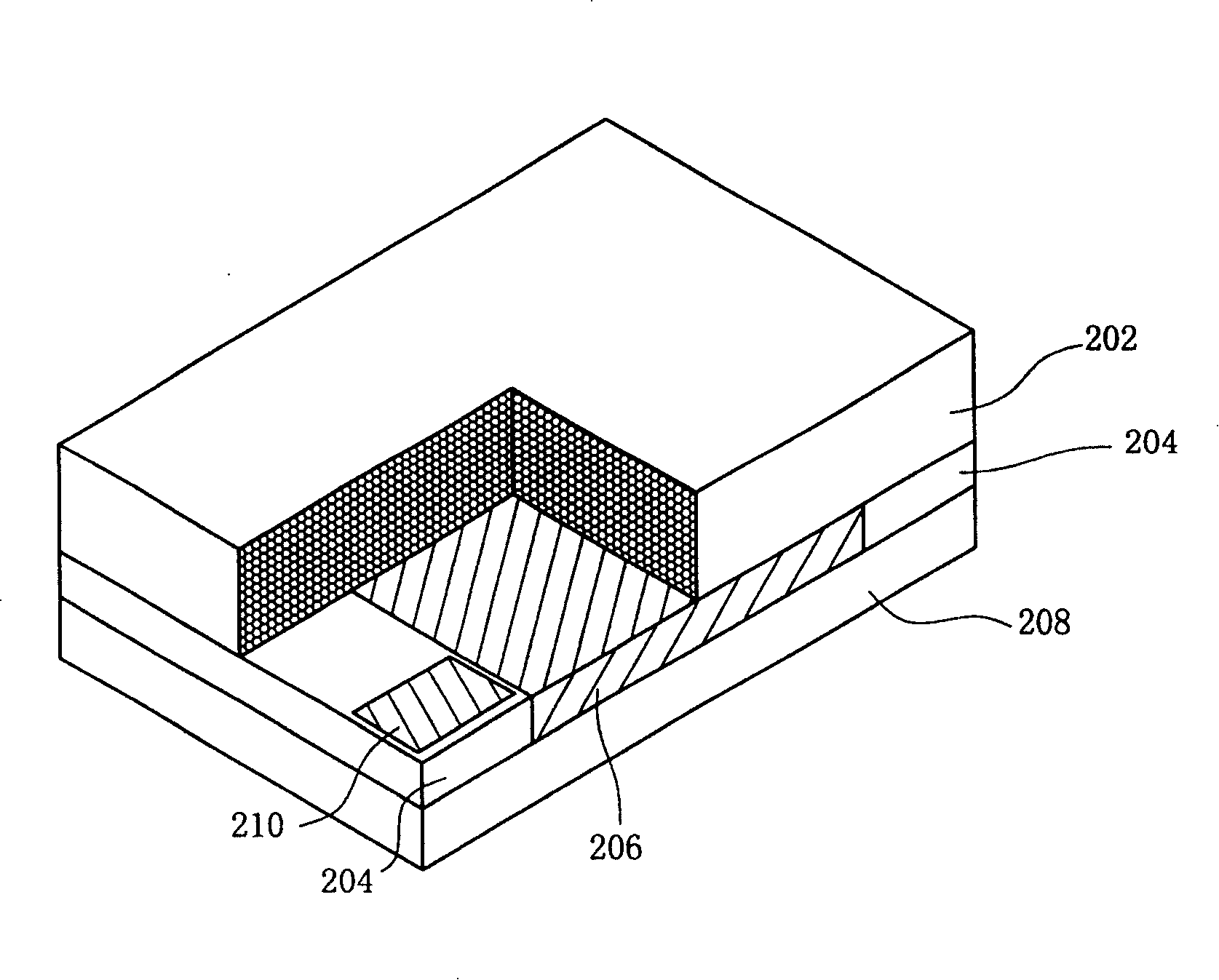

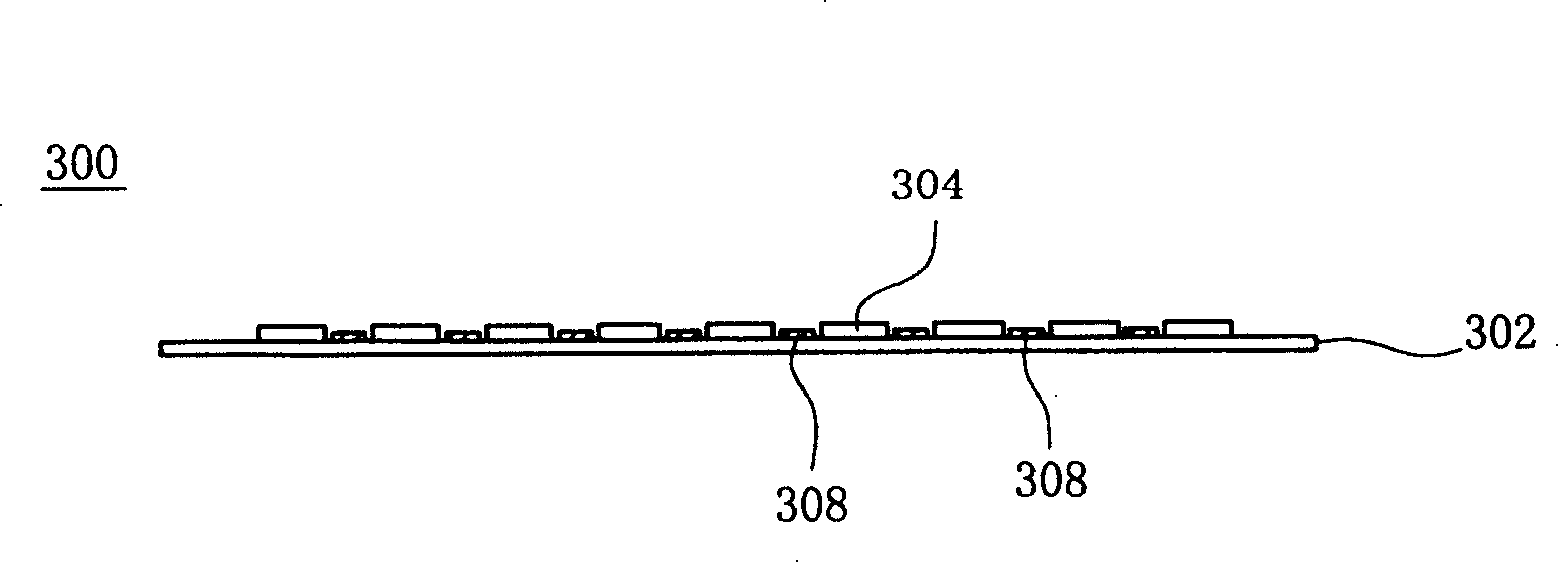

[0024] Without limiting the concept of the present invention and the scope of application, the implementation of the present invention is described below with an embodiment; those of ordinary skill in the art can use it in various applications after understanding the concept of the present invention The temperature-compensated oscillator of the present invention, with the help of the structure of the present invention, can avoid the impact of impurities formed during the bonding process of integrated circuits on the resonant element because it is packaged in a ceramic container at the same time. At the same time, in the structure of the present invention, the integrated circuit is packaged on the printed circuit board without using another ceramic container, so the manufacturing cost can be reduced. Moreover, the structure of the present invention leads the used electrodes out of the structural elements, so that some electrodes with the same signal can be connected together, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com