Tuning-type micro electro-mechanical gyroscope

A micro-electromechanical gyroscope and gyro rotor technology is applied in the direction of rotating gyroscope and gyro effect for speed measurement, measuring device, etc. and other problems, to achieve the effect of heavy weight, simple structure, and stable rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

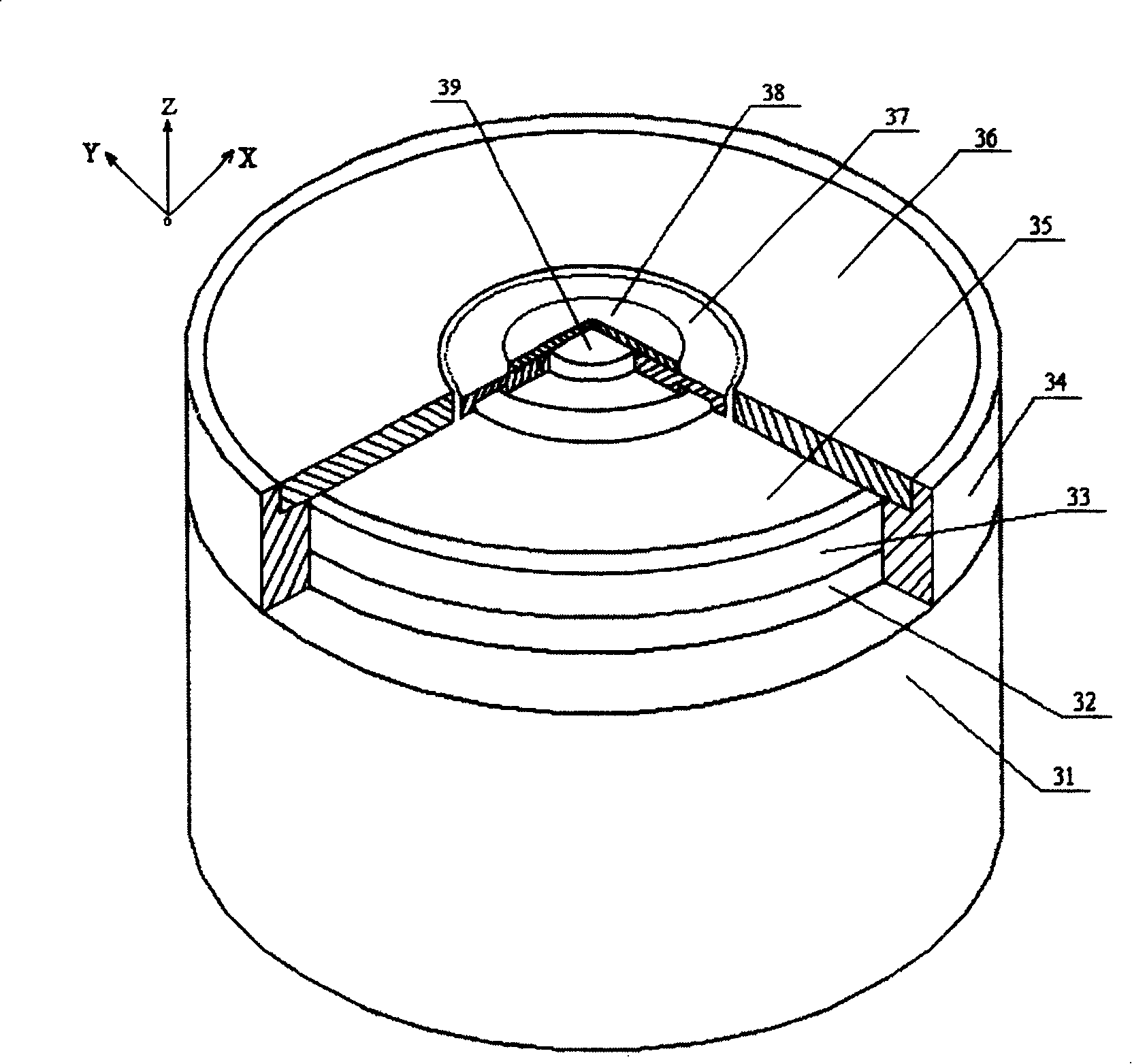

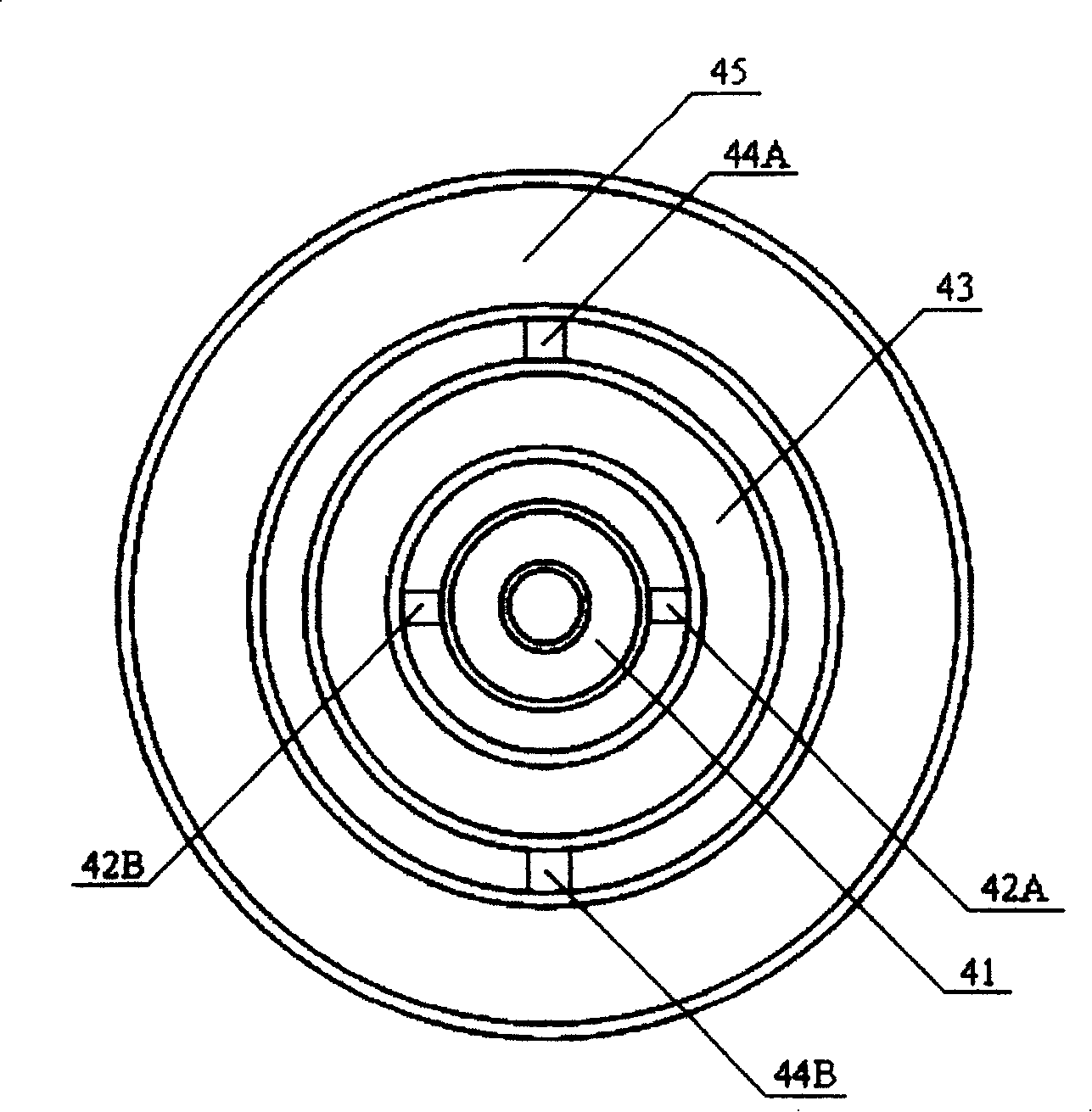

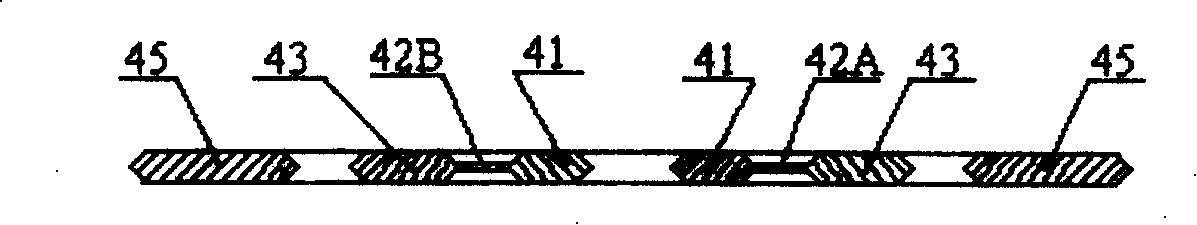

[0023] A tuned micro-electromechanical gyro involving measurement technology, including a motor 31, a gyro rotor / balancing ring 35 is provided on a motor drive shaft 39, and capacitor upper and lower plates are respectively provided above and below the gyro rotor / balancing ring 35 33, 36 and fixed by the fixed ring 34, on the fixed ring 34 is provided with a wire ring 32 for guiding the output signal of the upper and lower plates of the capacitor, and the gyro rotor / balance ring 35 is composed of the inner ring 41, the middle ring 43 and the outer The inner ring 41 is fixedly connected with the drive shaft of the driving motor, the middle ring 43 is a balance ring, and the outer ring 45 is a rotor body. The inner ring and the balance ring are connected by a pair of inner torsion bars 42A, 42B. The balance ring and the rotor The body is connected by a pair of external torsion rods 44A, 44B, and a baffle plate 37 for preventing the rotor from colliding with the capacitor plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com