Method for obtaining high-repetition-frequency large-energy tunable laser

A high-energy, high-repetition technology, used in lasers, laser parts, phonon exciters, etc., can solve the problem of lack of tunable laser high-repetition and high-energy output, and achieve high peak power density, Effects of low average power and short pulse interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

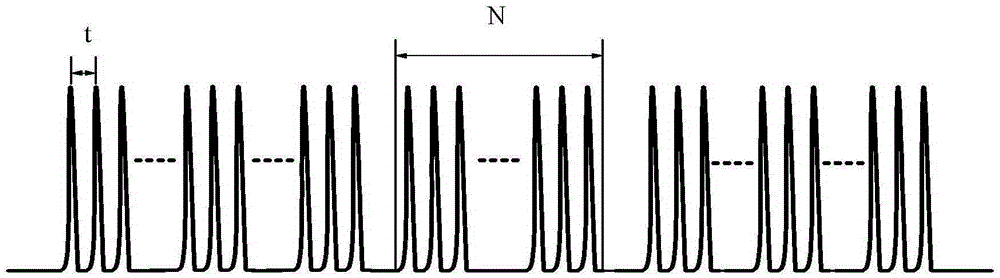

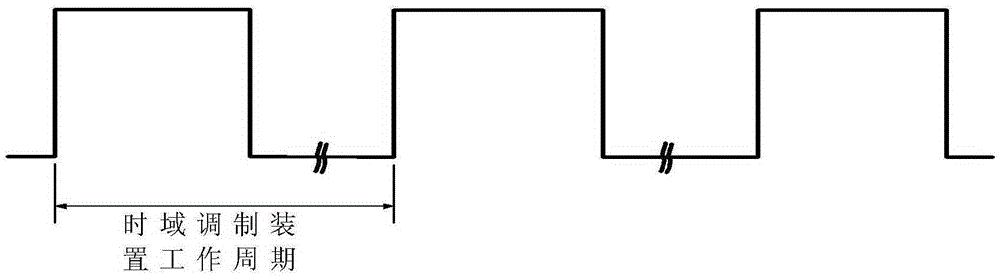

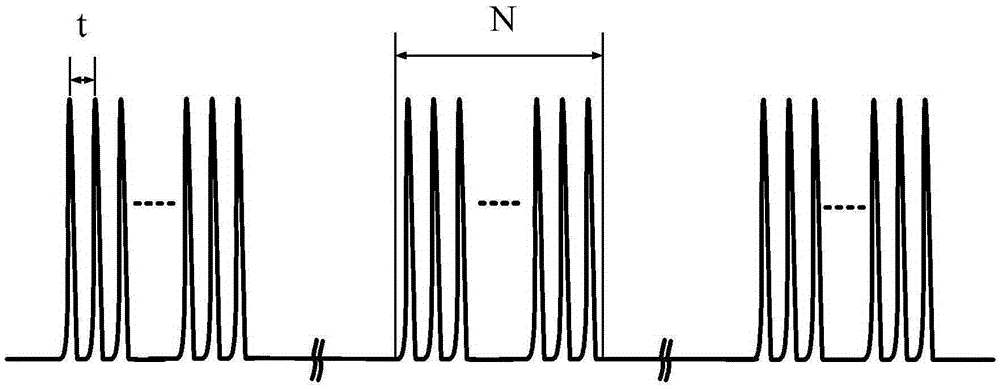

[0013] Specific implementation mode one: refer to Figure 1 to Figure 4 Specifically explain this embodiment, a method for obtaining a high repetition frequency, high energy tunable laser described in this embodiment, the method includes the following steps:

[0014] Step 1: Input the high repetition frequency pump pulse laser into the time domain modulation device 1 for time domain modulation, and output the pump pulse train laser,

[0015] Step 2: After the output pump pulse train laser is shaped by the beam shaping system composed of the concave lens 2 and the convex lens 3, it is incident on the No. 1 reflective prism 4, refracted by the No. 1 reflective prism 4, and then incident to the dye box 5 , the dye solution in the dye box 5 is excited by the pump light pulse laser, and is incident into the resonant cavity formed by the output coupling mirror 6, the grating 10 and the tuning mirror 11, and a beam expander 9 is inserted in the resonant cavity to prevent the intracav...

specific Embodiment approach 2

[0019] Specific embodiment 2: This embodiment is a further description of the method for obtaining high repetition frequency and high energy tunable laser described in specific embodiment 1. In this embodiment, the time domain modulation device adopts electronic shutter or electro-optic crystal The switch is implemented.

specific Embodiment approach 3

[0020] Specific embodiment 3: This embodiment is a further description of the method for obtaining a high-repetition-frequency, high-energy tunable laser as described in the specific embodiment 1. In this embodiment, the tuning mirror 11 is coated with a laser for dye output The high reflection coating and the anti-reflection coating for the pump laser, the reflectivity R>95% of the high reflection coating, and the transmittance T>95% of the anti-reflection coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com