Synthesis method of high purity phosphorus pentachloride

A technology of phosphorus pentachloride and synthesis method, applied in the direction of phosphorus halide/oxyhalide, etc., can solve the problem of low product purity, and achieve the effects of high yield, improved product purity, high theoretical and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

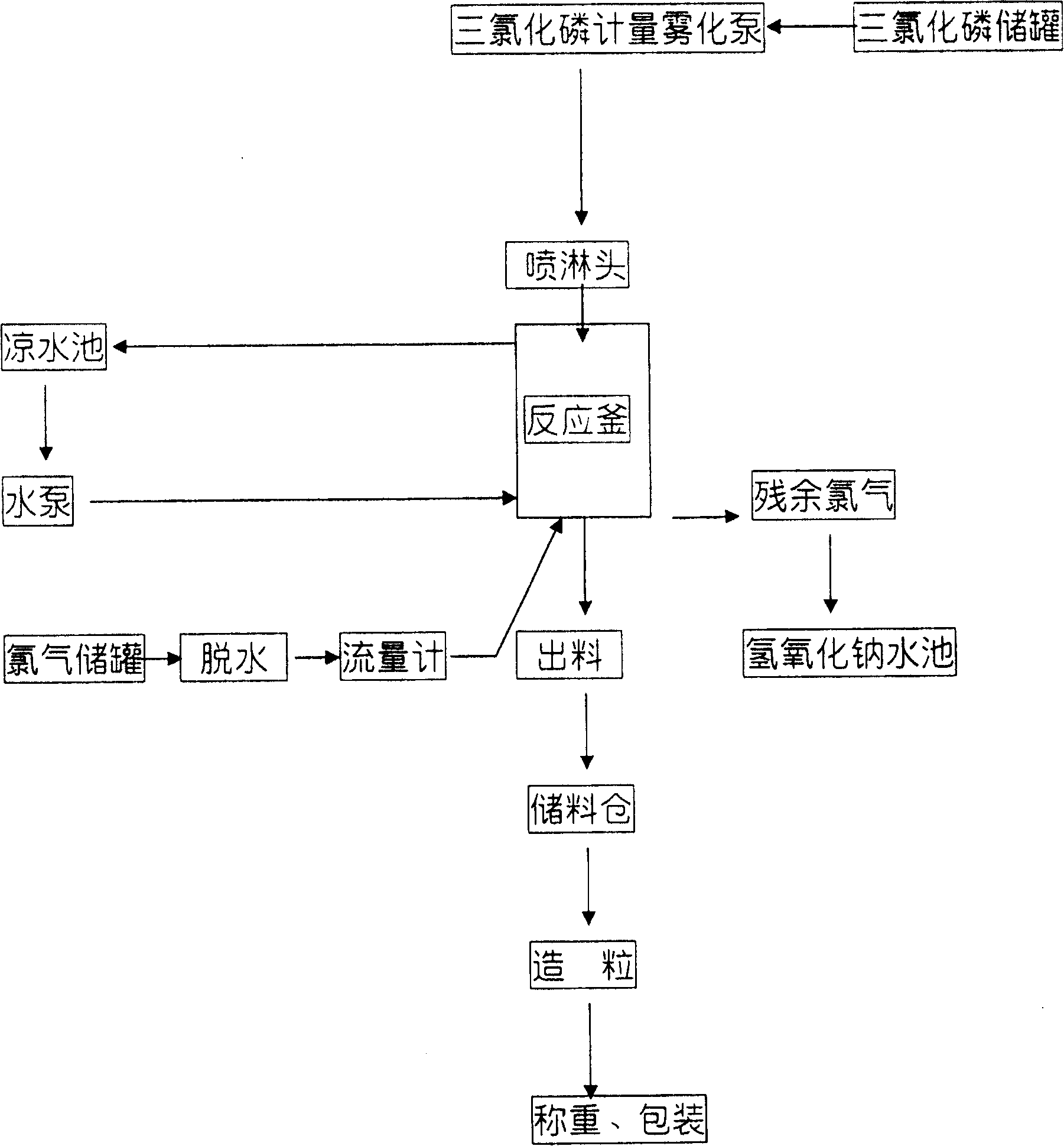

[0014] The invention uses phosphorus trichloride and chlorine gas as raw materials, the mass fraction of phosphorus trichloride is ≥99.99%, the mass fraction of water in chlorine gas is ≤0.0001%, and the chlorine gas is dried with concentrated sulfuric acid+anhydrous magnesium sulfate. Phosphorus trichloride and chlorine are fed in an equimolar 1:1 manner, Cl 2 Entered from the bottom of the reactor, PCl 3 Spray down from the top of the reactor in mist form, the feeding time is about 0.3h, the feeding rate of phosphorus trichloride is 60-70kg / h, and the circulating water is turned on at the same time, the reaction temperature is controlled at 110-130°C, PCl 3 After contacting with chlorine gas, it reacts rapidly to generate phosphorus pentachloride, and releases the reaction heat, the phosphorus trichloride mist is vaporized, and the reaction is carried out by gas-gas convection, and the solid phosphorus pentachloride condenses on the inner wall of the reactor. The synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com