Medium and low perssure fine water mist spray nozzle having porous liquid film jet mist throwing disk

A water mist nozzle and jet technology, which is used in spray devices, spray devices, fire rescue and other directions, can solve the problems of small spray impulse, short range, insufficient spray volume, etc., to save investment, reduce water pollution, and apply wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

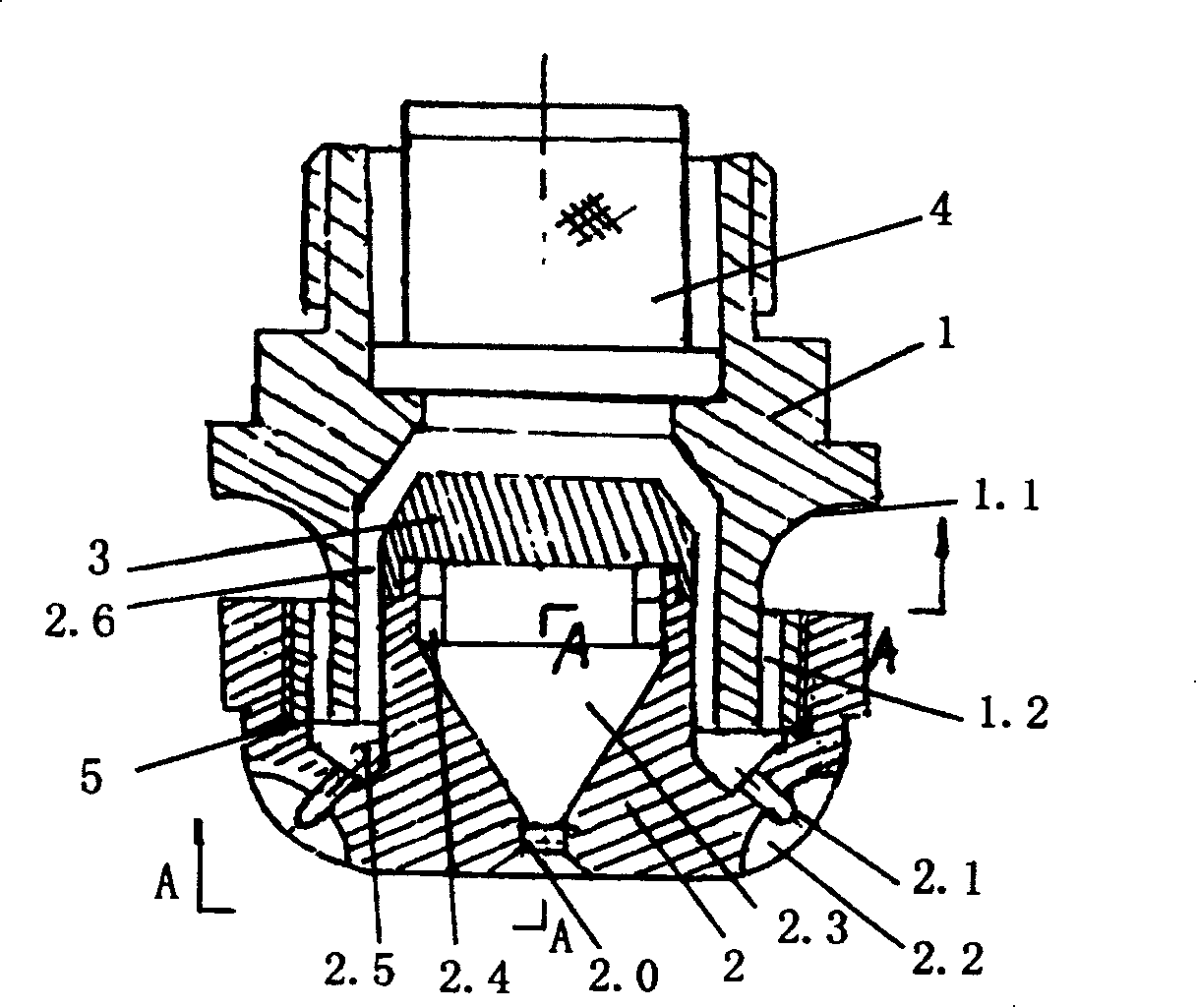

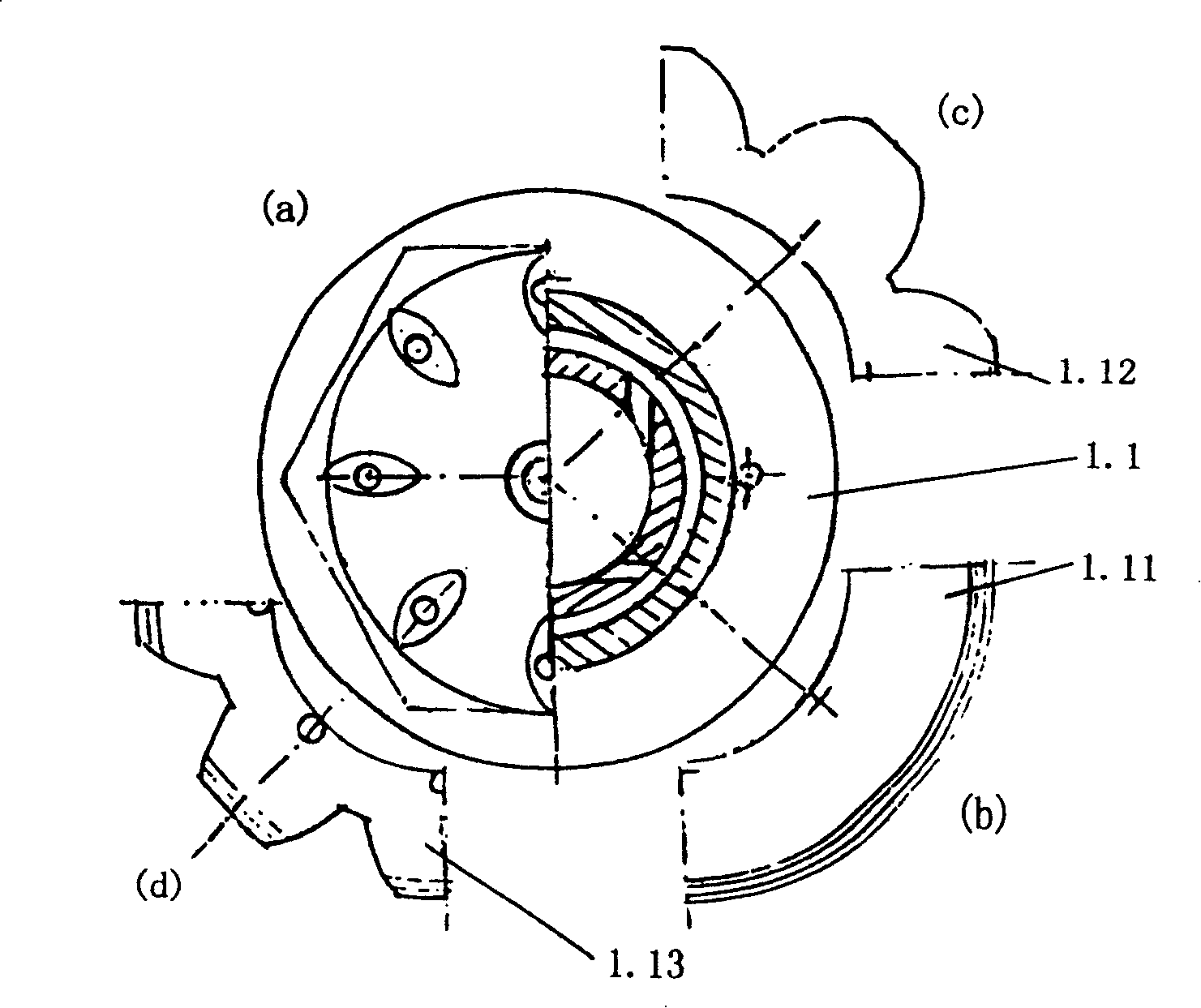

[0068] see figure 1 , 2, Embodiment 1 is a fine water mist nozzle using a porous liquid film jet band annular throwing mist disc and eye-shaped hole and swirl chamber. A filter 4 is installed at the central hole inlet of the shower head seat 1. The swirl chamber 2.3 on the nozzle body 2 and the main nozzle 2.0 of the swirl chamber are arranged in the central cavity of the nozzle seat, and 2 to 4 tangential grooves or tangential holes 2.4 are arranged on the wall of the swirl chamber, and the tangential grooves or tangential holes The outer generatrix of the hole is tangent to the circumference of the big end hole of the swirl chamber. A stuffy cover 3 is provided on the top of the swirl chamber. The nozzle body 2 is screwed on the outer fine lines of the nozzle seat with an internal thread and sealed with a sealing ring 5 . On the nozzle body 2, an annular groove 2.5 facing the end plane of the nozzle seat is provided. The inlet of the annular groove 2.5 communicates with t...

Embodiment 2

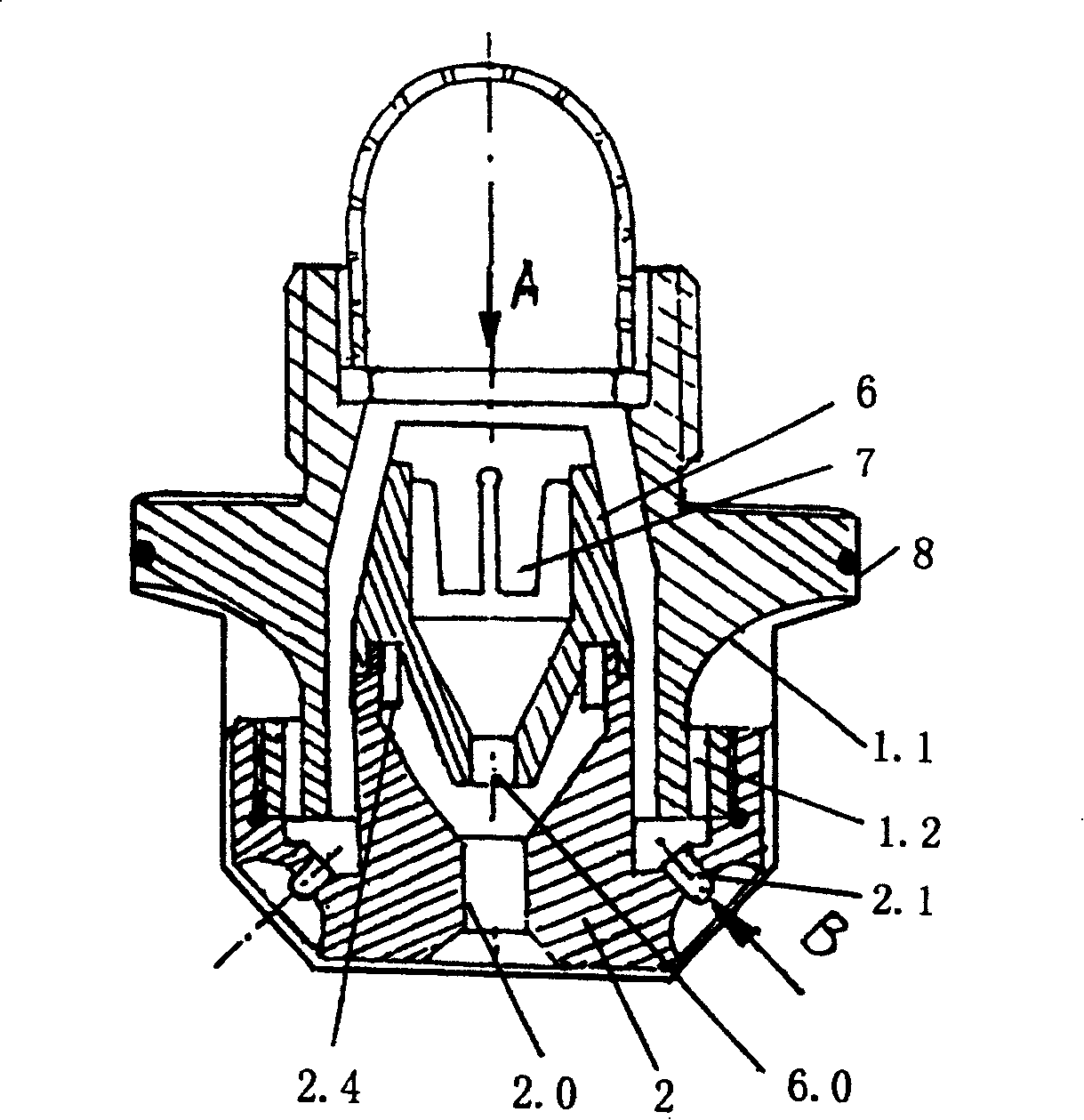

[0070] see Figure 3-11 , Embodiment 2 is a fine water mist nozzle with an annular throwing disc and a central jet chamber. This example image 3 The main structure shown is basically the same as that of Embodiment 1, in image 3 The ring-shaped mist throwing disc 1.1, film jet hole 1.2, nozzle body 2, eye-shaped hole 2.1 and figure 1 Same, plus the eye slots are also the same as the figure 1 The eye-shaped hole slot 2.2 in is the same, and the same part will not be described again. The difference is the stuffy cover 3 among the embodiment 1 (referring to figure 1 ) is replaced by the central jet chamber 6 and its inner mechanism or similar mechanism in the second embodiment. The central jet hole 6.0 is coaxially opposite to the main nozzle 2.0 of the swirl chamber of the nozzle body. The present embodiment sprinkler head is provided with the dustproof cover 8 that machine sheet or metal foil etc. are made, and the dustproof cover is loosely sleeved around the sprinkler ...

Embodiment 3

[0072] see Figure 12-14 , the present embodiment is a combined atomized fine water mist nozzle with a ring-shaped mist throwing disc that can be opened and sprayed at a constant pressure. Its structure is the same as the main body of embodiment 2 image 3 The structures are basically the same, and the same parts will not be described again. The difference is that two circles of eye-shaped holes are set on the nozzle body, and the second difference is that there are 2 to 4 pre-stage tangential swirls on the top surface of the central jet chamber 9 of the combined atomized fine water mist nozzle. Groove 9.1, central jet chamber cylindrical hole built-in constant pressure spring 10, constant pressure spring 10 supports the sealing disc 11 with small tail post. When there is no pressure or the pressure is very low, the sealing disc seals the entrance of the central hole of the nozzle seat, and the nozzle does not spray. When a certain pressure is reached, the sealing disc retre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com