Optical fiber cutting apparatus

A technology of cutters and fibers, applied in the directions of instruments, light guides, optics, etc., can solve the trouble of properly storing various gaskets, the time-consuming cutters, etc., and achieve satisfactory reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below with reference to the accompanying drawings. The drawings are provided for the purpose of explanation only and do not limit the scope of the invention. The same symbols denote the same parts in the drawings to avoid repeated explanations. The dimensional ratios in the drawings are not always accurate.

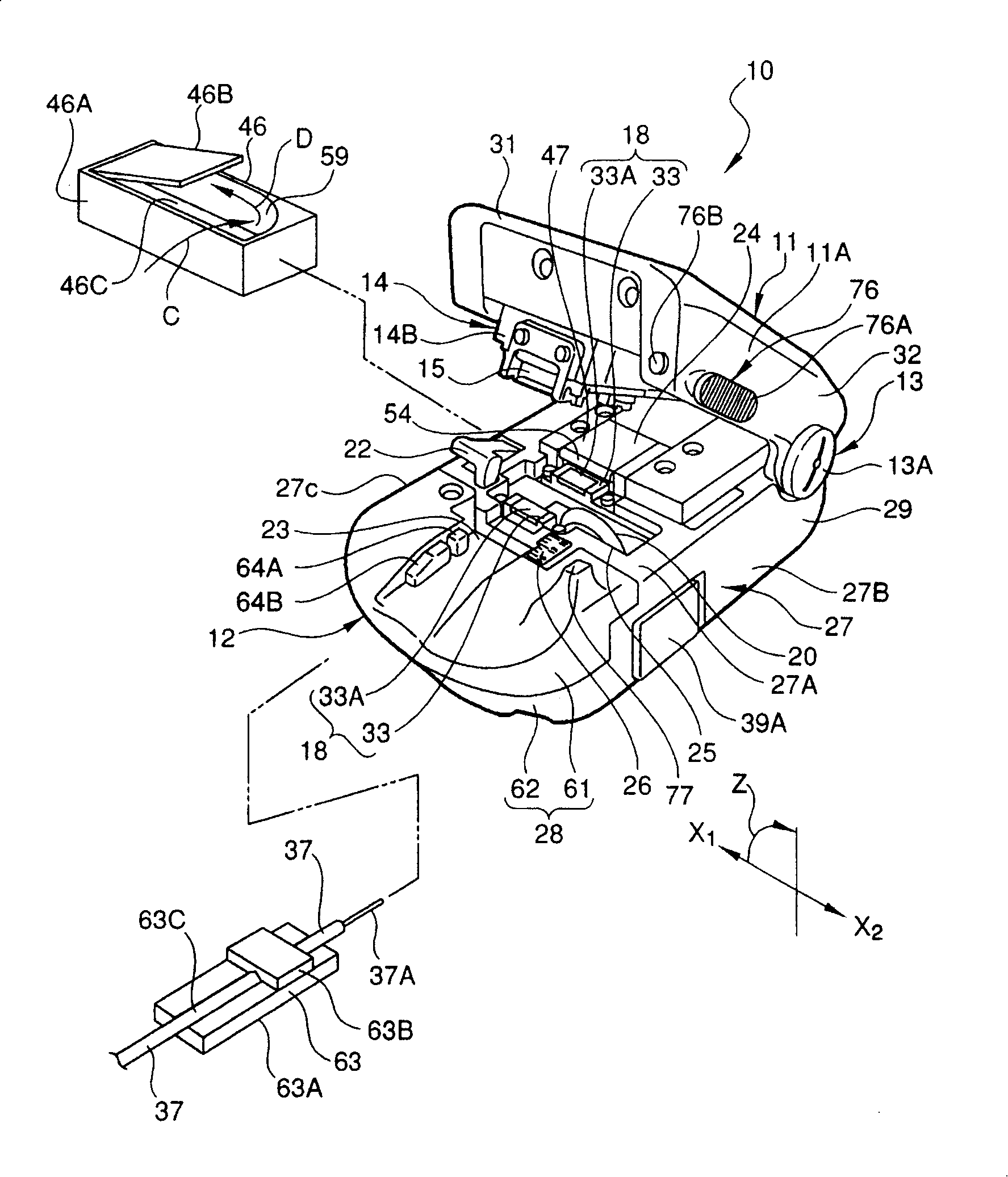

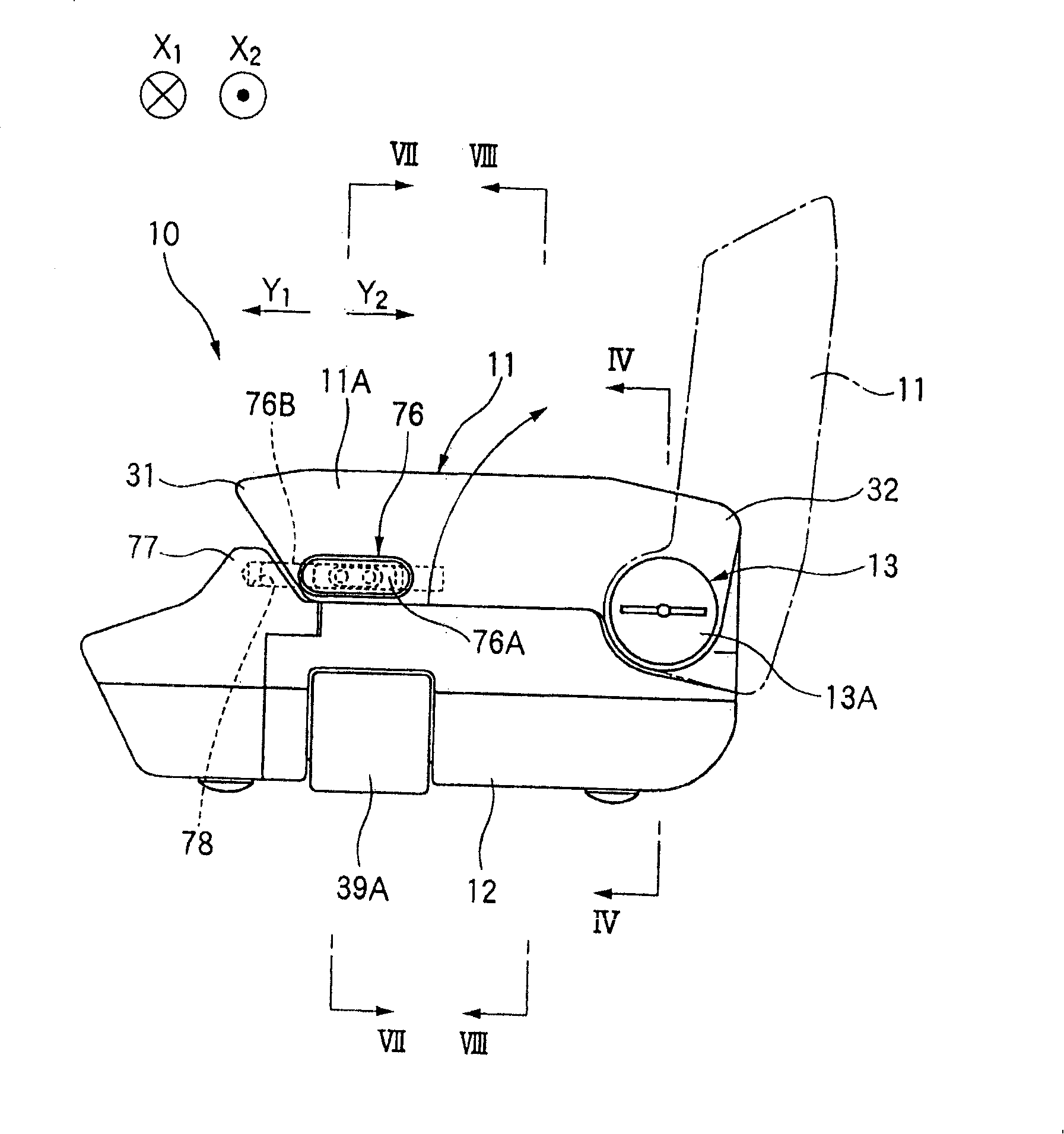

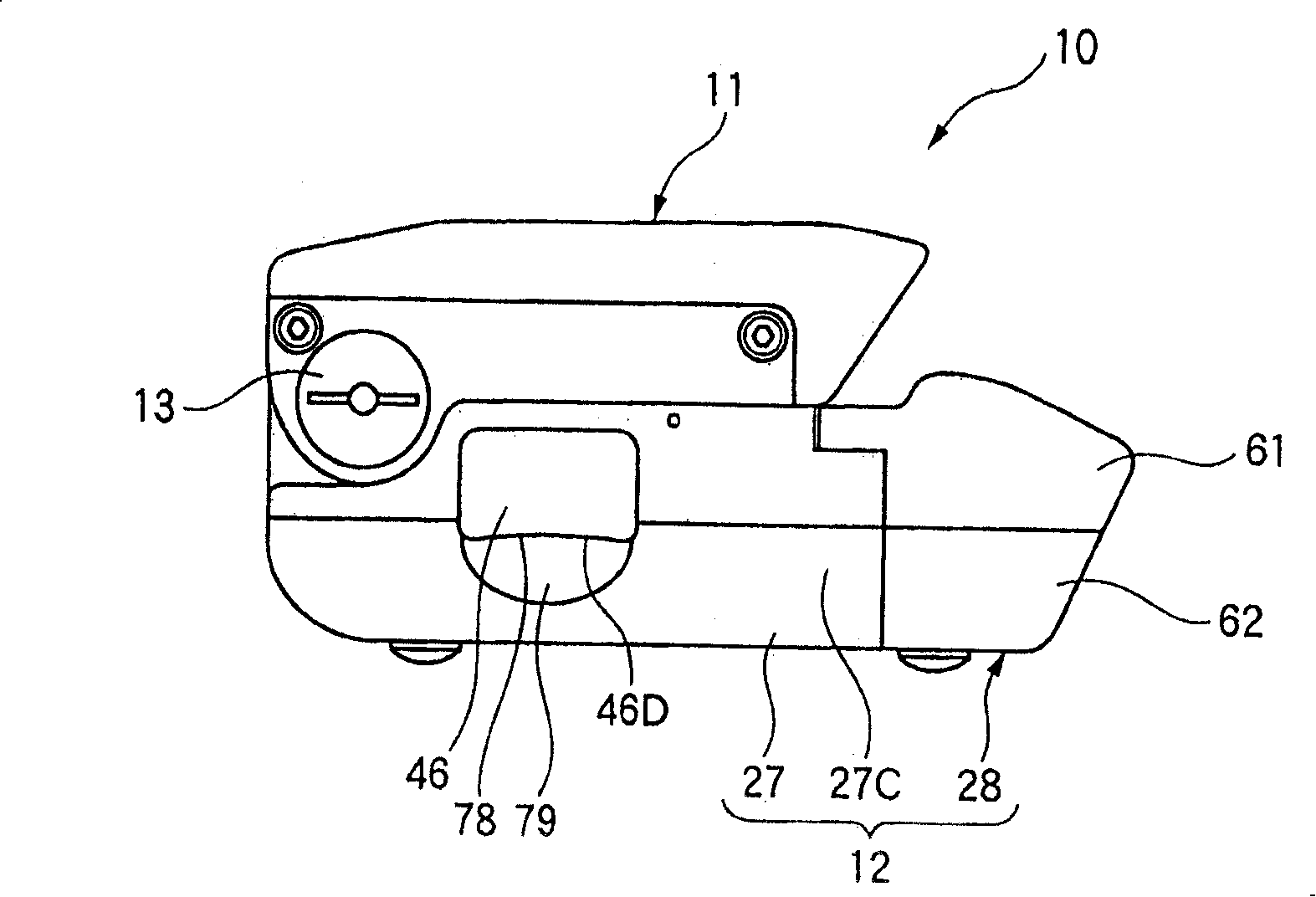

[0044] figure 1 is a perspective view of a fiber cutter and a holder to be mounted thereon according to a first embodiment of the present invention. figure 2 , 3 , and 4 are a right side view, a left side view, and a rear view, respectively, of the fiber cutter according to the first embodiment of the present invention. 5 is a sectional view of the fiber cutter according to the first embodiment of the present invention, and shows a state in which upper and lower housings are opened. Fig. 6 is a view similar to Fig. 5, and shows a state in which upper and lower cases are closed. 7, 8, and 9 are cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com