Microelectronic substrate with integrated devices and its manufacturing method

A technology of microelectronics, microelectronic devices, applied in the field of manufactured devices, which can solve the problems of increasing component size, speed and performance degradation, long conductive traces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

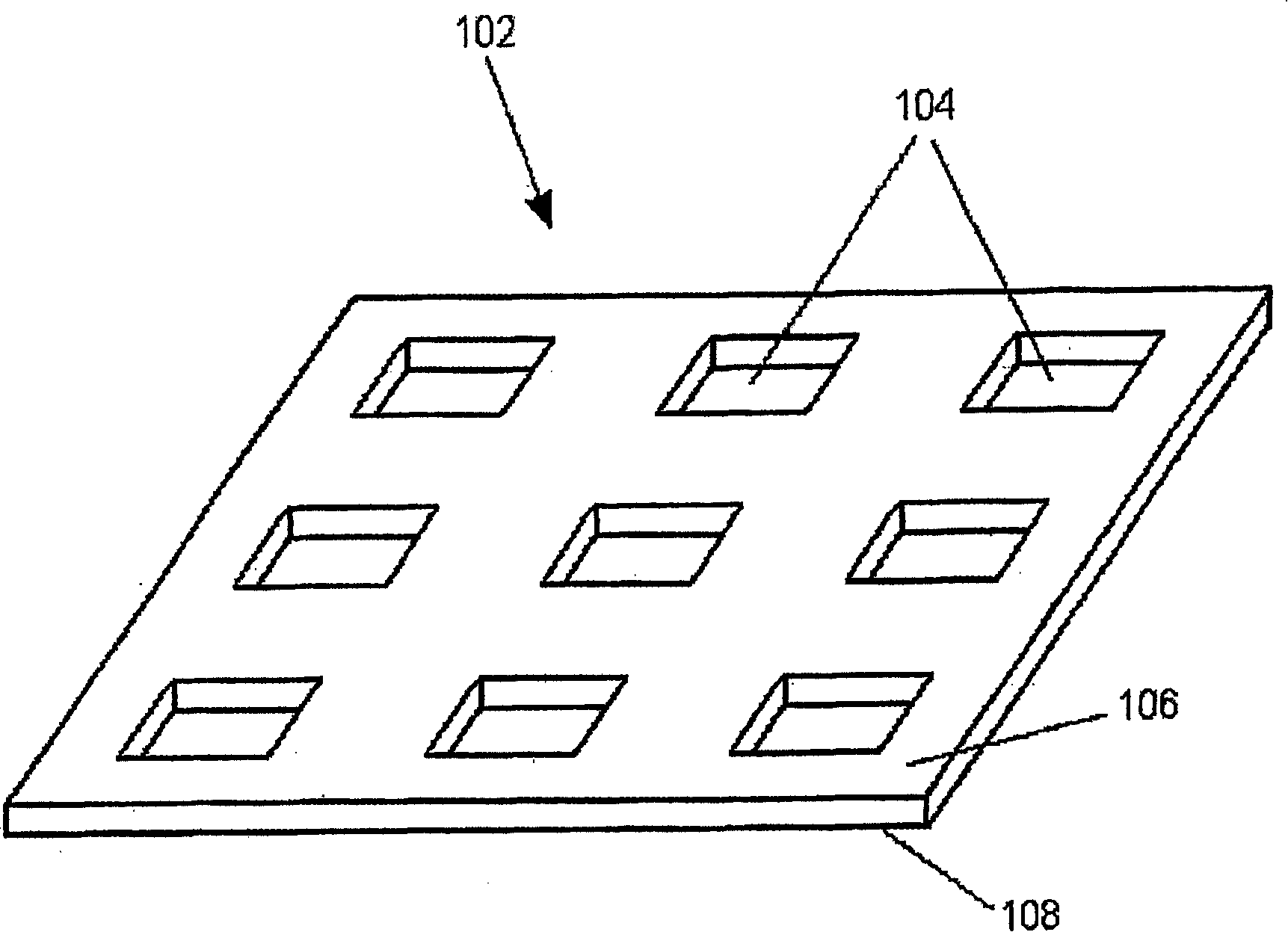

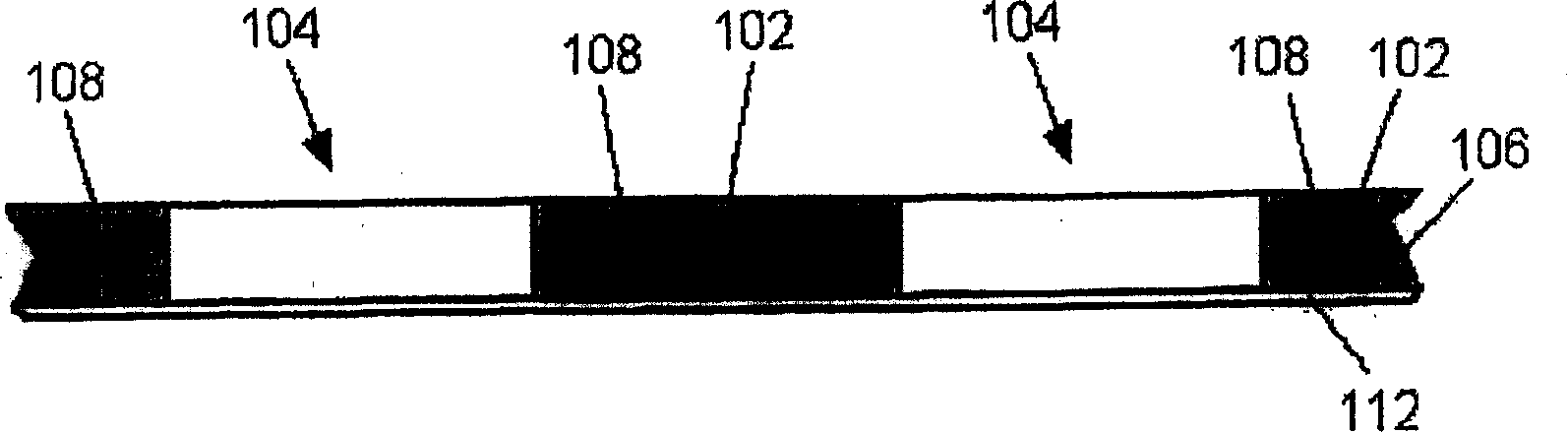

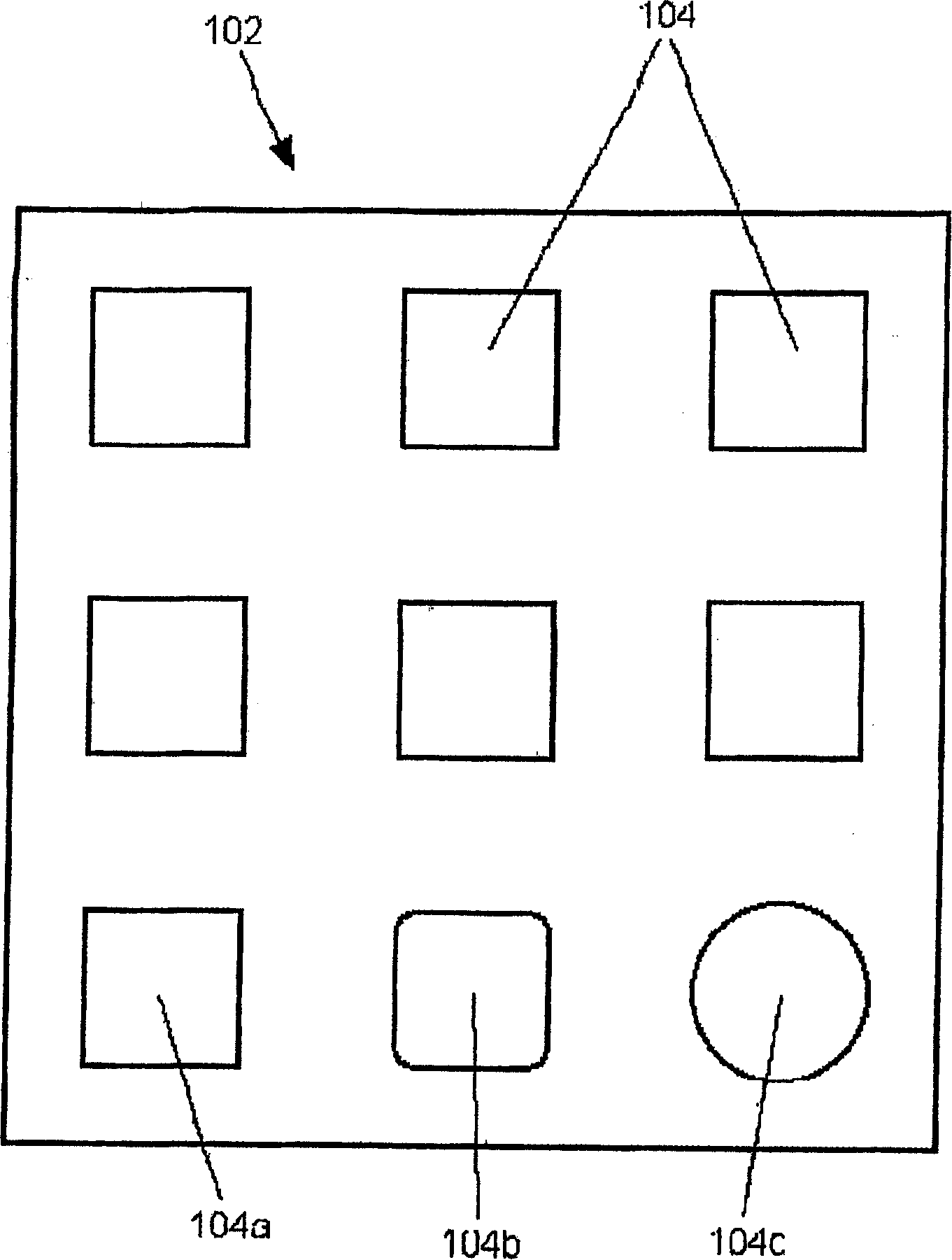

[0025] Although Figures 1 to 19 Various views of the present invention are shown, however these figures are not meant to represent a precise and detailed depiction of the microelectronic assembly. Rather, the figures merely show microelectronic assemblies in a manner that more clearly conveys the concepts of the invention. In addition, elements common to these figures are denoted by the same reference numerals.

[0026] The present invention includes a substrate fabrication technique that places at least one microelectronic die within at least one opening of a microelectronic substrate core and secures the microelectronic die within said opening with an encapsulant, or at least one The microelectronic die is encapsulated within the encapsulant without the core of the microelectronic substrate. An interconnect layer of dielectric material and conductive traces is then fabricated over the microelectronic die, encapsulation material, and microelectronic substrate core (if any)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com