Reverse buckling equipment

An undercut and anchor technology, used in drilling equipment and methods, rotary drilling rigs, wellbore/well components, etc. The problems such as deceleration of the drill pipe are reduced to achieve the effect of improving the success rate, reducing the workover cost and increasing the torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

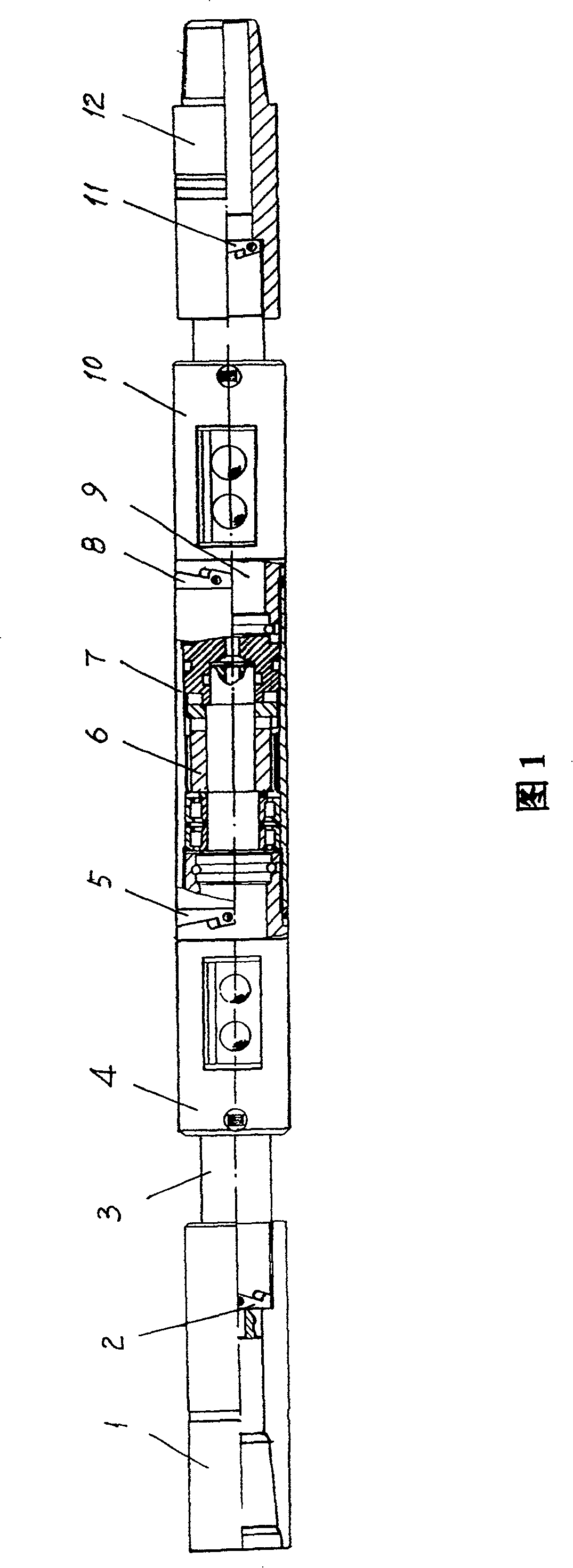

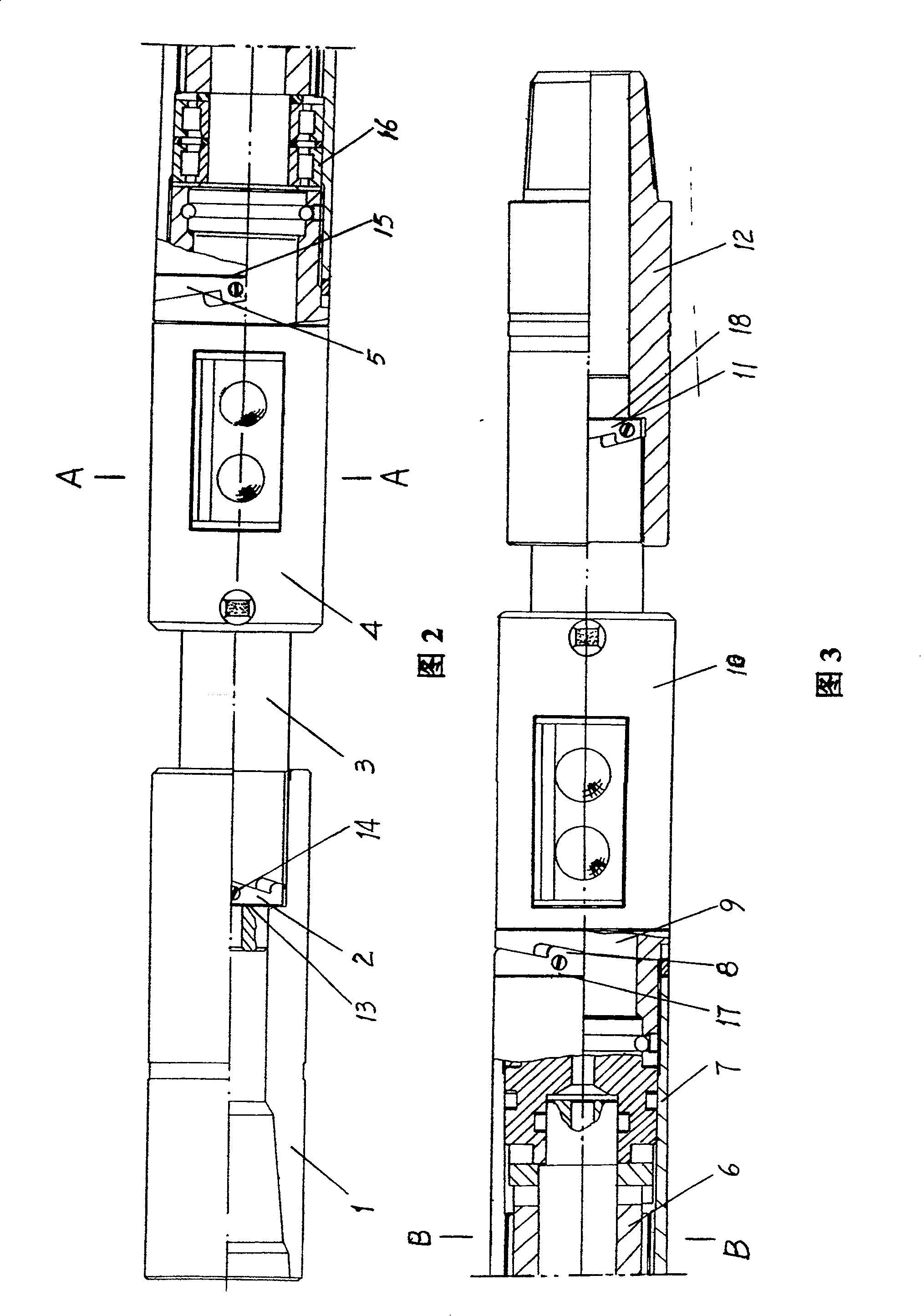

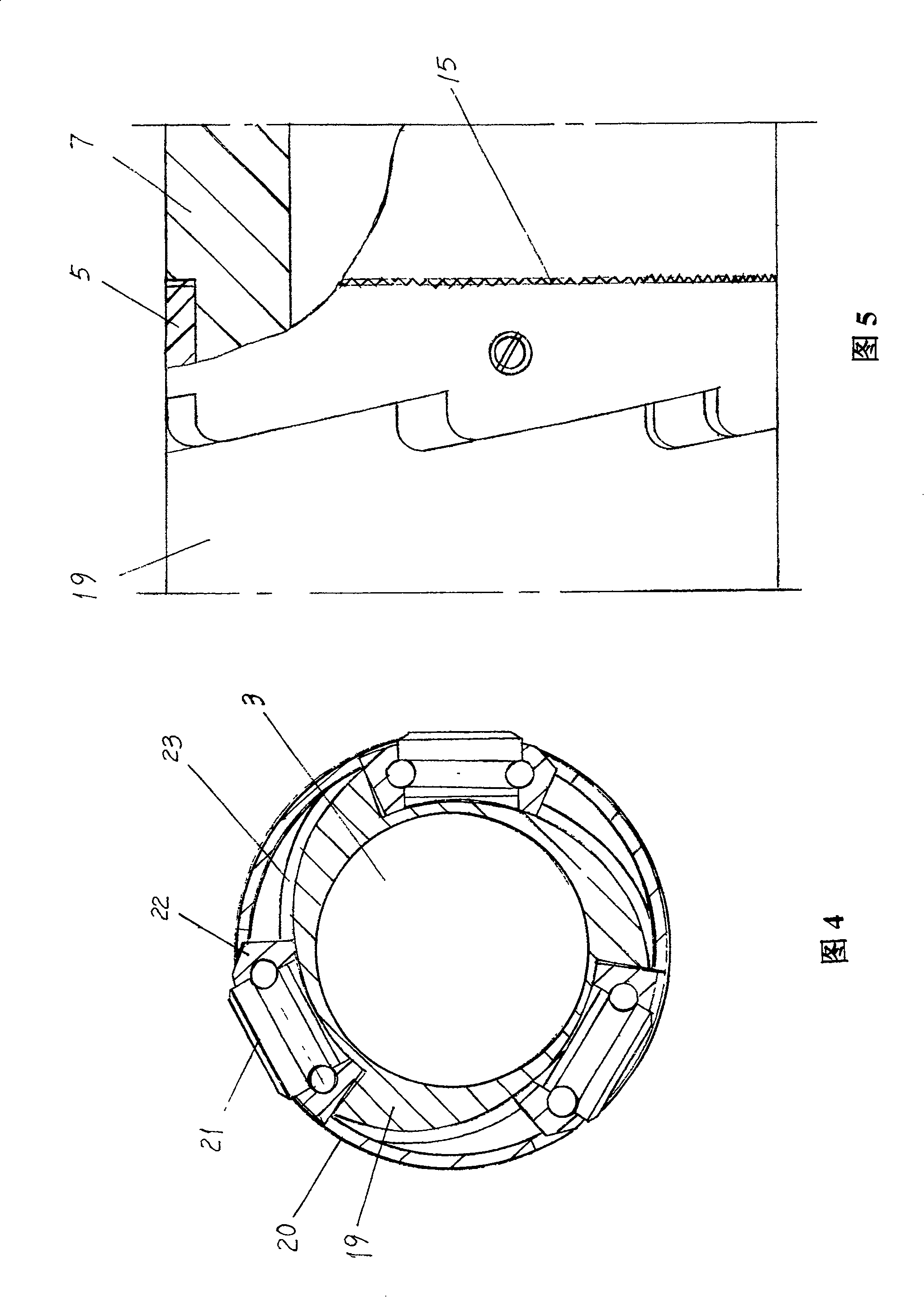

[0013] See Figures 1-6, the specific structure of the present invention is as follows: the lower part of the upper joint 1 is threadedly connected to the eccentric shaft 3, and the torsion increasing ring 2 is assembled between the lower part of the upper joint 1 and the upper end of the eccentric shaft 3, and the torsion increasing ring 2 and the eccentric shaft 3 A plurality of evenly distributed slope-shaped slides are arranged on the corresponding circumferential end surfaces that are in contact with each other. The slope-shaped slides of the torsion increasing ring 2 and the slope-shaped slides of the eccentric shaft 3 are in opposite directions and bonded together. Engaging end surface teeth 13 are provided on the corresponding circumferential end faces of the torque increasing ring 2 and the lower part of the upper joint 1 in contact with each other; limit screws 14 are assembled on the torque increasing ring 2 . Assemble upper anchor 4 on eccentric shaft 3, the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com