Guide rib for reinforcing internal cycle for smoke purifying reaction tower

A flue gas purification and reaction tower technology, which is applied in the field of flue gas pollution purification equipment and diversion fins, can solve the problem of high-concentration wall backflow without proper flow stabilization measures, unable to form a stable and efficient internal circulation, and affecting the desulfurization process Mixing effect and other issues, to achieve the effect of reducing the carrying of solid particles, reducing interference and carrying, and good gas-solid mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

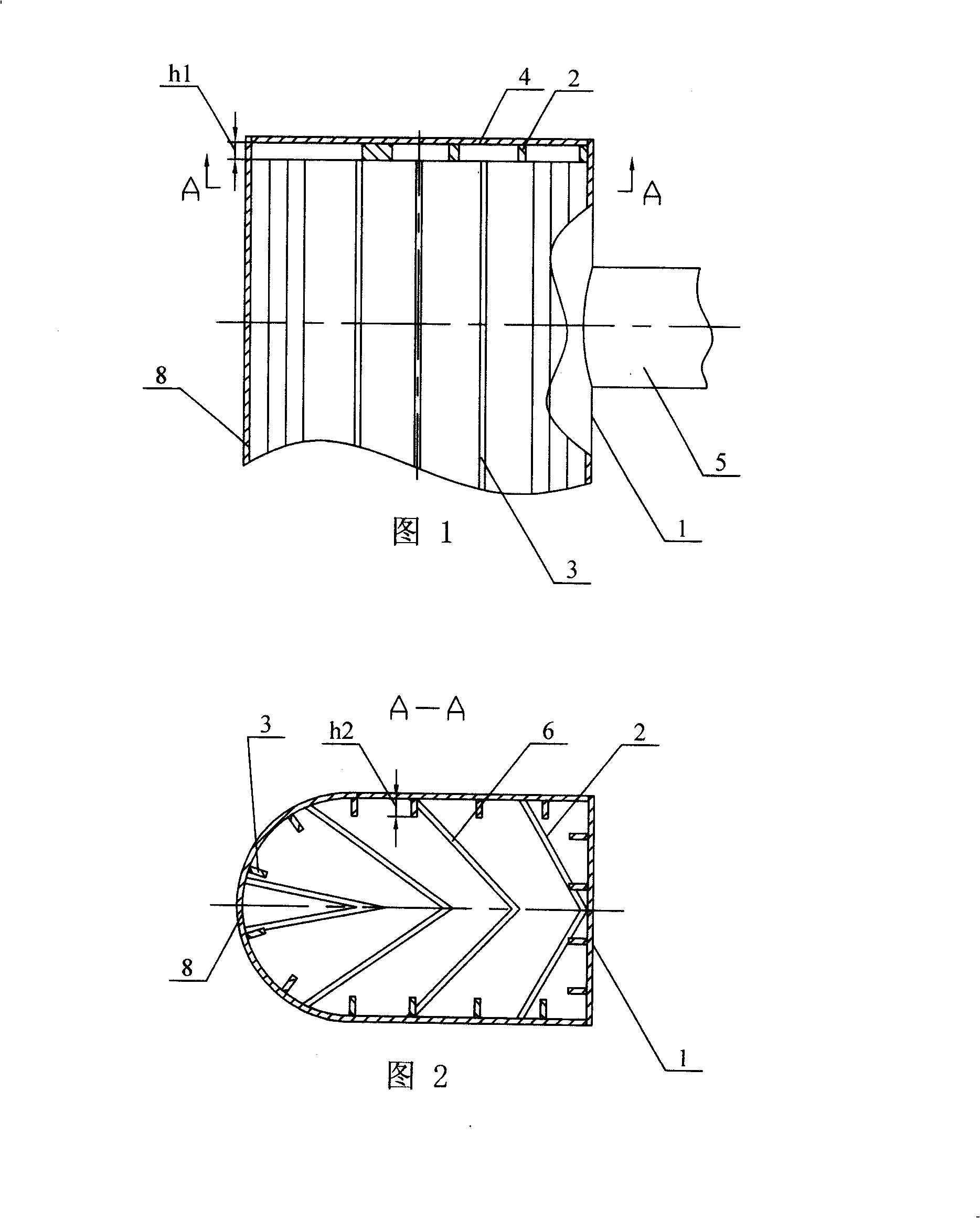

[0009] Specific Embodiment 1: This embodiment is described in conjunction with Fig. 1 and Fig. 2. In this embodiment, the tower top ribs 2 fixed on the top end surface 4 in the tower top 1 and the fins evenly distributed on the inner side wall 8 of the tower top 1 The side wall fins 3 are composed; the tower top fins 2 are a group of bent fins 6 with openings facing the opposite side of the airflow outlet 5 and gradually expanding along the direction of the airflow outlet 5. The tower top 1 The cross section is a combination of rectangle and semicircle, the distance h1 between the lower end surface of the tower top fin 2 and the top end surface 4 inside the tower top 1 is 20-200 mm, and the outer surface of the side wall fin 3 The distance h2 between the end surface and the inner wall 8 of the tower top 1 is 20-200 mm, and the tower top fins 2 and side wall fins 3 are made of metal materials or cast concrete. Such setting can enhance the flow guiding effect of the fins.

specific Embodiment approach 2

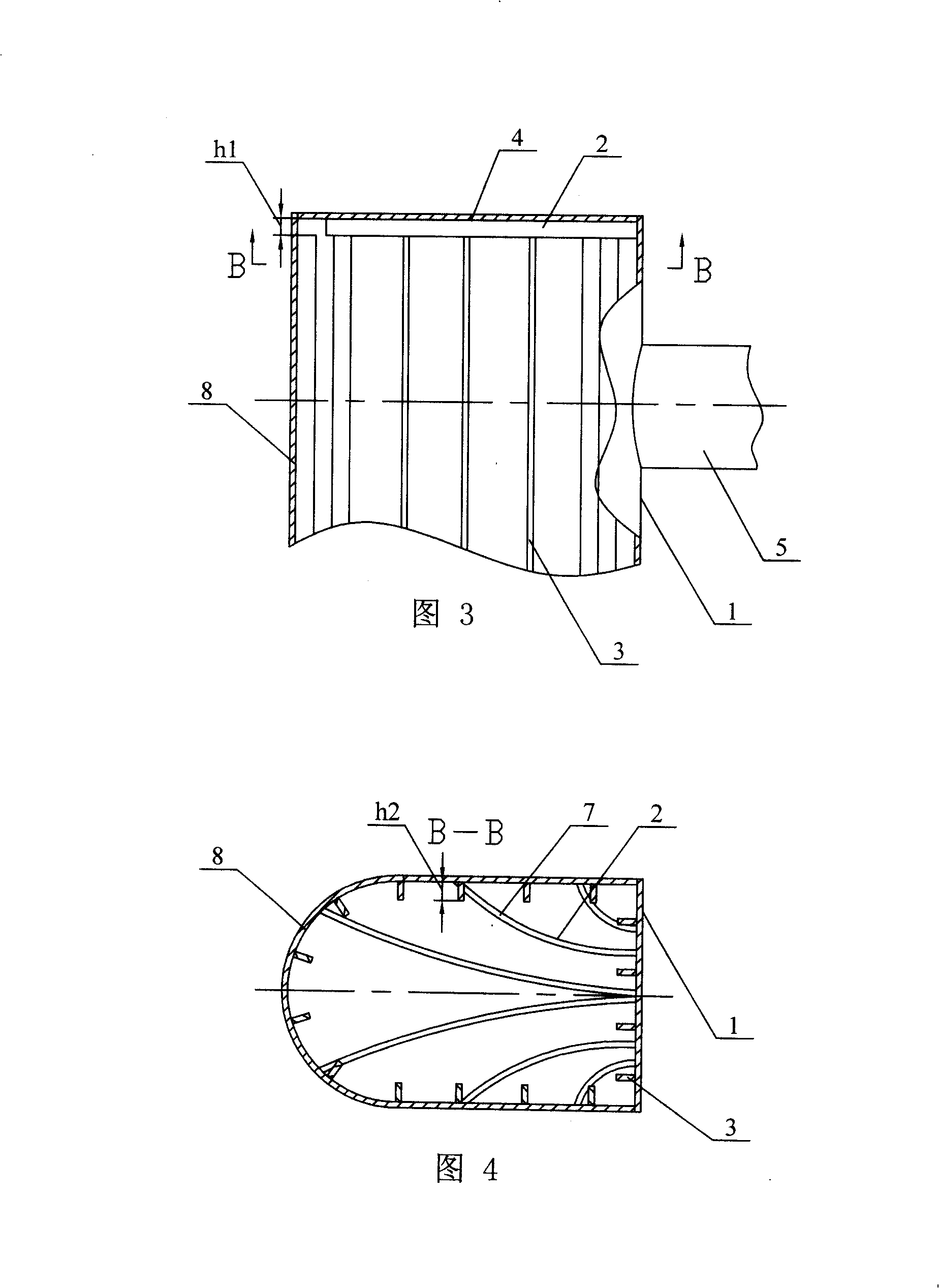

[0010] Specific embodiment 2: This embodiment is described in conjunction with Fig. 3 and Fig. 4 , the difference between this embodiment and specific embodiment 1 is: the tower top fins 2 of this embodiment are a group of openings facing the opposite side of the airflow outlet 5 , and the curved fins 7 gradually expand along the direction of the airflow outlet 5 . Such setting can enhance the flow guiding effect of the fins.

specific Embodiment approach 3

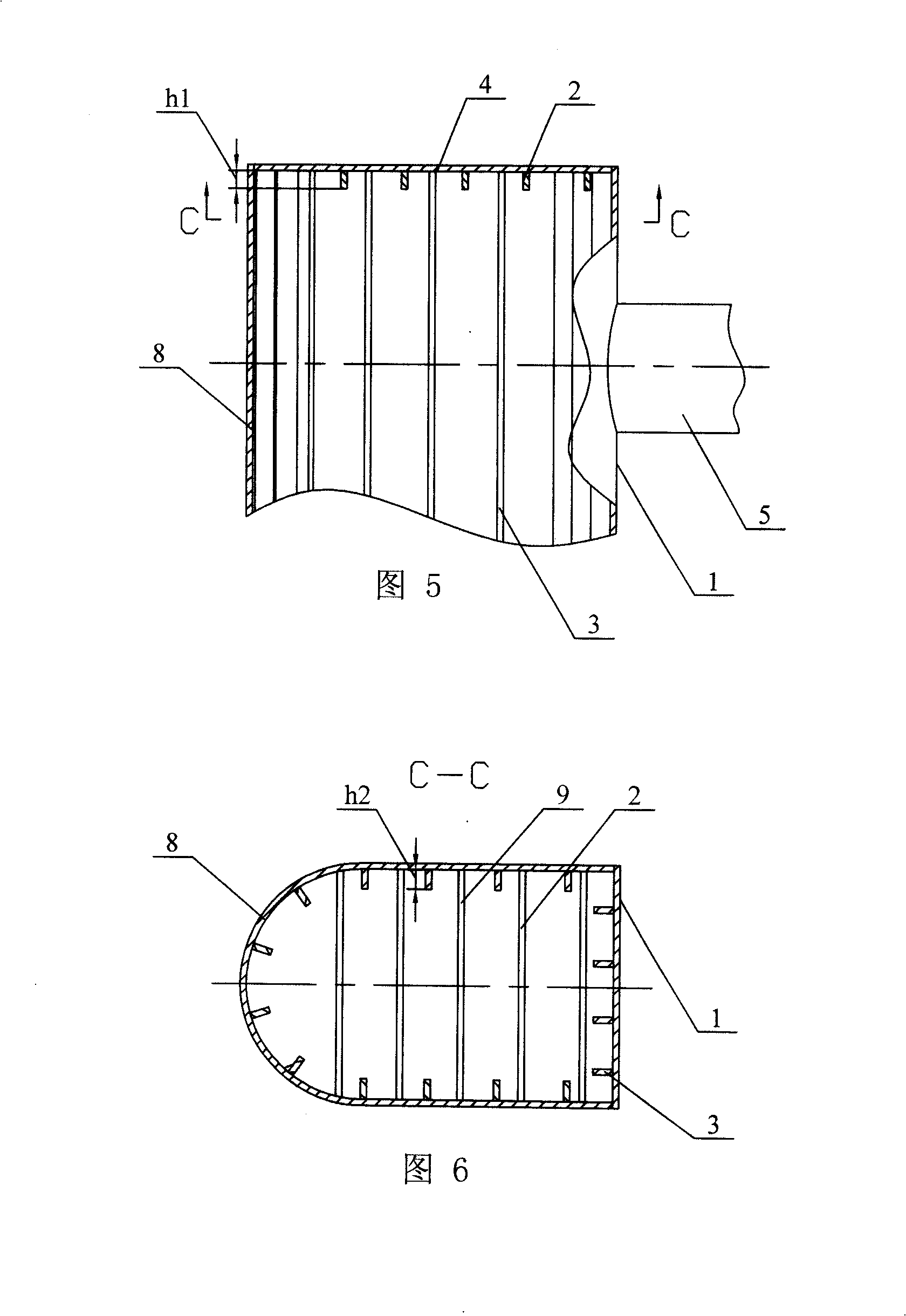

[0011] Specific embodiment 3: This embodiment is described in conjunction with Fig. 5 and Fig. 6. The difference between this embodiment and specific embodiments 1 and 2 is that the tower top fins 2 of this embodiment are a group along the top of the tower top 1 The straight ribs 9 uniformly distributed laterally on the surface 4. Such setting can enhance the flow guiding effect of the fins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com