Control device of brushless D.C. motor for fully-automatic washing machine and control method thereof

A fully automatic washing machine and brushing DC motor technology, applied in washing devices, other washing machines, mechanical equipment, etc., can solve the problems of heavy load and damage to the serrated protrusions, and improve reliability and internal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

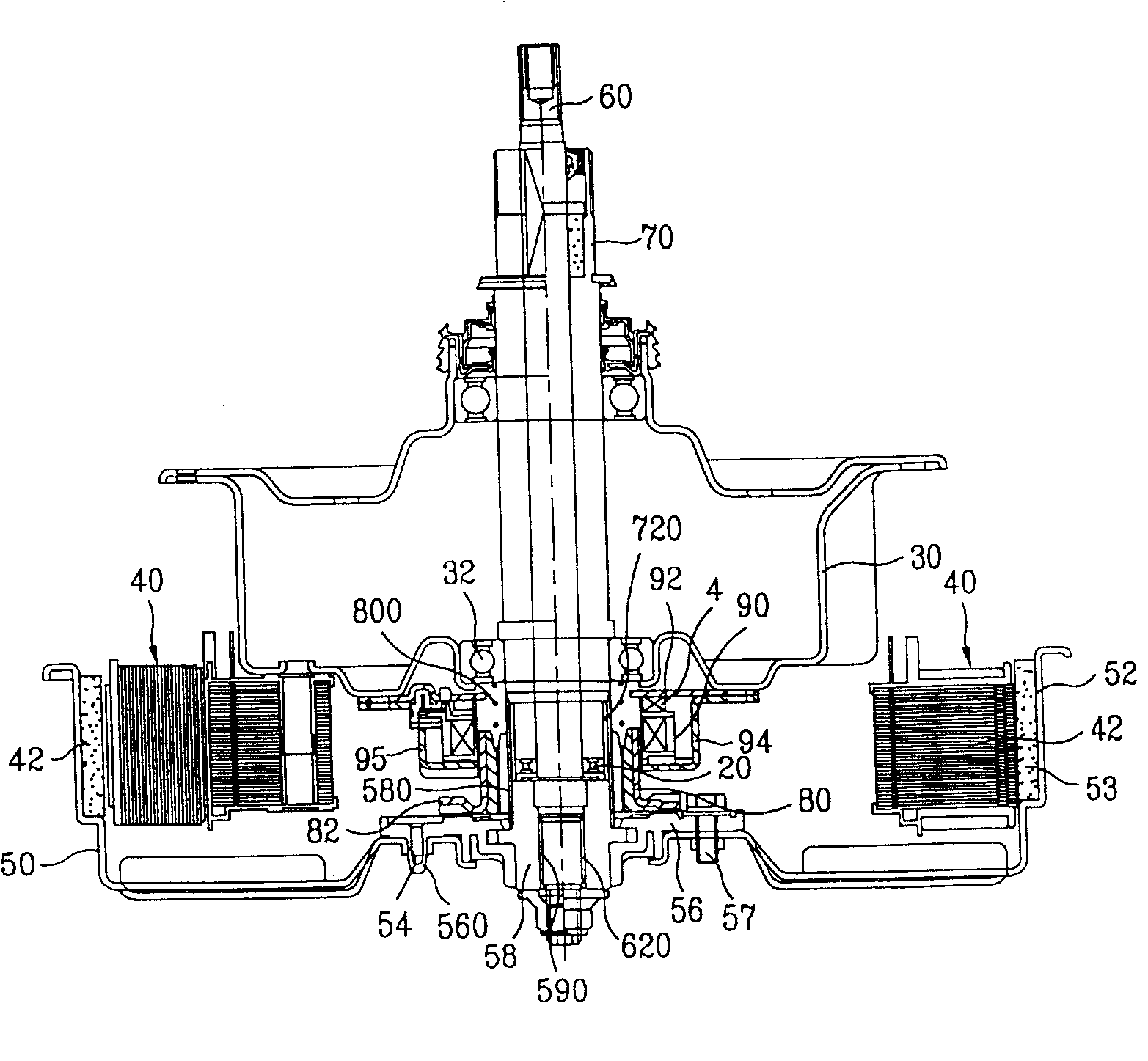

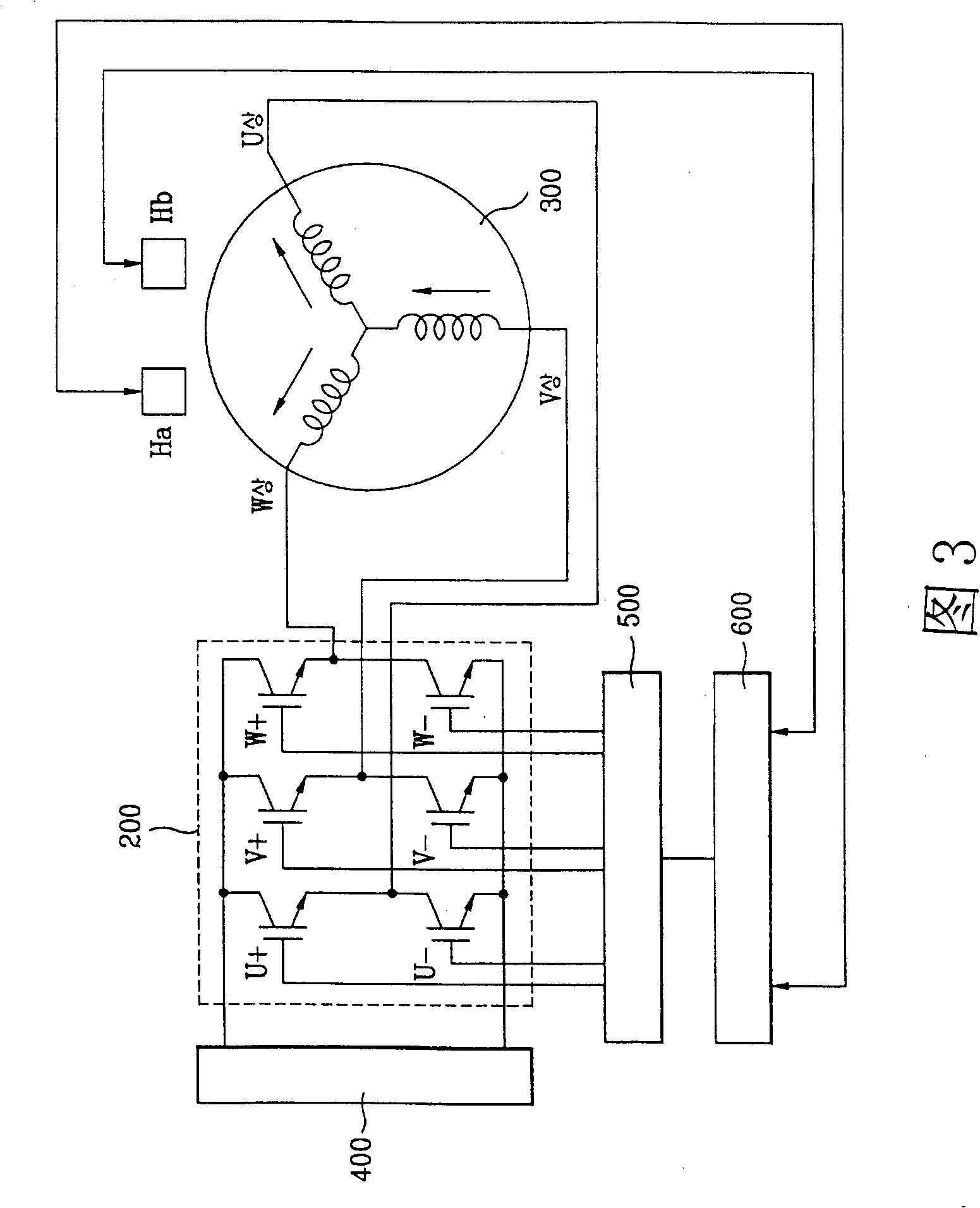

[0064] Refer to the attached Figure 6 , the embodiments of the present invention will be described in detail.

[0065] Figure 6 It is the circuit structure diagram of the present invention, showing the drive circuit structure diagram of the Hall sensor and the cylindrical coil controlled by the thermoelectric protector.

[0066] Such as Figure 6 As shown, the fully automatic washing machine includes the following structures: a brushless DC motor, a washing shaft 60 , a dehydration shaft 70 , and a movable connector 80 . The above-mentioned brushless DC motor is composed of a stator 40 and a rotor 50; the above-mentioned washing shaft 60 is combined on the rotor 50 of the above-mentioned motor, and rotates together with the above-mentioned rotor 50 when the above-mentioned rotor 50 rotates; the above-mentioned dehydration shaft 70 is arranged on the outside of the above-mentioned washing shaft 60; The movable coupling 80 moves up and down along the dehydration shaft 70 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com