Slagoff method and device for solution storage trough containing suspended matter

A technology containing aqueous solution and solid suspended matter, which is applied to the feeding/discharging device, packaging, transportation and packaging of the settling tank, which can solve the problems of long time, large investment and difficult slag discharge, so as to improve the utilization rate, Solve the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

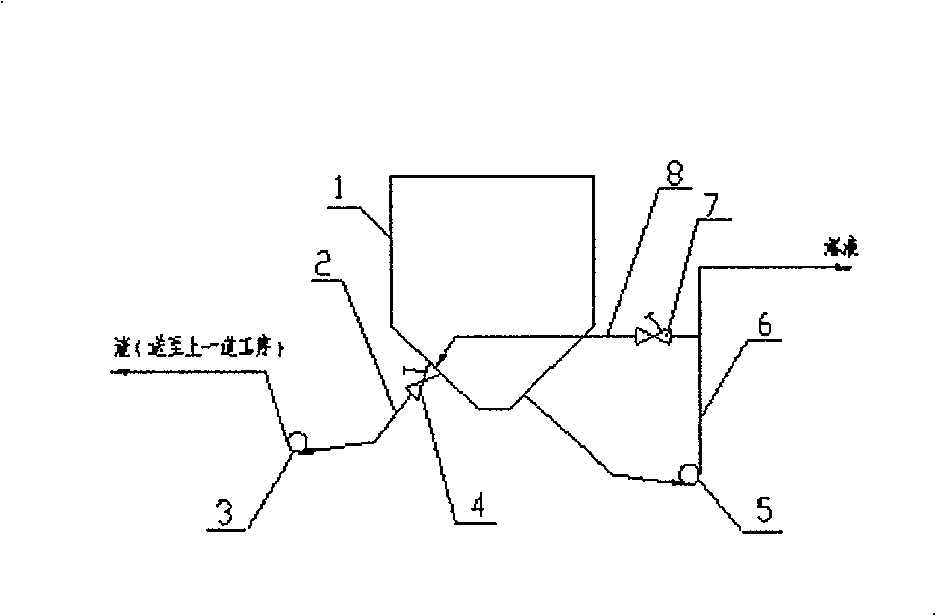

[0016] The embodiment of the present invention: a slag discharge port and a liquid discharge port are respectively opened on the bottom side of the storage tank 1, and the slag discharge port is connected with the slag discharge pipe 2. The slag discharge pipe 2 is equipped with a slag discharge pump 3, and the discharge port is connected with The drain pipe 6 is connected, and the drain pump 5 is installed in the drain pipe 6. One end of the branch pipe 8 is connected with the liquid discharge pipe 2, and the nozzle of the branch pipe 8 points to the slag discharge port. The bottom of the storage tank 1 has a tapered structure. A groove wall valve 4 is installed on the slag discharge port, and the groove wall valve 4 is connected with the slag discharge pipe 2. A valve 7 is installed in the branch pipe 8.

[0017] After the liquid-solid separated aqueous solution enters the storage tank 1, the suspended solids in the solution are continuously deposited to the conical bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com