Method for manufacturing circuit device

A manufacturing method and circuit device technology, which can be applied in the direction of multilayer circuit manufacturing, circuit, semiconductor/solid-state device manufacturing, etc., can solve the problem of the overall size of the semiconductor device becoming larger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

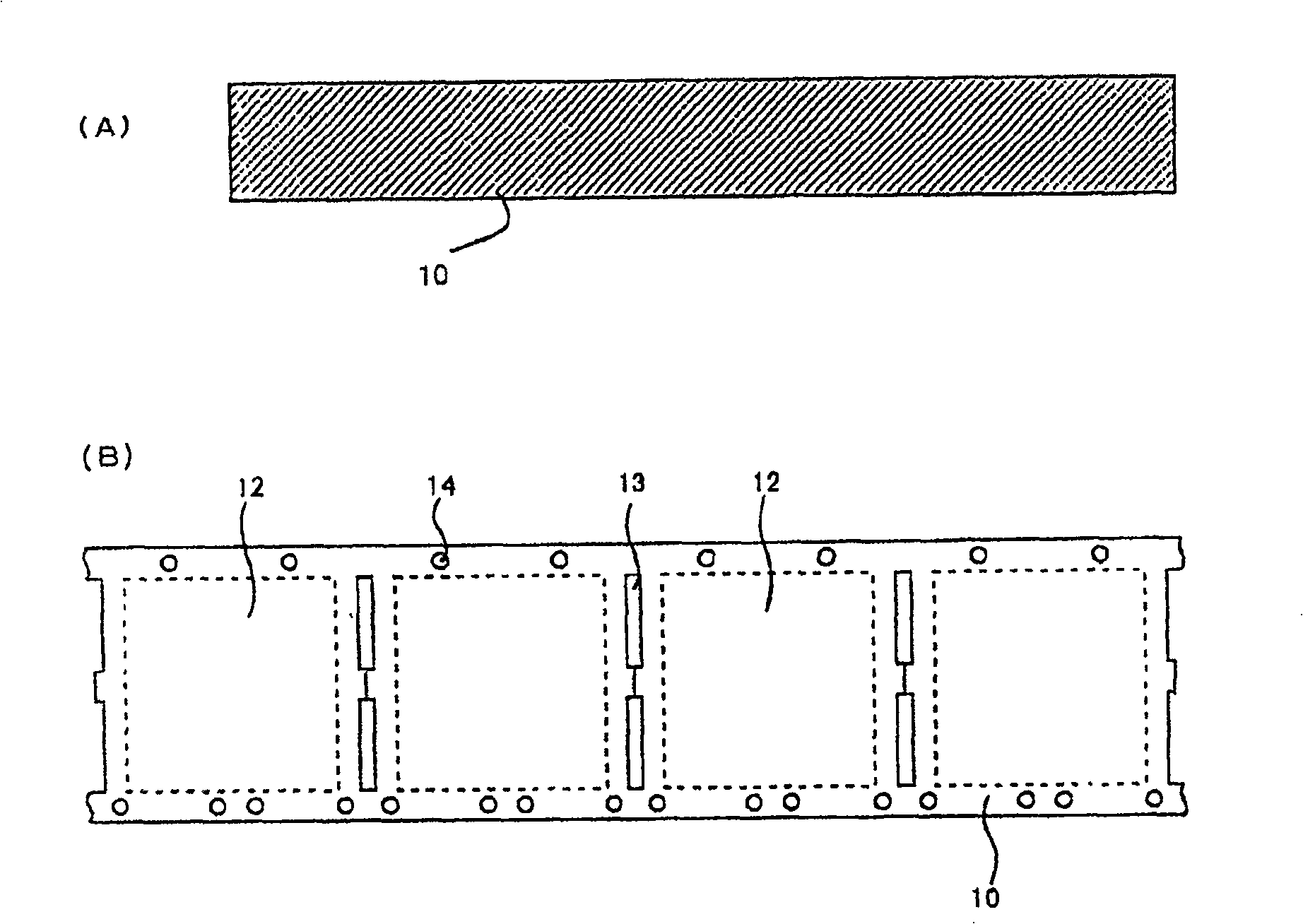

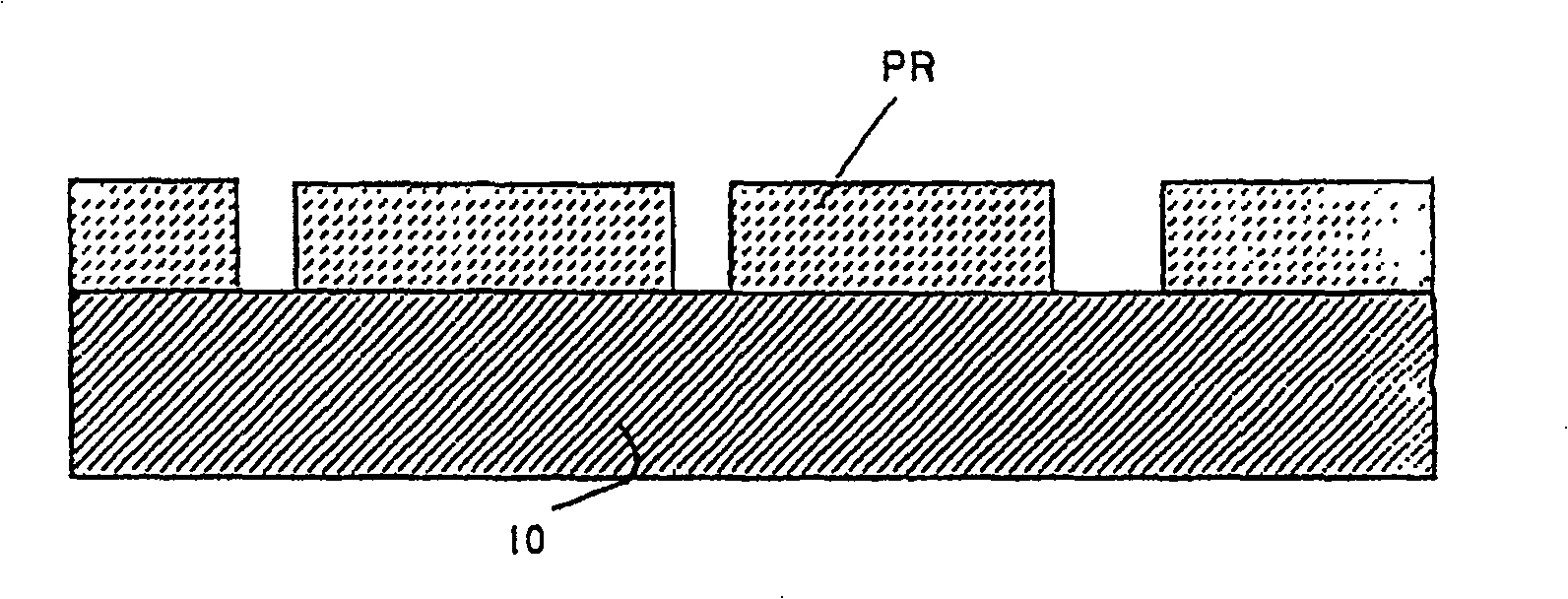

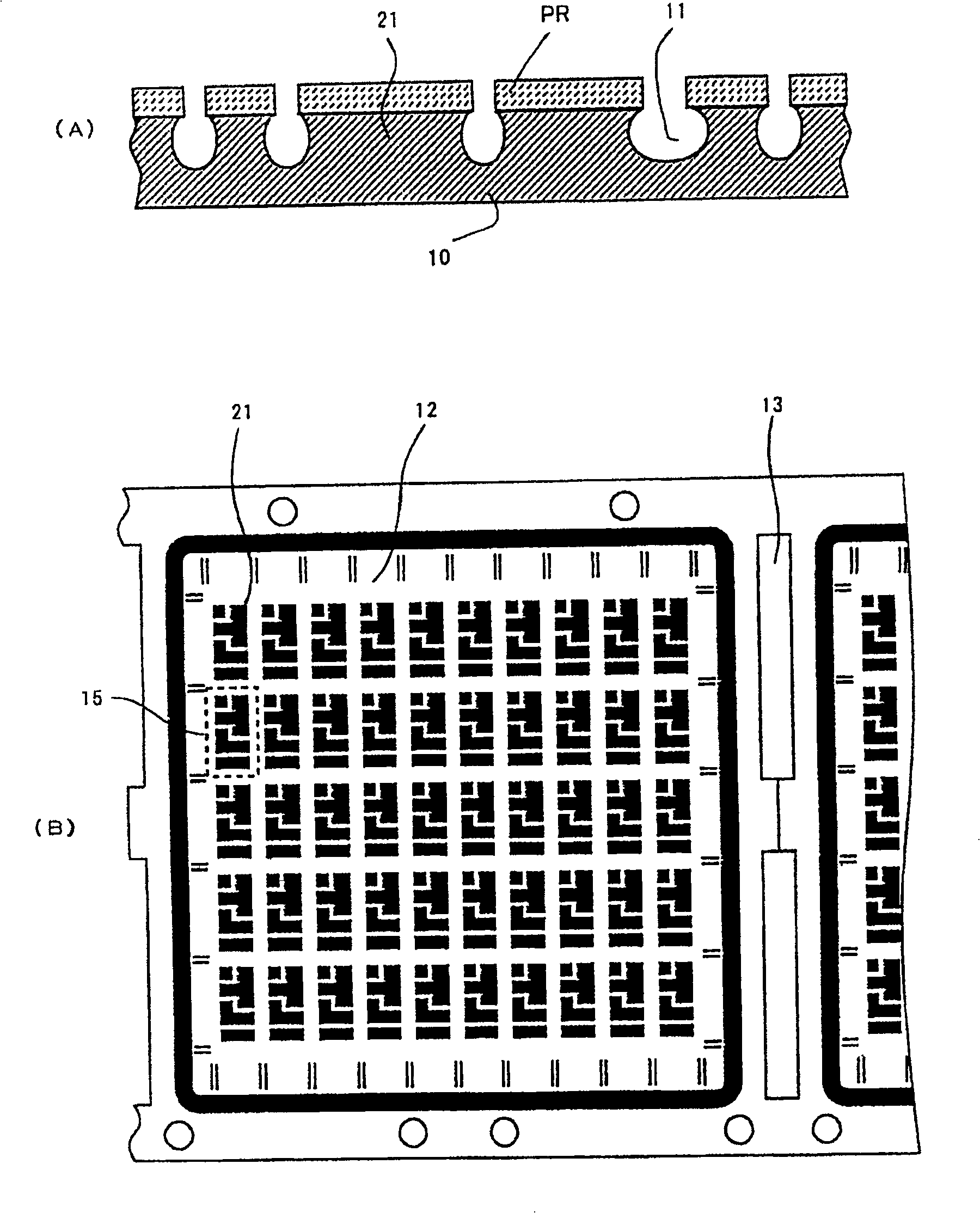

[0031] The manufacturing method of the circuit device of the present invention includes the following steps: a step of forming a conductive pattern 21 formed on the conductive foil 10 with a separation groove 11 formed on the surface and connected as a whole by the bottom; a step of installing a circuit element 22 at a predetermined position of the conductive pattern 21; In the step of sealing with the sealing resin 28 to cover the circuit element 22 and filling the separation groove 11 , the surface of the conductive foil 10 is irradiated with plasma to manufacture a circuit device. There are two methods of irradiating plasma. The first method is to irradiate plasma before mounting circuit element 22 , and the second method is to irradiate plasma after mounting circuit element 22 . Each of these steps will be described in detail below.

[0032] The first process of the present invention is, as Figure 1 ~ Figure 3 As shown, the process of forming the conductive pattern 21 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com