Bilateral dielectric rod clamping dual-electron-beam periodic zigzag metal wire slow-wave structure

A technology of slow wave structure and double electron injection, which is applied to the circuit components of transit-time electron tubes, can solve the problems of low output power, weak electric field, low coupling impedance, etc., achieve high output power and enhance interaction strength and the effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

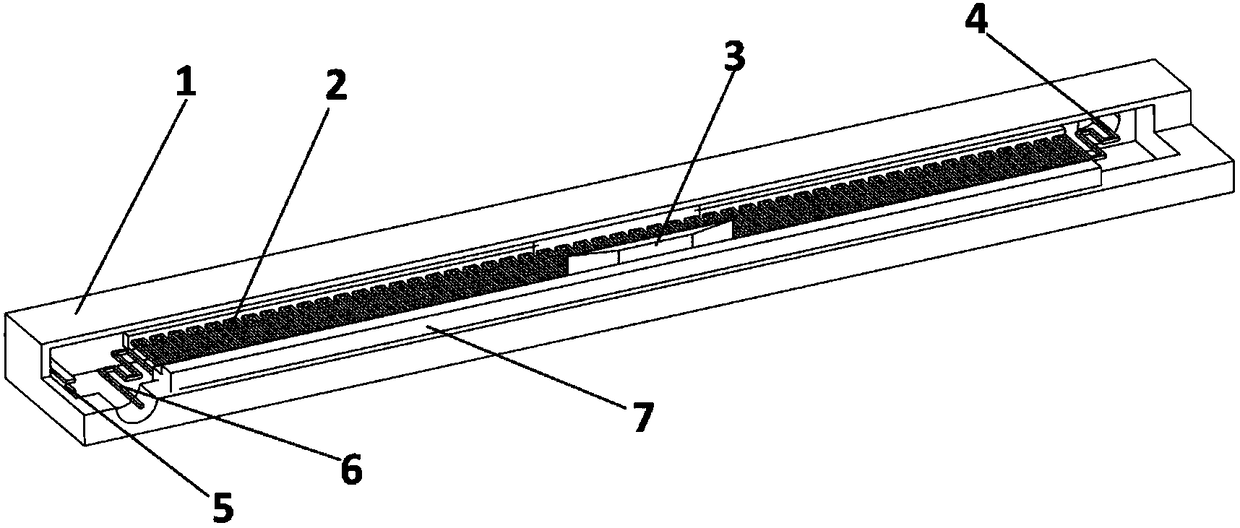

[0029] A slow-wave structure of double-electron injection periodic meandering metal wires clamped by dielectric rods on both sides, including a metal cavity 1, a cathode electron emitter 5 welded at one end of the metal cavity 1, and a slow-wave structure arranged on the metal cavity 1 The main body, the slow wave structure The main body includes a metal wire 2, a dielectric rod 7 arranged on both sides of the metal wire 2 for fixing, and an attenuator 3 arranged in the middle of the dielectric rod 7. A transition section is provided at both ends of the metal wire 2, and the transition section and the The metal cavity 2 is internally connected and forms a coaxial interface to the outside. The metal wire 2 adopts a uniform periodic meandering metal wire, and the metal wire 2 is connected end to end in a "several" shape.

[0030] Working principle: Dielectric rods 7 are used on both sides to support the slow-wave structure body, and a cathode electron emitter 5 is provided at one...

Embodiment 2

[0032] The cross section of the metal wire 2 is square, the side length w of the cross section is 0.07 mm, the lateral width h of a single period is 1.3 mm, and the distance wt between parallel segments of the metal wire 2 is 0.13 mm. The cross section of the dielectric rod 7 is "convex" shape, the total length d of the dielectric rod 7 is 20mm, and the lengths of each side are d1=0.3mm, d2=0.4mm, d3=0.38mm, d4=0.7mm. The cathode electron emitter 5 has a lateral dimension of 1.3 mm and a thickness of 0.07 mm. The transition section includes an input transition section 6 and an output transition section 4 that are reversely symmetrical, and its transverse heights are successively h=1.3mm, h1=1mm and h2=0.65mm, and its width is successively w4=0.145, w3= 0.152, w2=0.16 and w1=0.162. The cross section of the attenuator 3 is a standard trapezoid, the length of the upper side and the lower side are respectively S1=2mm and S2=3.6mm, and the height is S3=3.1mm.

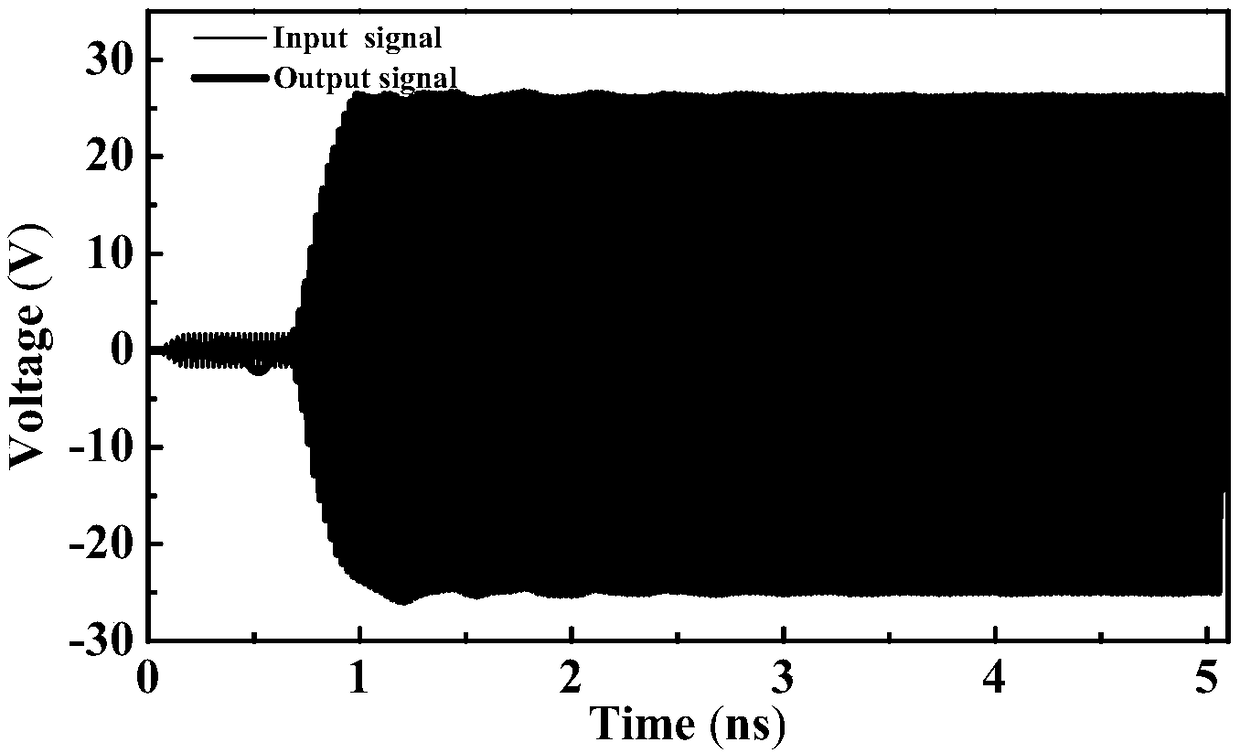

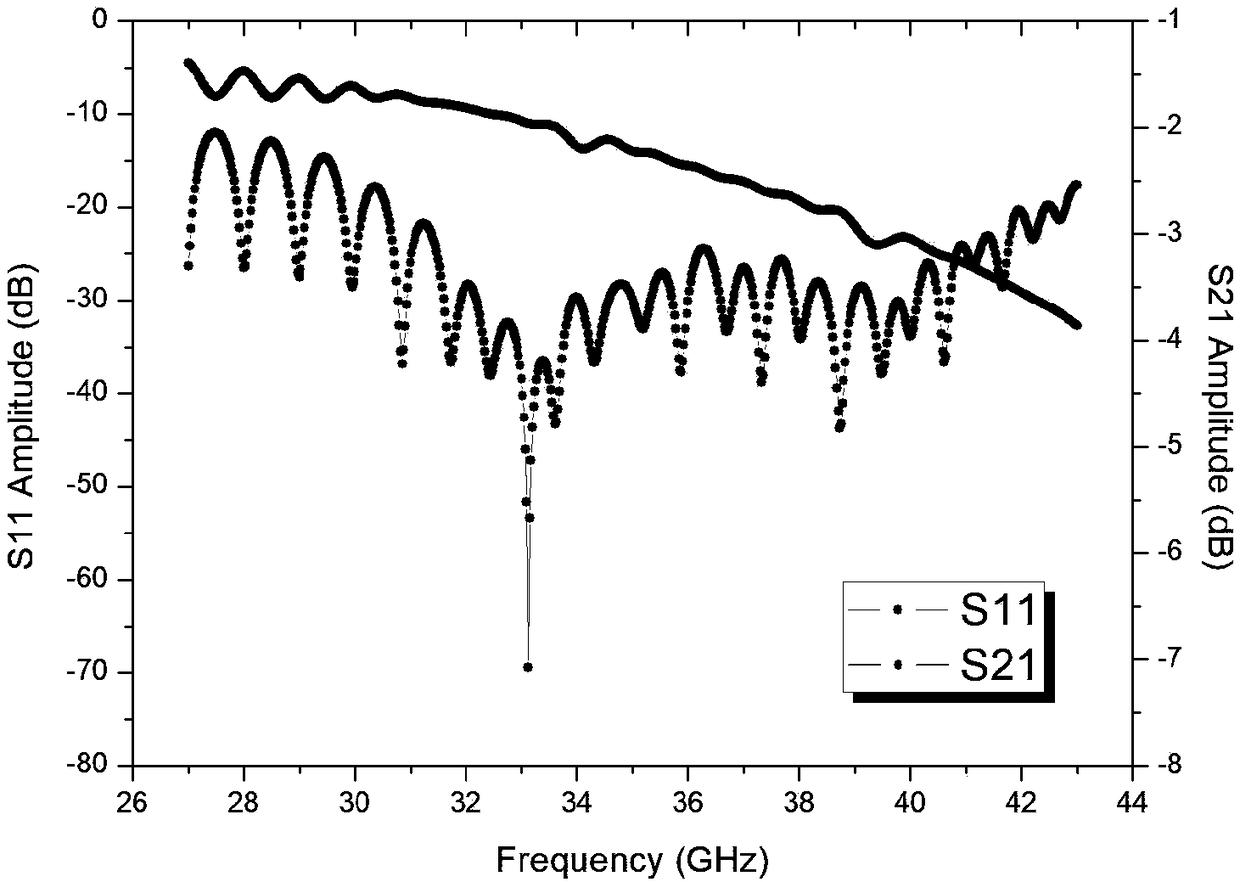

[0033] Effect anal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com