High magentic induction oriented electrical steel sheet and its manufacturing method

A technology of high magnetic induction orientation and electrical steel plate, applied in other manufacturing equipment/tools, manufacturing tools, metal rolling, etc., can solve the problems of many surface defects, reduced output, high manufacturing cost, etc., and achieve the purpose of suppressing the primary grain length Large, high-temperature annealing temperature reduction, the effect of ensuring the strength of the inhibitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A kind of manufacturing method of high magnetic induction oriented electrical steel sheet

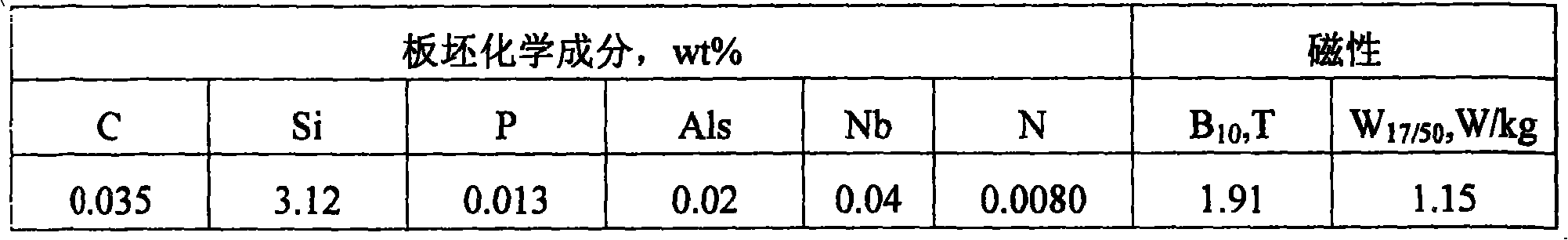

[0022] A new steel slab with a thickness of 210mm, its chemical composition is: C is 0.035wt%, Si is 3.12wt%, Als is 0.02wt%, Nb is 0.04wt%, N is 0.008wt%, P is 0.013wt%, the rest is Fe and unavoidable impurities, and the inhibitors are AlN and NbC.

[0023] Such as heating the slab to 1280°C and keeping it warm for 2 hours; then hot rolling, the reduction ratio of the last 3 passes of the hot rolling process is 10%, and the final rolling temperature is 850°C; after rolling, relax for 60 seconds, The hot-rolled coils with fine and uniform precipitates and structures are obtained, and the normalizing annealing of the hot-rolled coils is cancelled. Then perform rapid cooling and coiling, and the cooling rate of rapid cooling is 30° C. / second. Relaxation refers to maintaining a certain period of time under the condition that the temperature is basically constant.

[00...

Embodiment 2

[0029] Example 2 A high magnetic induction oriented electrical steel sheet and its manufacturing method

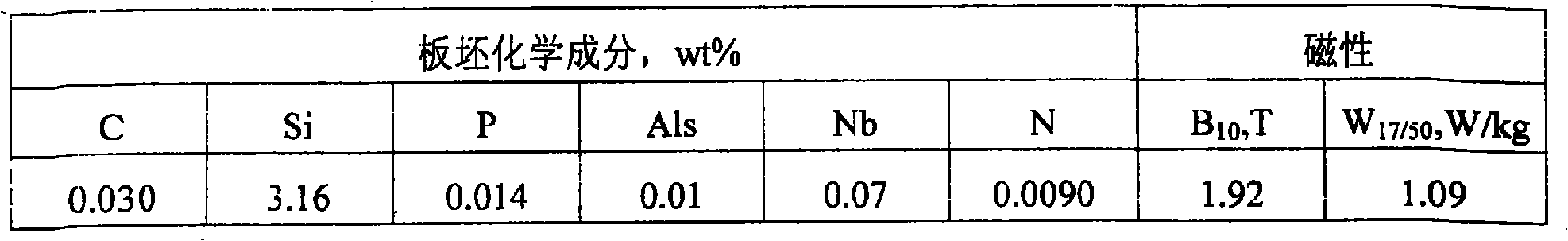

[0030] A new steel slab with a thickness of 210mm and its chemical composition is: C is 0.030wt%, Si is 3.16wt%, Als is 0.01wt%, Nb is 0.07wt%, N is 0.010wt%, P is 0.014wt%, the rest is Fe and unavoidable impurities; the inhibitors are AlN and NbN.

[0031] Heat the slab to 1250°C and keep it warm for 2 hours; then carry out hot rolling, the reduction rate of the last two passes of the hot rolling process is 25%, the final rolling temperature is 1050°C, and relax for 30 seconds after rolling to obtain For hot-rolled strips with fine and uniform precipitates and structures, the normalizing annealing of hot-rolled strips is cancelled. Then, rapid cooling is performed, and the cooling rate of the rapid cooling is 50° C. / second.

[0032] The first cold rolling to 0.75mm, followed by intermediate annealing, the intermediate annealing temperature is 1000°C, carried out in a ni...

example 3

[0037] Example 3 A high magnetic induction oriented electrical steel sheet and its manufacturing method

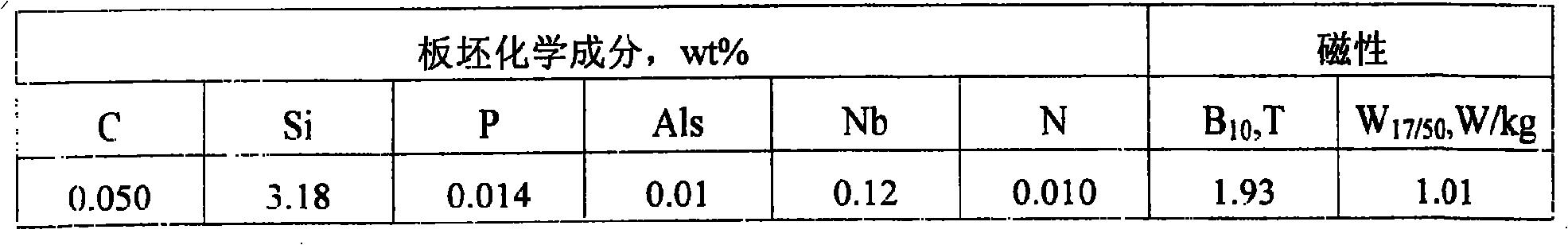

[0038] A new steel slab with a thickness of 210mm, its chemical composition is: C is 0.050wt%, Si is 3.18wt%, Als is 0.01wt%, Nb is 0.12wt%, N is 0.010wt%, P is 0.014wt%, the rest is Fe and unavoidable impurities, and the inhibitors are AlN, NbC and NbN.

[0039] The slab was heated to 1300° C. and kept for 2 hours; hot rolling was carried out again. The reduction ratio of the last pass of the hot rolling process was 28%, the final rolling temperature was 1000° C., and the rolling was relaxed for 40 seconds. Carry out rapid cooling again, the cooling rate of rapid cooling is 40 DEG C / second, obtains precipitate and structure all fine and uniform appropriate hot-rolled coil, cancels the normalization annealing of hot-rolled coil.

[0040] Carry out the first cold rolling to 0.83mm, and then carry out intermediate annealing. The intermediate annealing temperature is 1050°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com