Aircraft fuselage

A fuselage, aircraft fuselage technology, applied in the direction of fuselage, fuselage bulkhead, fuselage insulation, etc., can solve the problems of insufficient fire protection, unable to ensure the fire protection level of the internal area of the fuselage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

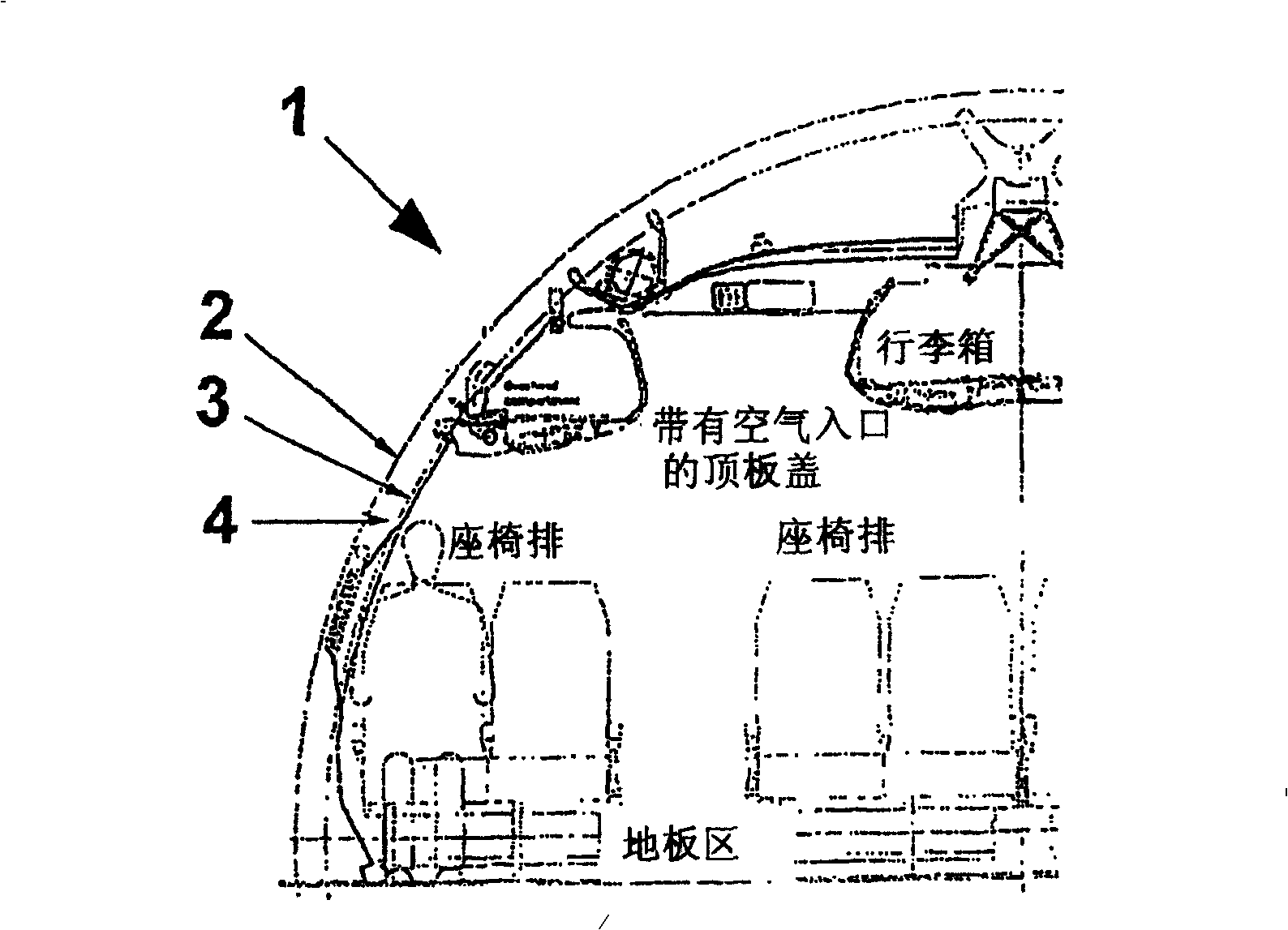

[0016] figure 1 The cross-section of the fuselage of the passenger aircraft is schematically shown, limited to the cross-sectional area of the aircraft cabin 1 . This structure will likely be familiar to experts in aircraft construction, and shows the relationship that the observer would know from this figure: the flammable inner cladding 3 is placed very close to the outer skin 2 (of the fuselage) when compared to When the outer skins are fitted together, they enclose a space in which the fuselage spacers ( figure 1 not shown). If the outer skin 2 , conventionally realized in aluminum material or aluminum alloy, is installed in this configuration, the observer will be aware of the extent of the type of fire described at the outset. figure 1 The additional parts and elements shown in , and integrated into the interior equipment and fuselage structure of the aircraft cabin (based on the example here) will not be described, as they are considered irrelevant to the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com