Cotton grasp mechanism adapted for reciprocation bale plucker

A cotton catching machine and cotton catching device technology, which is applied in the direction of fiber opening and cleaning machines, can solve the problems affecting the working efficiency of the blowing and carding system, the difference in fiber opening and grasping amount, and the single component of the grasped fiber, so as to achieve the guarantee The effect of fine grasping, small difference in grasping fibers, and reducing fiber depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

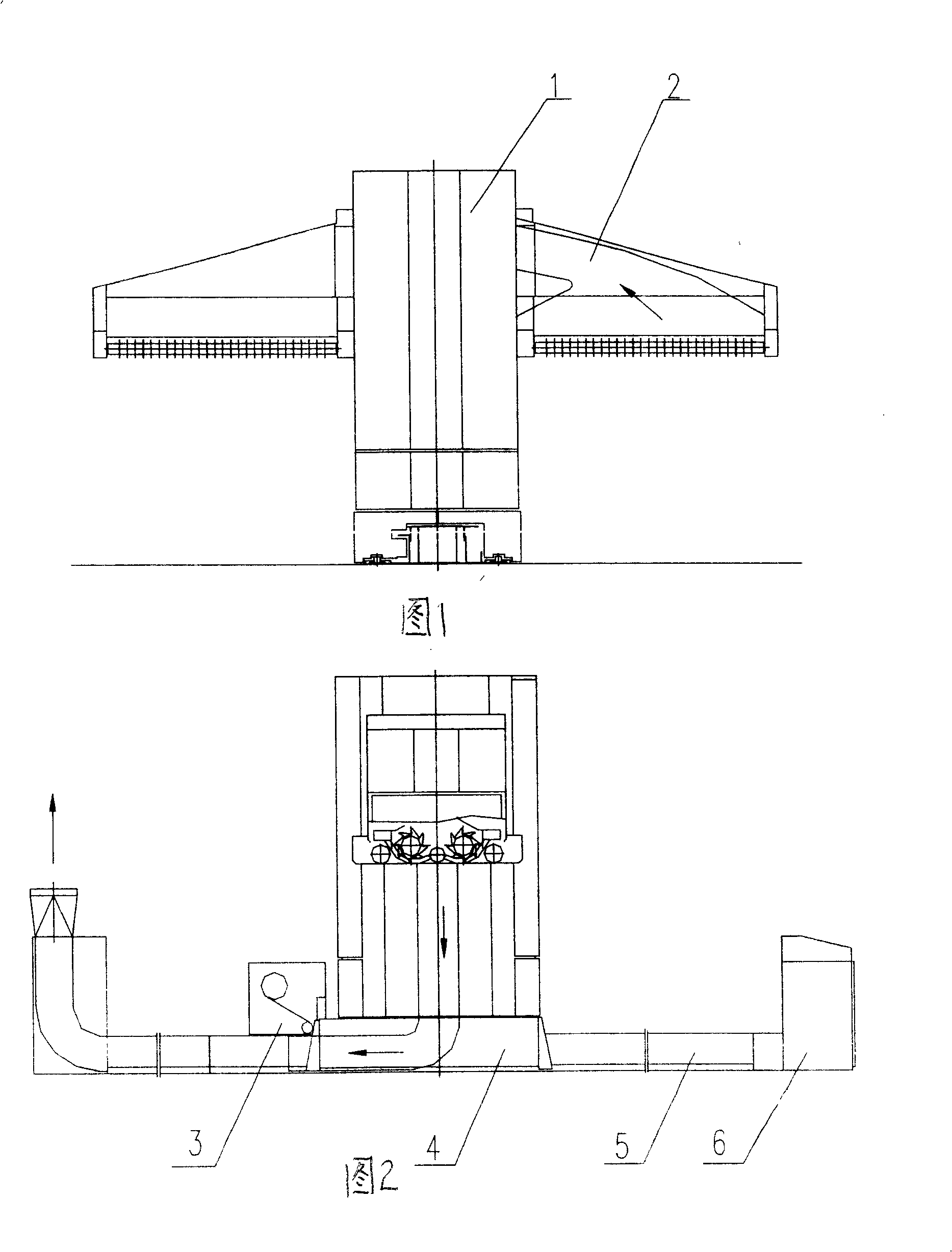

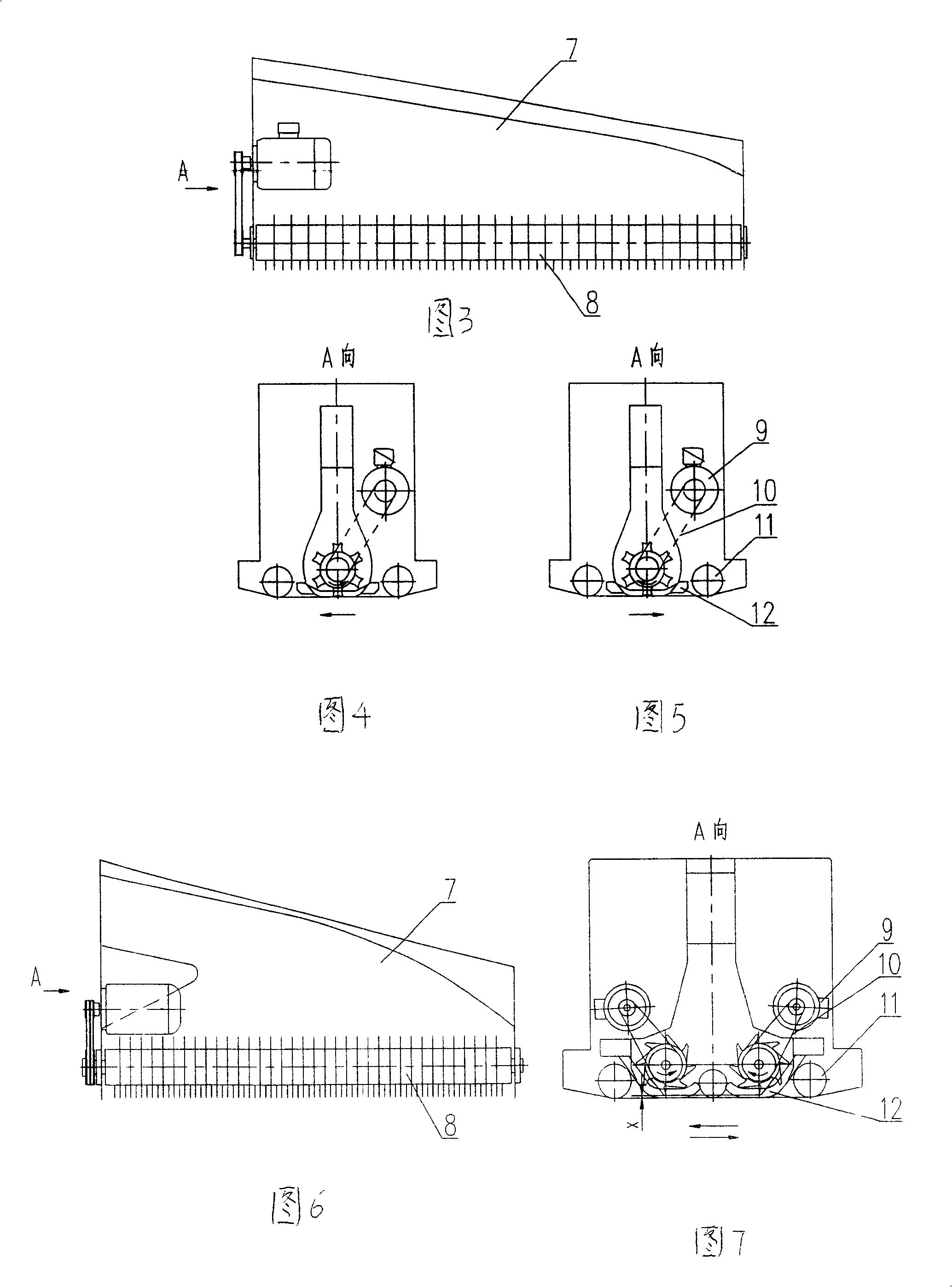

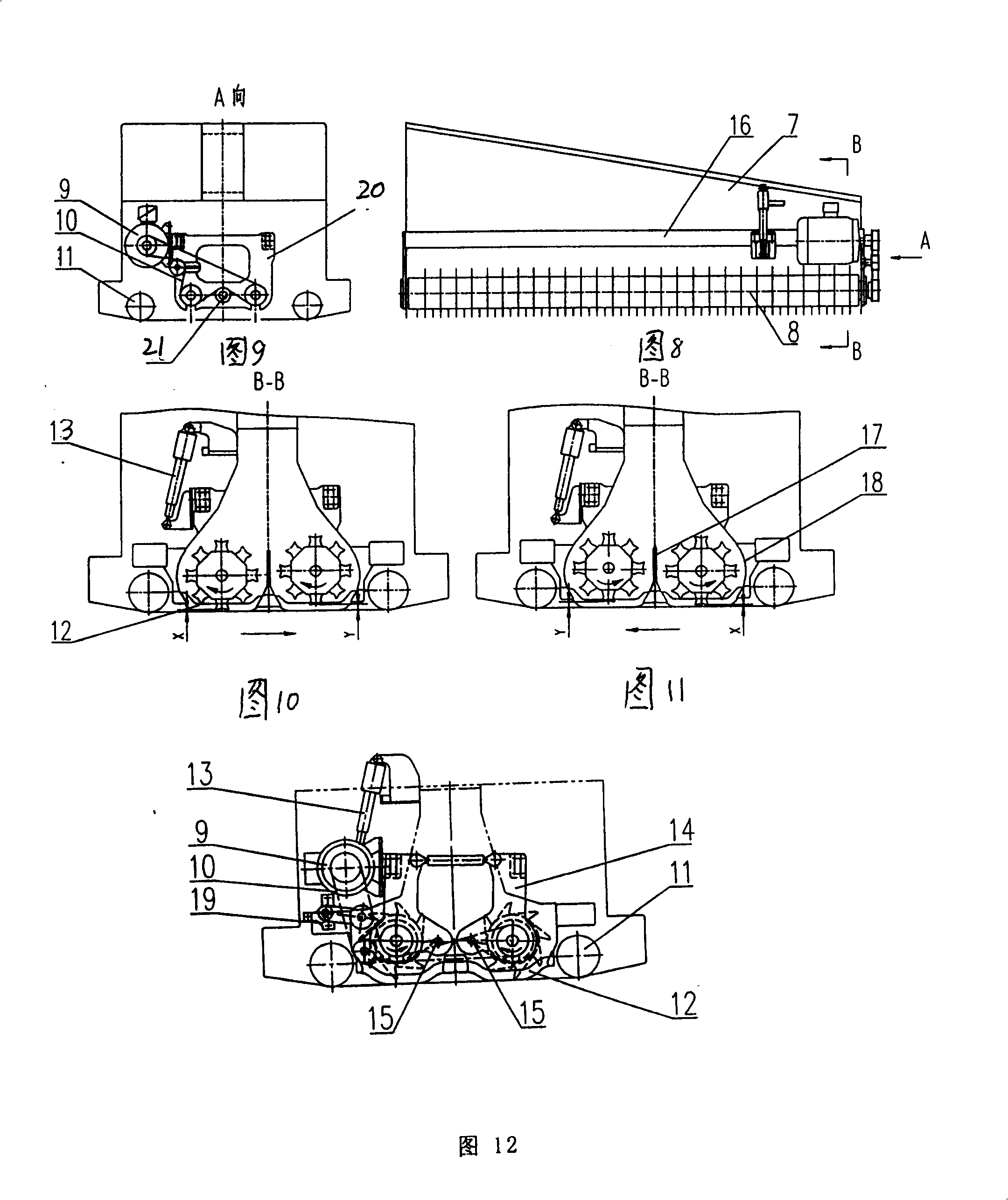

[0033] The present invention is further described below in conjunction with accompanying drawing:

[0034] As shown in Figures 8, 9, 10, 11, and 12, the present invention is applicable to the cotton catcher mechanism of the reciprocating cotton grabbing machine including the cotton grabbing arm frame 7 combined with the cotton grabbing machine turret 1, and the cotton grabbing arm The bottom of the frame 7 is hung with two swing rods 16 side by side by the vertical swing mechanism 13 along the length direction, and a support 14 for installing the beater 8 is fixedly connected to each two ends of each swing rod 16, and is positioned at the two swing rods 16. The left and right brackets 14 at the same end form a four-bar linkage mechanism through connecting pieces hinged to their upper and lower ends respectively. The two ends of the connecting rod are combined, and the lower ends of the corresponding sides are respectively combined with the wallboard 20 arranged at the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com