Aseismic damper for wooden house formed of superplastic alloy

A technology of superplasticity and shock absorber, which is applied in the direction of elastic shock absorber, shock absorber, shock absorber, etc., and can solve the problems that the intersection of columns and beams cannot be tightly accommodated, costs are required, and it is not easy to reduce costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

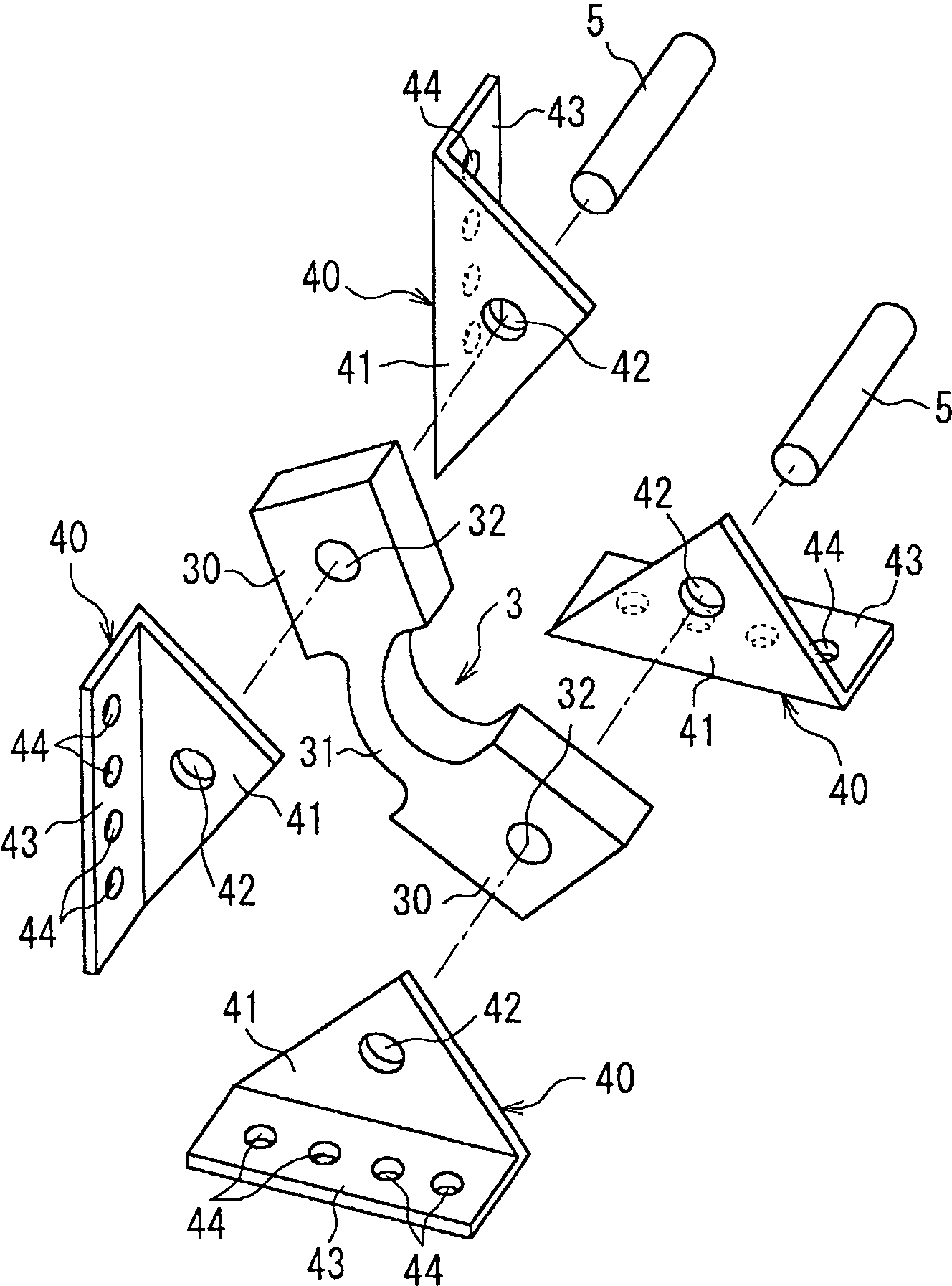

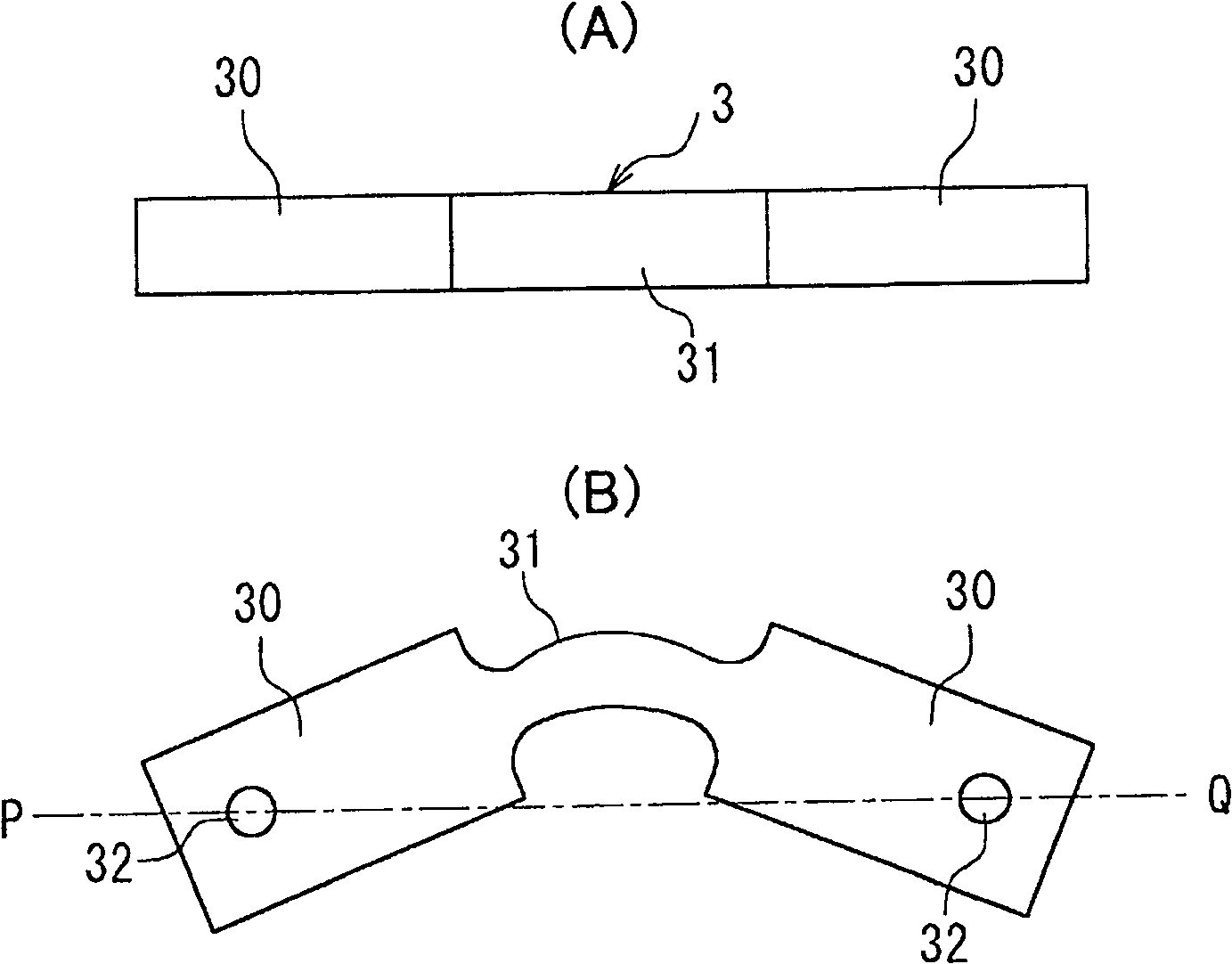

[0045] A preferred embodiment of the present invention includes a thin deformed part bent in an arc shape with a substantially parallel width in the inner direction of the column-beam frame, and a deformed part sufficiently expanded to a large size so that both ends thereof are not deformed. The supporting part is configured to at least combine the above-mentioned anti-seismic shock absorber made of superplastic alloy with the above-mentioned deformation part, and the installation accessories for fixing the above-mentioned supporting parts at both ends of the above-mentioned anti-seismic shock absorber to the column-beam junction of the house.

[0046] In order to make the above-mentioned deformation part perform the same deformation from the end to the center, the cross-sectional area and section coefficient gradually increase from the end to the center.

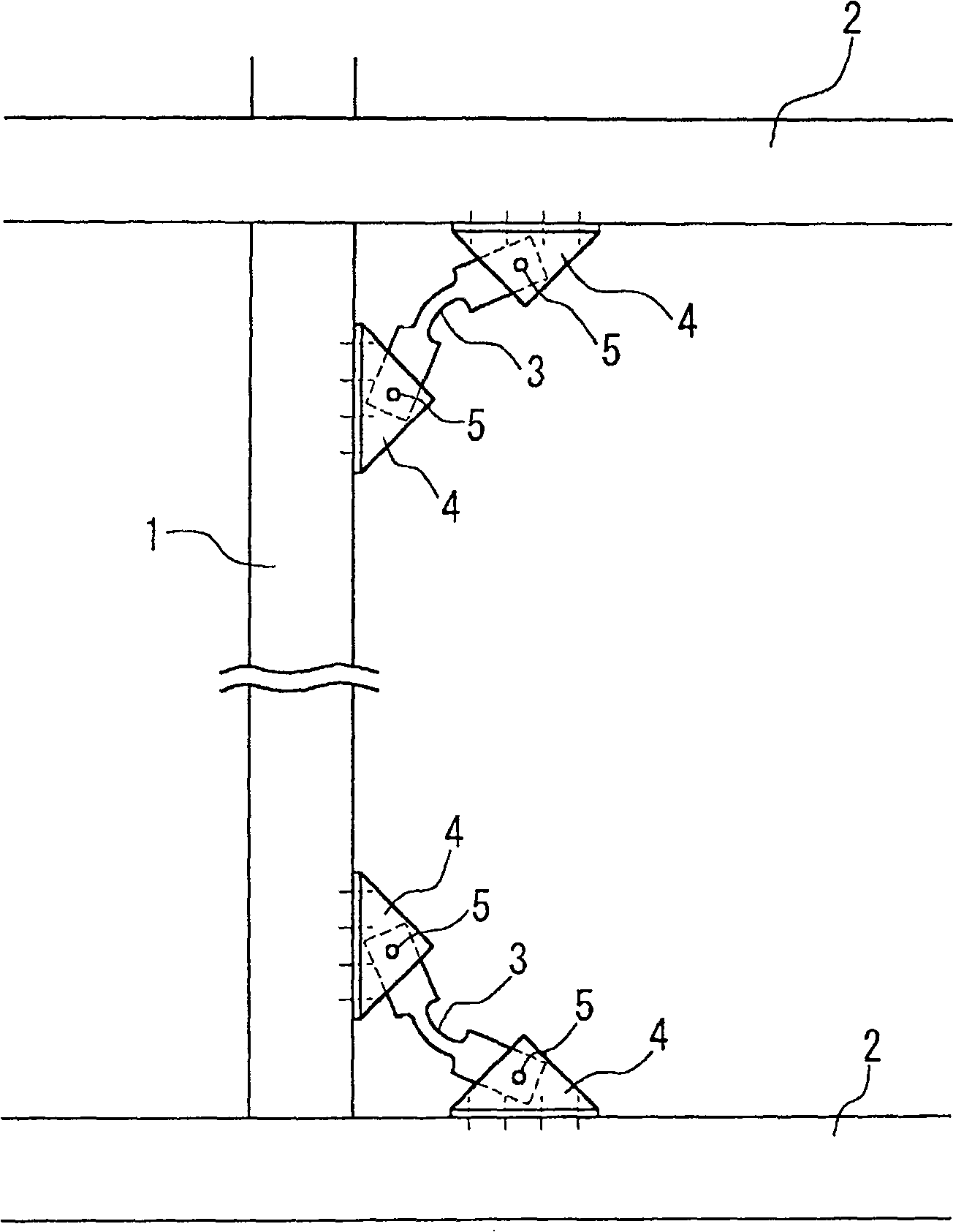

[0047] The first figure shows that on the junction of the column 1 and the beam 2 of the wooden structure house, the shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com