Method for preparing soil for analogue test

A technology of simulation test and sample soil, which is applied in the field of preparation of soil for indoor bucket foundation small model test and centrifuge test, to shorten the research work process and save research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preparation steps:

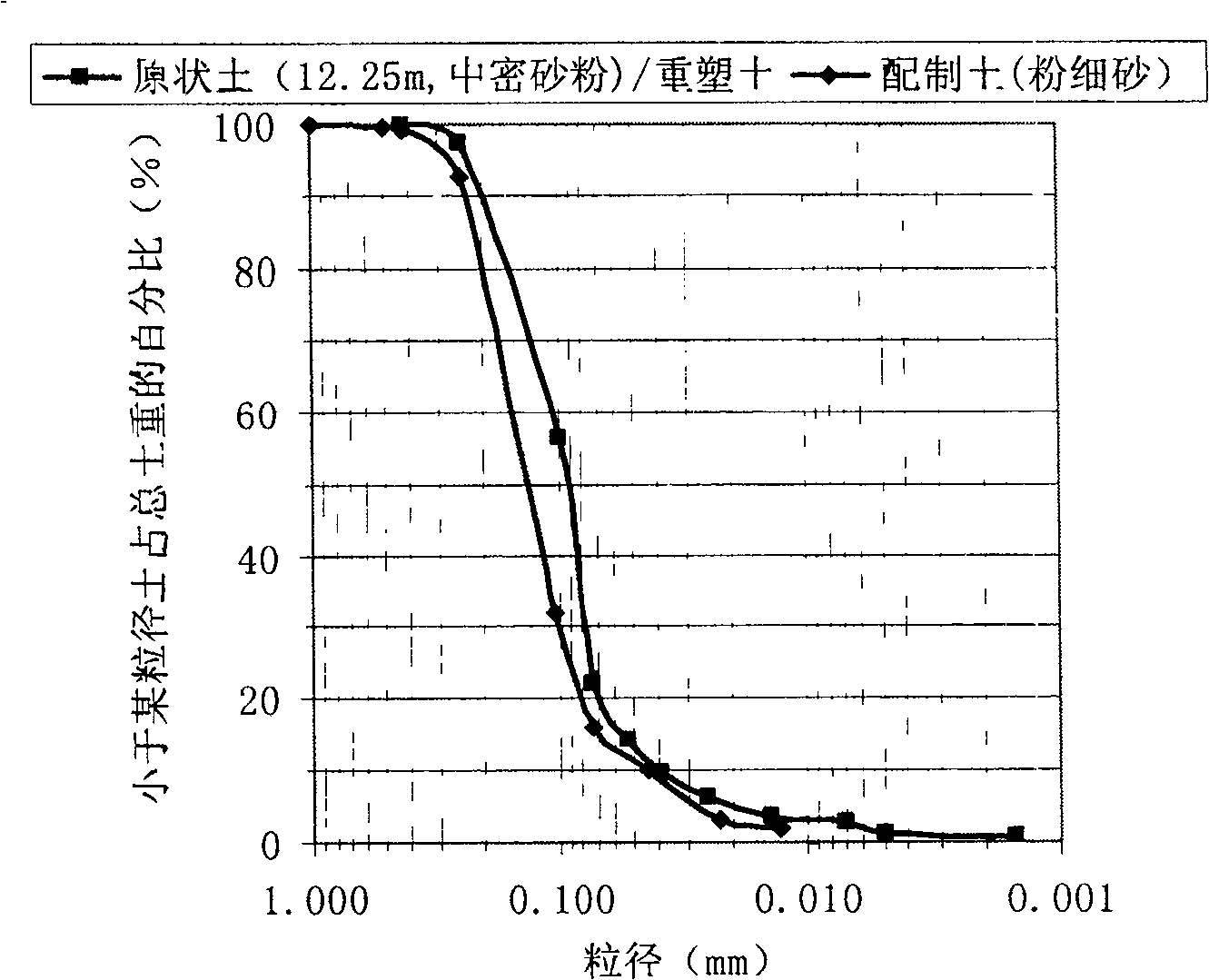

[0014] 1) Take an appropriate amount of undisturbed soil for physical property experiments and analysis to obtain particle gradation, density, and permeability coefficient.

[0015] 2) Obtain the particle gradation curve of undisturbed soil by above-mentioned;

[0016] 3) Prepare sampling soil (fine sand in Zhangzhou, silty clay at a construction site in Beijing, mixed fine sand) so that it is close to the particle gradation curve in step 2);

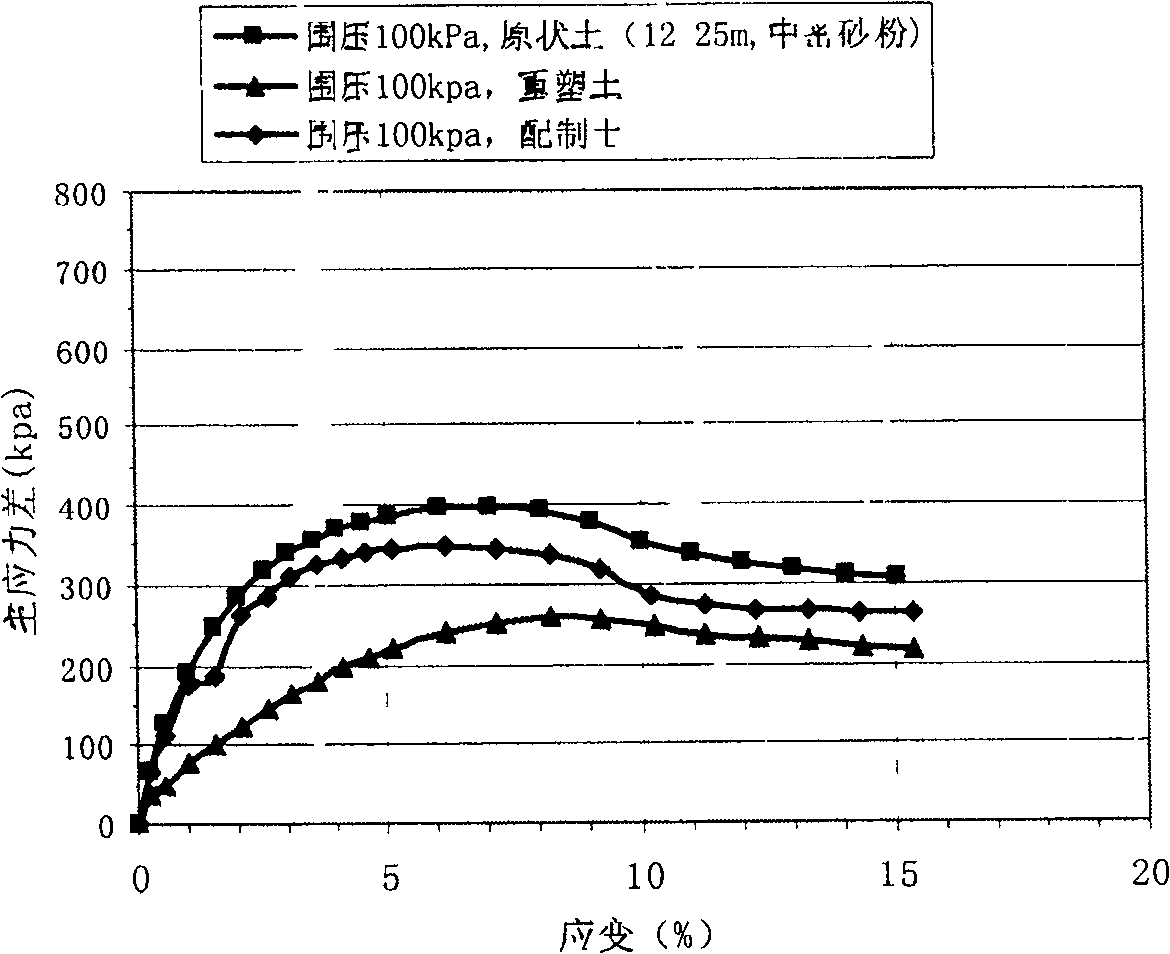

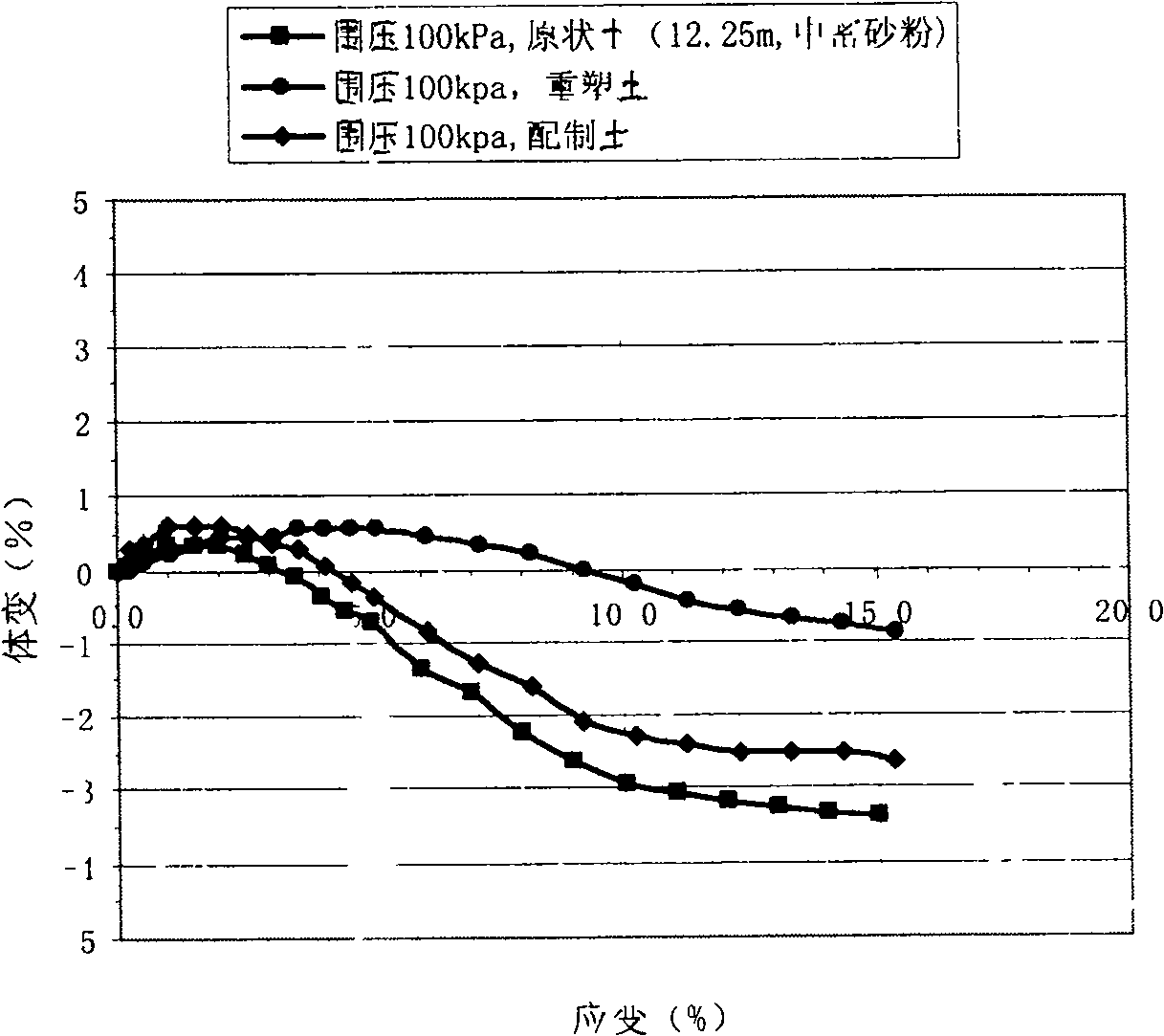

[0017] 4) For the sample soil in step 3, according to the density of the undisturbed soil, carry out the experiment and analysis of the mechanical properties of the triaxial compression shear. If the stress is large and the permeability coefficient is large, the sample soil is re-mixed, and the fine-grained soil is added in an appropriate amount. If the stress is small and the permeability coefficient is small, re-mix the sampled soil and increase the amount of coarse-grained soil;

[0018] 5) When the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com