High pressure nitrogen storage bottle made of PBO fiber and carbon fiber composite material and its preparation method

A composite material and carbon fiber technology, used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc. problems, to achieve the effects of high safety and reliability, structural optimization, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

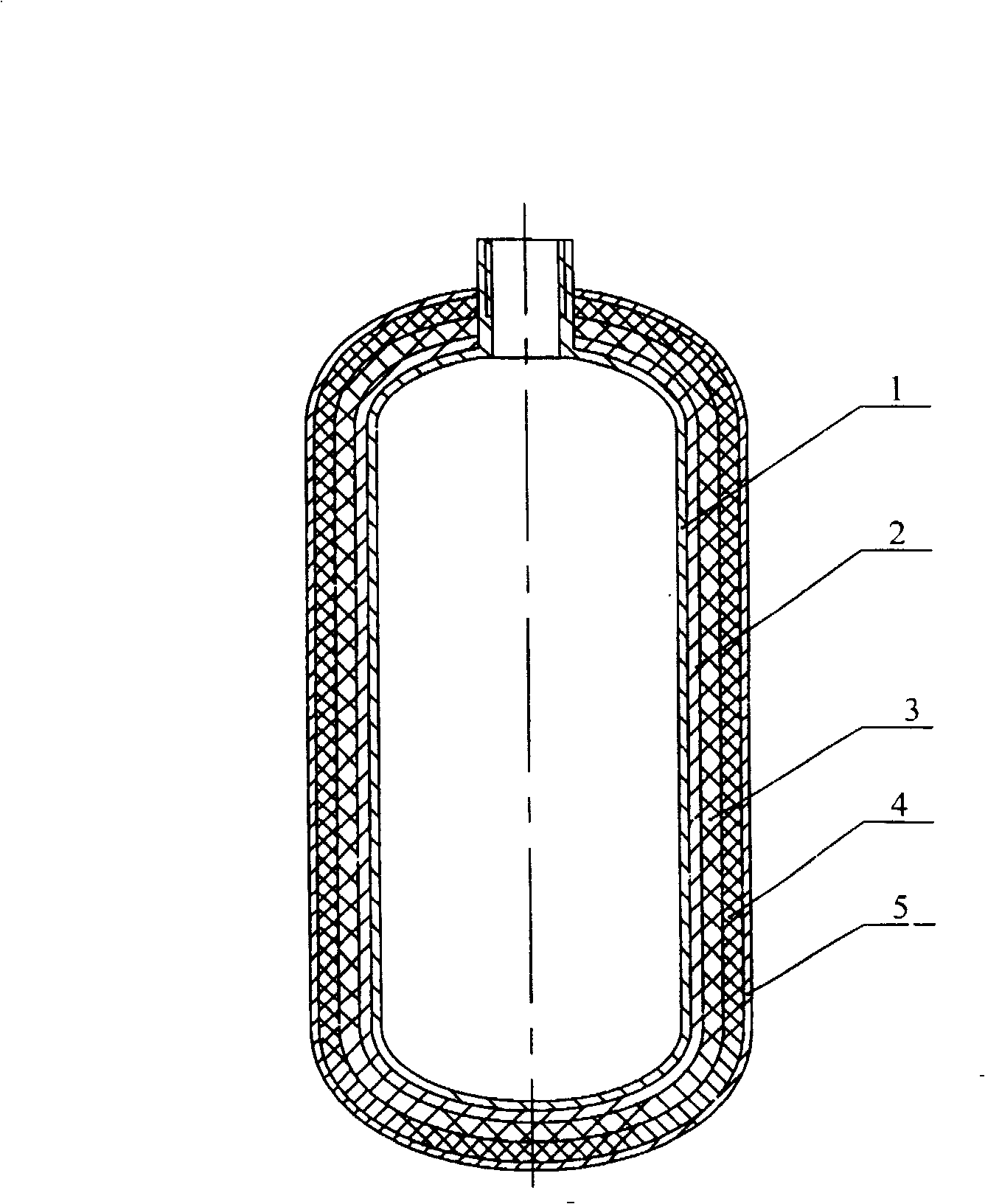

[0014] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment consists of an inner lining layer 1, an adhesive layer 2, a fiber composite material layer, and a glass fiber composite material outer protective layer 5. The fiber composite material layer is composed of a carbon fiber composite material inner structure layer 3 and a PBO fiber composite material outer structure layer. 4 components, the inner lining layer 1 adopts the neoprene inner lining layer 1, the outer surface of the neoprene inner lining layer 1 is bonded to the adhesive layer 2, and the outer surface of the adhesive layer 2 is bonded to the carbon fiber composite inner structure layer 3, the inner surface of the PBO fiber composite material outer structure layer 4 is wound on the outer surface of the carbon fiber composite material inner structure layer 3, and the outer surface of the PBO fiber composite material outer structure layer 4 is wrapped around ...

specific Embodiment approach 2

[0016] Specific embodiment two: the preparation method of this embodiment adopts the following steps:

[0017] Step 1. First, paint an interface adhesive layer 2 with a thickness of 0.5mm to 0.6mm on the neoprene inner lining layer 1. When painting the adhesive layer 2, ensure that the coating is uniform and free of bubbles; The inner lining layer 1 is formed by pasting two layers of raw rubber sheets with a thickness of 2mm to 3mm on the cylindrical bottle body mold. The raw rubber sheets are vulcanized by heating and curing with the fiber composite material of the bottle body to form an overall airtight function. Floor.

[0018] Step 2: On the outer surface of the adhesive layer 2, the carbon fiber composite material inner structure layer 3 is produced by using a fiber wet winding process, followed by one to two layers of spiral winding, two layers of hoop winding, one to two layers of spiral winding, and one to two layers of spiral winding. Two layers of hoop winding, one ...

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the coating thickness of the elastic adhesive layer 2 in step one is 0.5 mm; in step two, one layer of helical winding and two layers of hoop winding are performed in sequence , one layer of helical winding, one layer of hoop winding, one layer of helical winding and one layer of hoop winding, the winding angle of helical winding is 16°, the thickness of each winding layer is 0.6mm, and the inner structure layer of carbon fiber hybrid composite material 3 has a thickness of 4.2 mm; in step 3, one layer of helical winding, one layer of hoop winding, two layers of helical winding, and one layer of hoop winding are used in sequence, and the winding angle of helical winding is 16°. The thickness is 0.4mm, and the thickness of the outer structural layer 4 of the PBO fiber composite material is 2mm; in step 4, the second layer of helical winding and the second layer of glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com