Preparation method of sterilization type easy-to-tear sealing cover film

A sealing cap, sterilization type technology, applied in the field of preparation of sterilized easy-tear sealing cap film, can solve the problem of inconvenient use of sealing, achieve stable quality, clean sealing position without residue, good high temperature sterilization performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

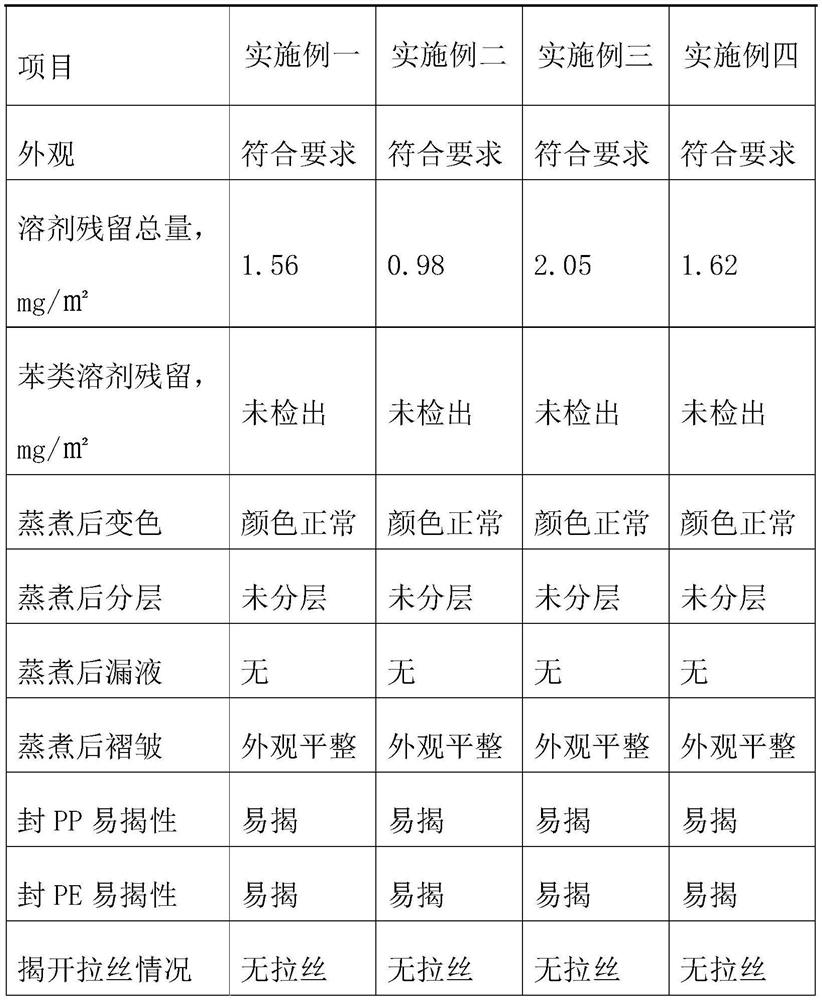

Examples

Embodiment 1

[0014] A method for preparing a sterilized easy-tear lid film, which is used to prepare a sterilized easy-tear lid film. The sterilized easy-tear lid film includes a body, and the body includes but is not limited to A printing base layer and a heat-sealing layer. There is a printing layer on the printing base layer. The printing layer is printed by cooking ink, and the printing base layer and the heat-sealing layer are bonded by a two-component polyurethane adhesive The printed base layer is aluminum foil, the heat-sealing layer is polyethylene, and the thickness of the aluminum foil is equal to 50um, and the thickness of the heat-sealing layer is equal to 70um. The preparation method comprises the following steps:

[0015] Step 1: Prepare the printing base layer: install the aluminum foil on the unwinding frame of the gravure printing machine, then apply the ink on the surface of the printing base layer through the gravure printing machine, and dry the aluminum foil. The print...

Embodiment 2

[0018] A method for preparing a sterilized easy-tear lid film, which is used to prepare a sterilized easy-tear lid film. The sterilized easy-tear lid film includes a body, and the body includes but is not limited to A printing base layer and a heat-sealing layer. There is a printing layer on the printing base layer. The printing layer is printed by cooking ink, and the printing base layer and the heat-sealing layer are bonded by a two-component polyurethane adhesive The printing base layer is aluminum foil, the heat-sealing layer is cast polypropylene, and the thickness of the aluminum foil is equal to 50um, and the thickness of the heat-sealing layer is equal to 70um. The preparation method comprises the following steps:

[0019] Step 1: Prepare the printing base layer: install the aluminum foil on the unwinding frame of the gravure printing machine, then apply the ink on the surface of the aluminum foil through the gravure printing machine, and dry the aluminum foil. The prin...

Embodiment 3

[0022] A method for preparing a sterilized easy-tear lid film, which is used to prepare a sterilized easy-tear lid film. The sterilized easy-tear lid film includes a body, and the body includes but is not limited to A printing base layer and a heat-sealing layer. There is a printing layer on the printing base layer. The printing layer is printed by cooking ink, and the printing base layer and the heat-sealing layer are bonded by a two-component polyurethane adhesive The printed base layer is a biaxially oriented polyester film, the heat-sealing layer is polyethylene, and the thickness of the printed base layer is equal to 7um, and the thickness of the heat-sealing layer is equal to 65um. An intermediate layer is also provided between the sealing layers, the intermediate layer is aluminum foil, the thickness of the intermediate layer is equal to 45um, and the preparation method comprises the following steps:

[0023] Step 1: Prepare the printing base layer: install the biaxiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com