Acid resistance and high temperature resistance antiseptic waterborne coating for inner wall of pop can

A technology of pop-top cans and high temperature resistance, applied in the direction of coating, etc., can solve the problems of large coating film thickness, food can storage, hidden dangers of hygiene and safety, low recycling rate of powder materials, etc., and achieve good acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

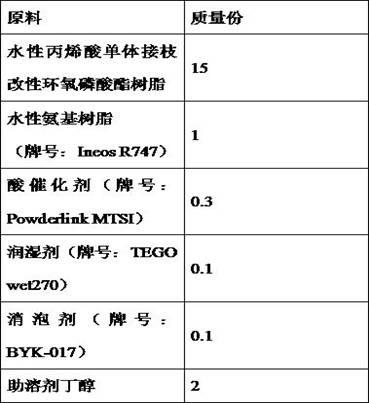

[0034] A kind of acid-resistant, high-temperature sterilization-resistant water-based paint for the inner wall of pop cans, the composition of its raw materials is as follows in Table 1:

[0035] Table 1: Raw material composition of an acid-resistant, high-temperature sterilization-resistant water-based coating for the inner wall of pop-top cans

[0036]

Embodiment 2

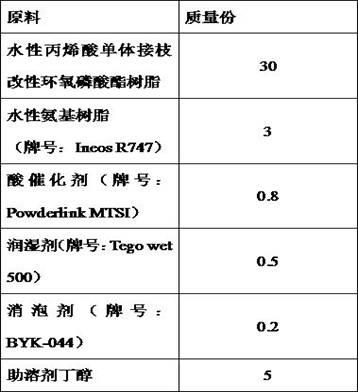

[0038] A kind of acid-resistant, high-temperature sterilization-resistant water-based paint for the inner wall of pop-top cans, the composition of its raw materials is as follows in Table 2:

[0039] Table 2: Raw material composition of an acid-resistant, high-temperature sterilization-resistant water-based coating for the inner wall of pop-top cans

[0040]

Embodiment 3

[0042] A water-based coating for the inner wall of pop cans with acid resistance and high temperature sterilization resistance, the composition of its raw materials is as follows in Table 3:

[0043] Table 3: Raw material composition of an acid-resistant, high-temperature sterilization-resistant water-based coating for the inner wall of pop-top cans

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com