Central spray multiolayer rotary liquid atomizing jet nozzle

A liquid atomization and rotary technology, which is applied to liquid spray devices, spray devices, spray devices, etc., can solve the problems of weakening heat and mass transfer effects, uneven spatial distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The central spray multi-layer rotary liquid atomizing nozzle of the present invention relies on pressure to accelerate the liquid to form a rotating liquid film or liquid column, and the liquid film or liquid column ruptures to form liquid droplets, thereby realizing the purpose of liquid atomization.

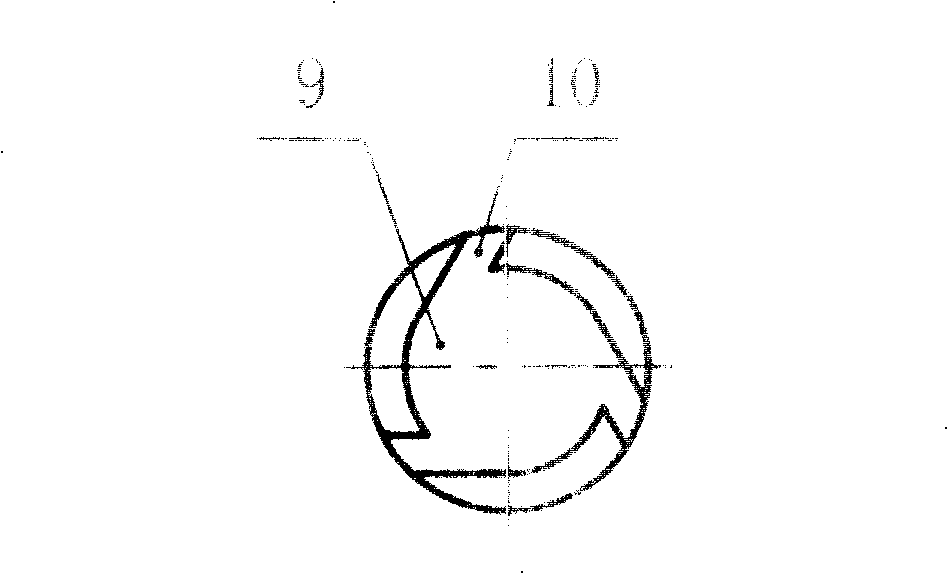

[0014] The central spray multi-layer rotary liquid atomizing nozzle of the present invention can accelerate the liquid into a rotating liquid film or liquid column in three ways: circle, cone and helix.

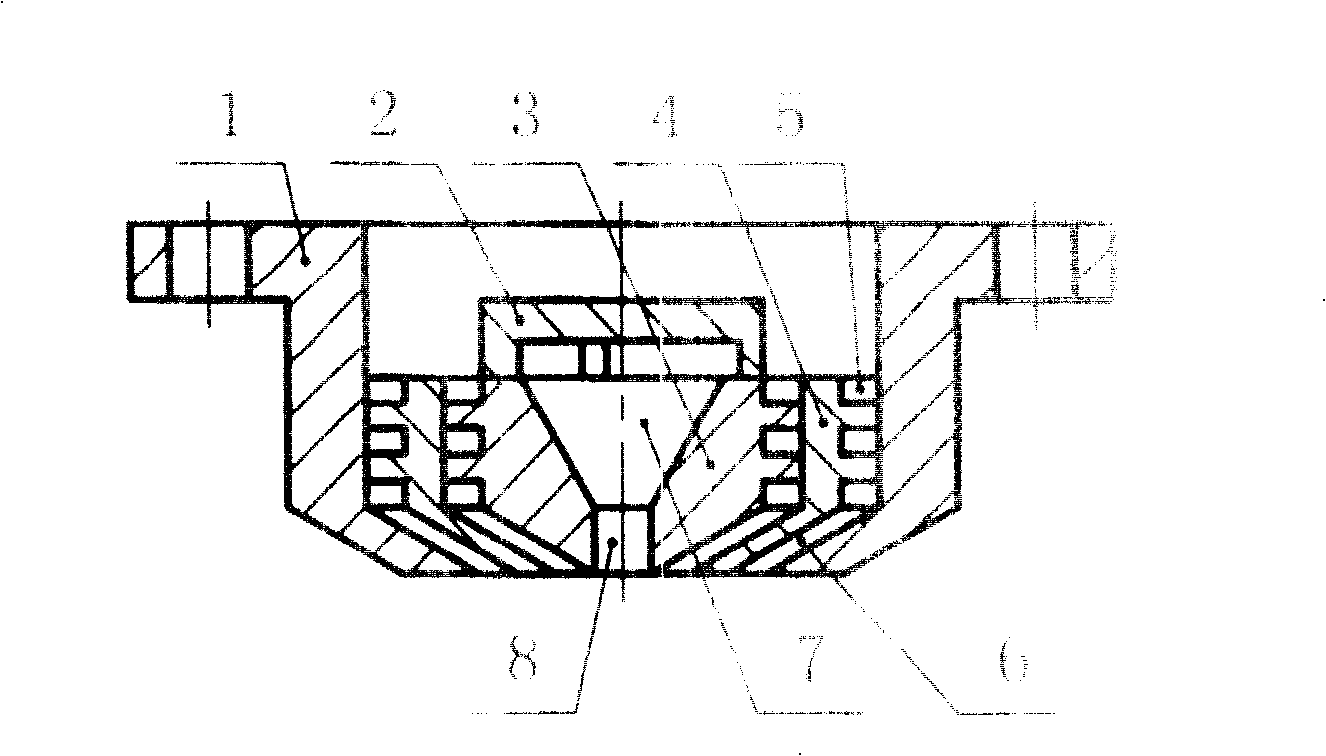

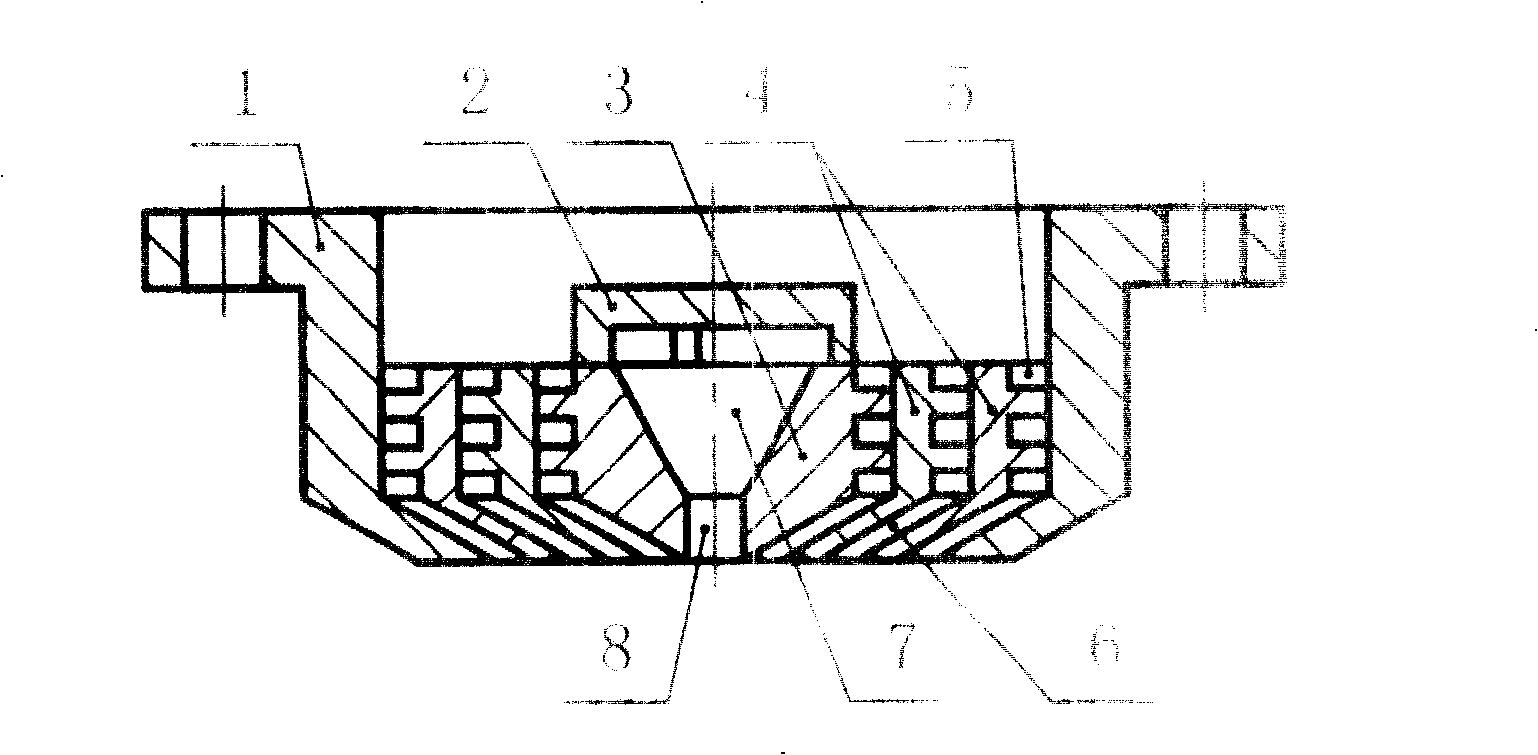

[0015] The structure of the central spray multilayer rotary liquid atomizing nozzle of the present invention is as follows: figure 1 As shown, it includes a shell 1, the shape of the inner cavity of the shell 1 is hollow, and the two ends of the shell 1 respectively form the liquid inlet and the liquid outlet. At the axial position of the inner cavity of the shell 1, there are conical rotators connected to each other 3 and a circular rotator 2, an axial end of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com