Superheat degree-based aluminum electrolysis energy balance adjusting method and system and aluminum electrolytic cell

A technology of energy balance and adjustment method, applied in heat storage equipment, energy storage, indirect heat exchangers, etc., can solve the problems of difficult to optimize the electrolysis process, difficult to achieve optimal aluminum electrolysis process, and less real-time data collection. , to achieve the effect of safety, stability and energy saving optimization, short cycle, safety, stability and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] Example of aluminum electrolytic cell:

[0041] Hardware parts:

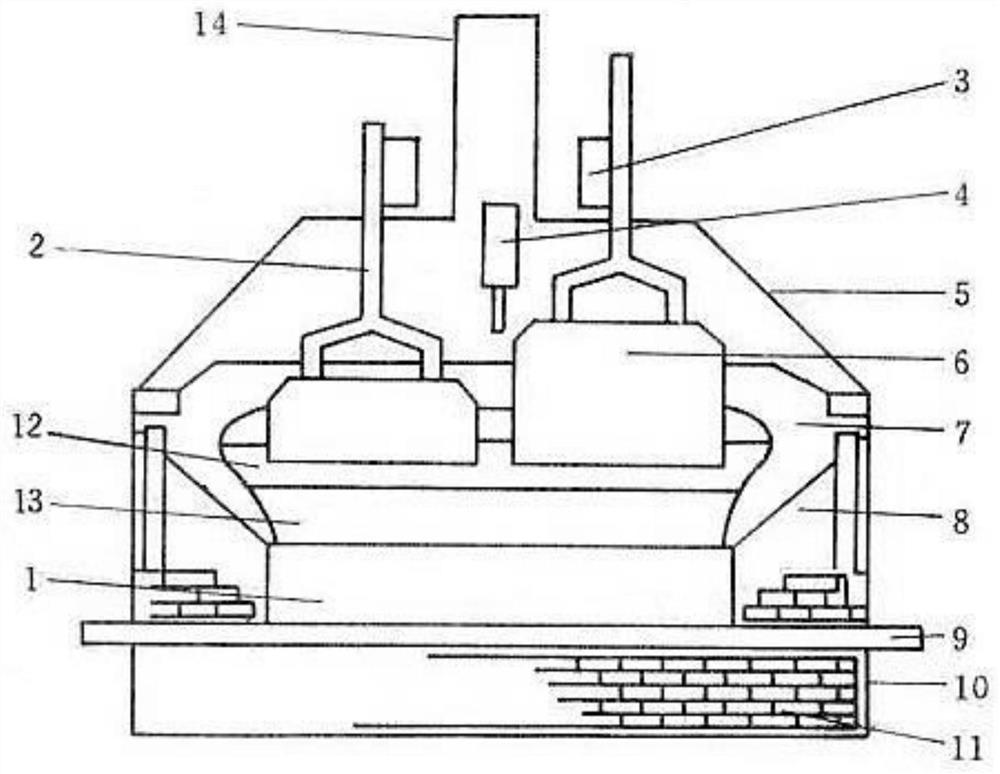

[0042] Such as Figure 4 The shown aluminum electrolytic cell system of the present invention includes: a cell body 100 and a heat exchange system, and the structure of the cell body 100 is the same as that of the aluminum electrolytic cell body in the prior art.

[0043] The heat exchange system is used to control the heat dissipation of the cell wall of the electrolytic cell, and can further realize the secondary utilization of the waste heat of the electrolytic cell. The heat exchange system includes a tank wall heat exchange device 31 , a flue gas heat exchange device (not shown in the figure), a flow regulating station 34 , a heat output device 35 , and a pipeline 36 . The cell wall heat exchange device 31 is arranged on the cell wall of the aluminum electrolytic cell, or is inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com