Fuel injector

A fuel injector and gaseous fuel technology, which is applied to fuel injection devices, special fuel injection devices, fuel injection valves driven by fluid pressure, etc. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

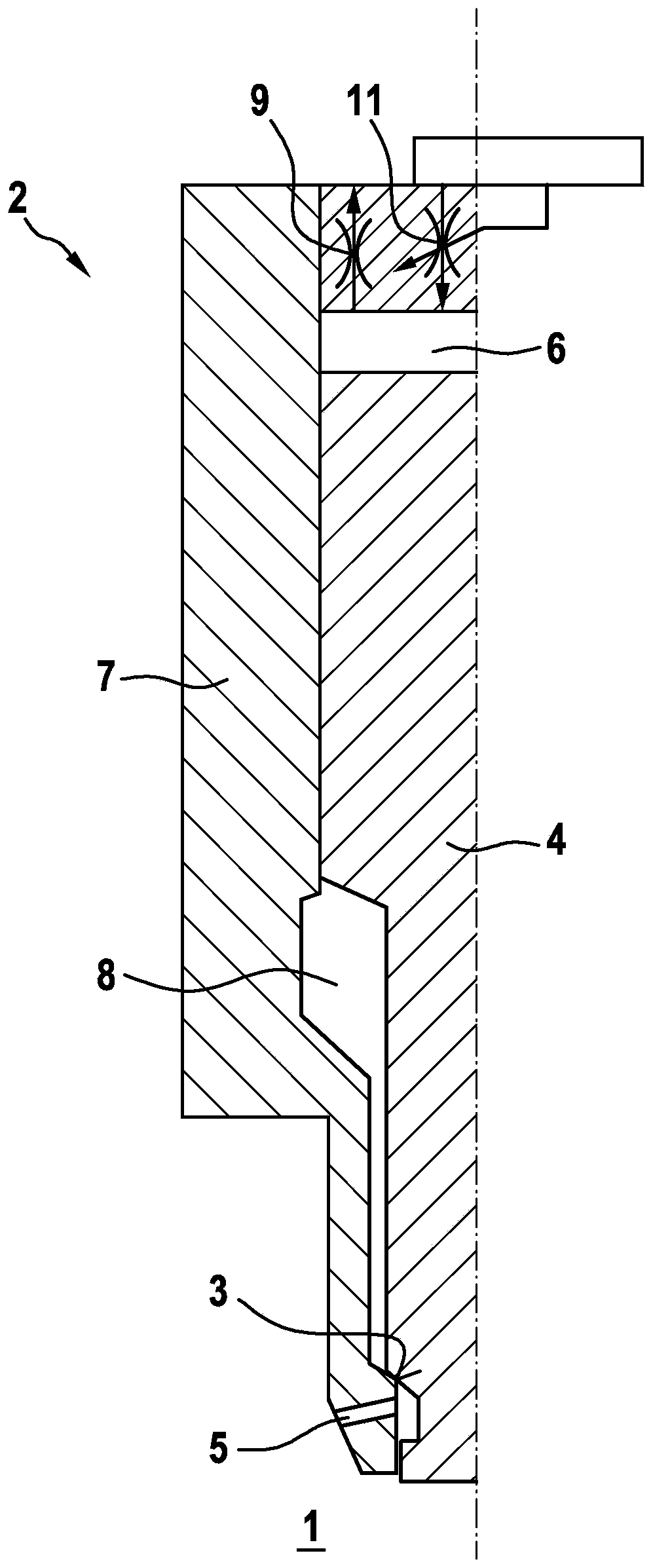

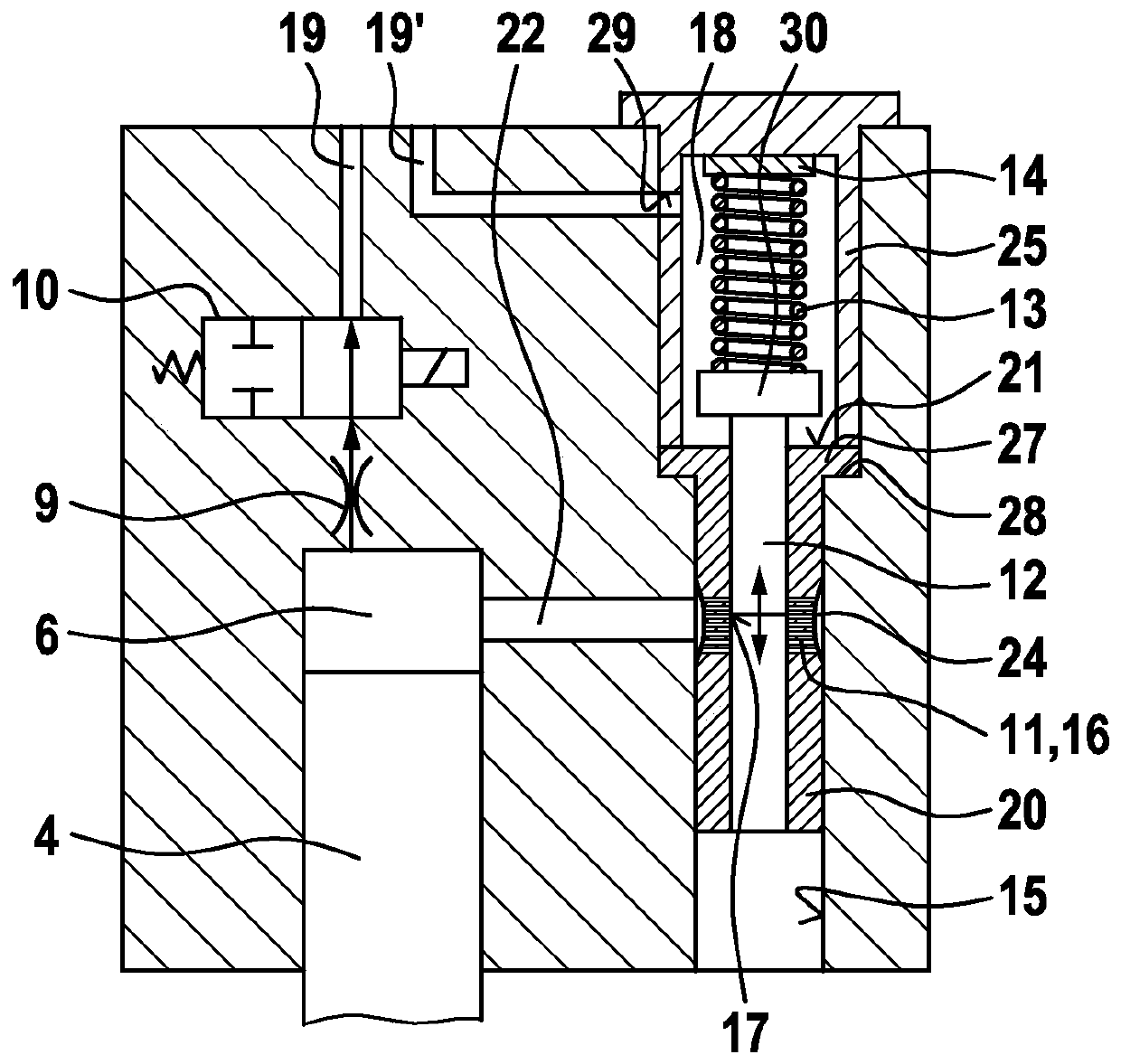

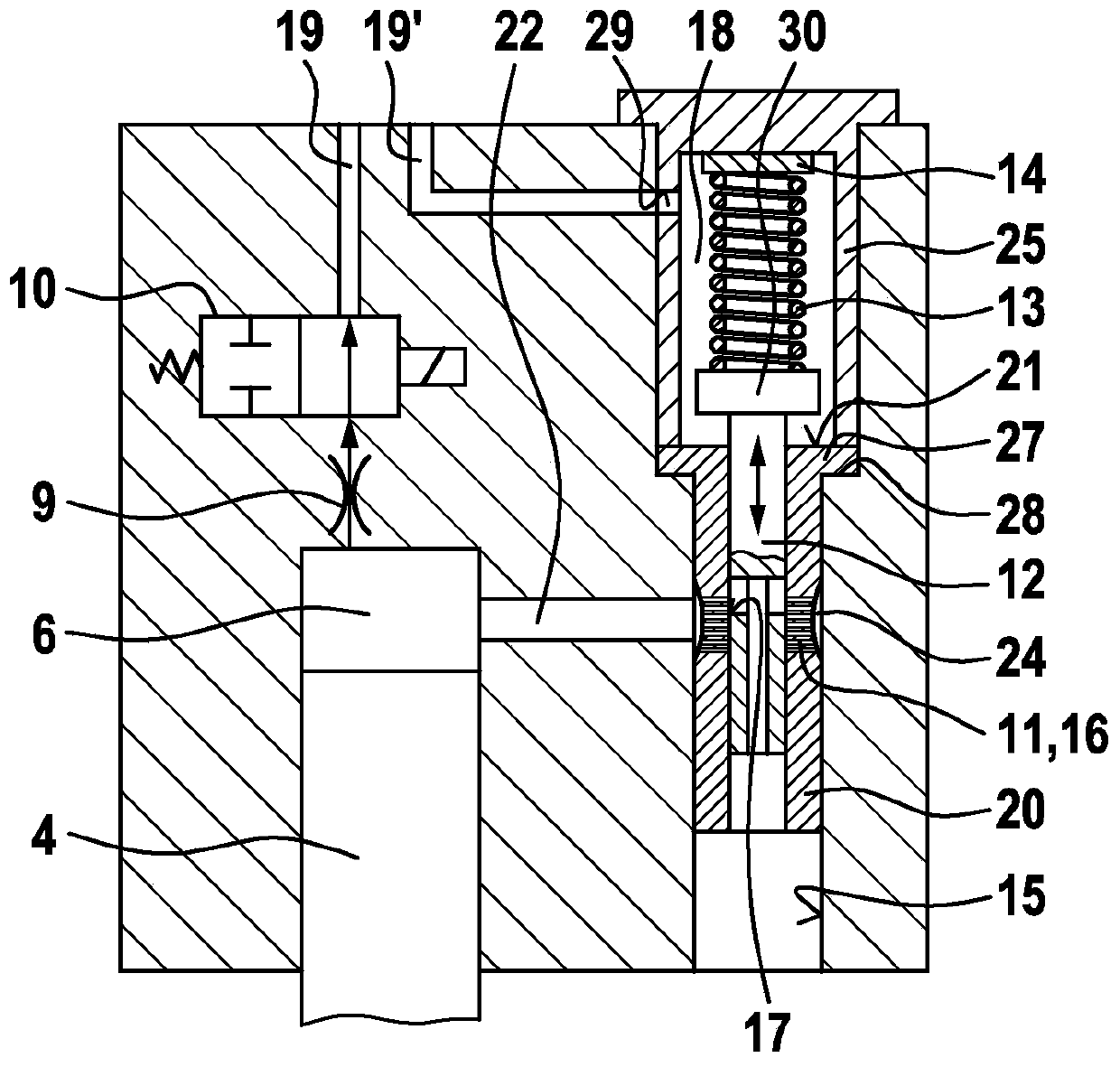

[0039] exist figure 1 The fuel injector 2 shown partially in the center comprises a nozzle body 7 which forms the sealing seat 3 for the reciprocating nozzle needle 4 . The blow-in opening 5 formed in the nozzle body 7 can be released or closed by the reciprocating movement of the nozzle needle 4 . With the nozzle needle 4 raised, gaseous fuel, for example natural gas, flows from the pressure chamber 8 formed between the nozzle body 7 and the nozzle needle 4 in the direction of the injection opening 5 and via the injection opening 5 to the Combustion chamber 1 of an internal combustion engine.

[0040] To open the nozzle needle 4 , the control pressure is reduced in the control chamber 6 above the nozzle needle 4 , which is acted upon by the hydraulic pressure medium. The control pressure acting on the nozzle needle 4 produces a hydraulic closing force which holds the nozzle needle 4 in the sealing seat 3 . For opening, the control pressure in the control chamber 6 is reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com