Reciprocating piston compressor for trans-critical CO2 refrigeration cycle

A refrigeration cycle, reciprocating piston technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., can solve the problems of small flow, high pressure, high pressure difference, etc., to improve reliability and improve suction volume efficiency , the effect of reducing the clearance volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

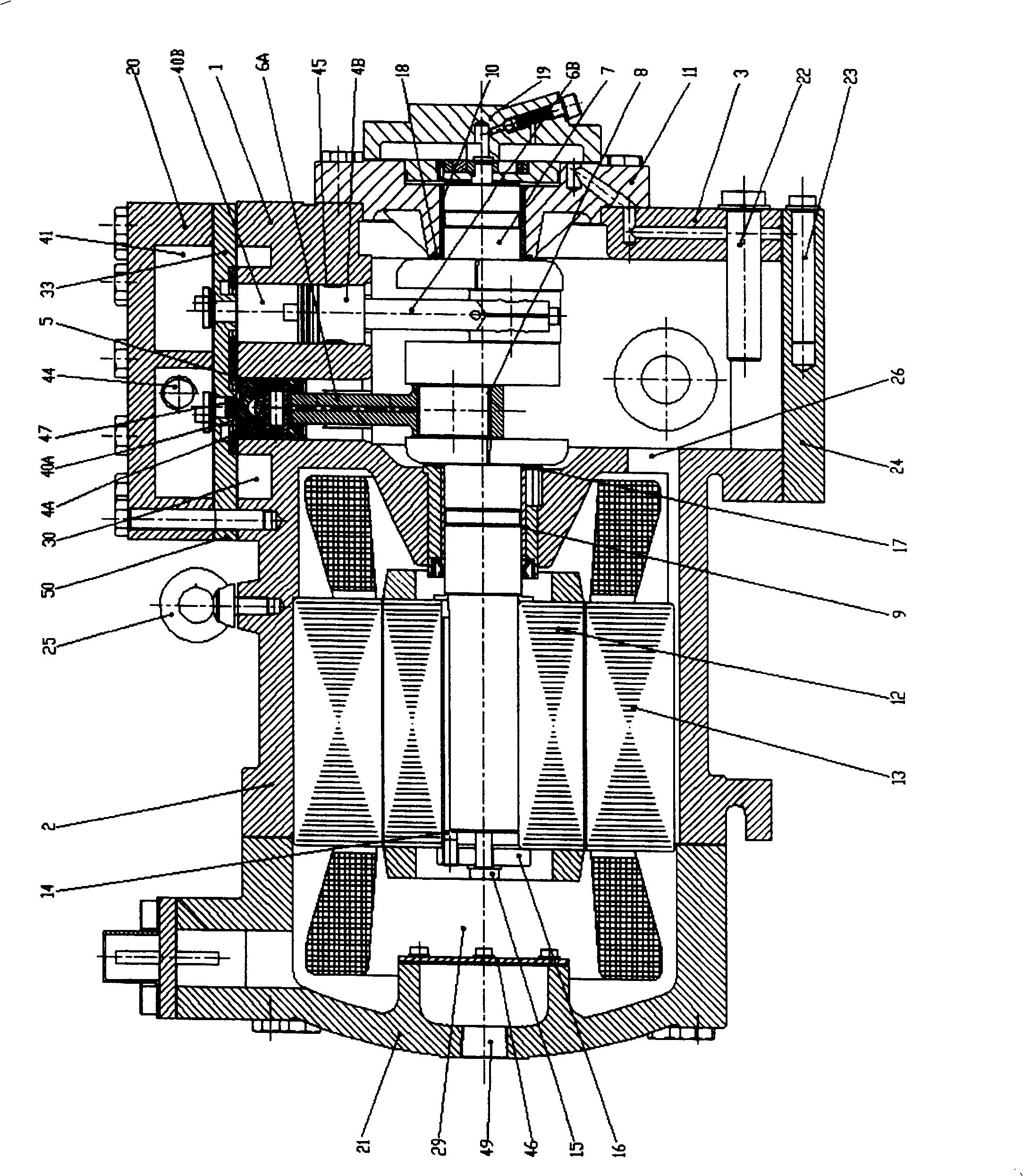

[0031] Referring to accompanying drawing, a kind of transcritical CO involved in the present invention 2 The compressor used in the refrigeration cycle is a semi-hermetic reciprocating piston type. The compressor housing is composed of cylinder block 1, motor housing 2 and crankcase 3. Cylinder block 1 and piston 4A and the top of piston 4B and valve plate assembly 50 constitute two sealed working cylinders 40A, 40B respectively, and the two working cylinders are vertical and parallel to each other, and their design parameters are the same; piston pin 5 connects two pistons 4A , 4B and connecting rods 6A, 6B are connected to form a connecting rod assembly, the crankshaft 7 is a 180 degree crankshaft, two connecting rods (6A and 6B) are connected to the crankshaft 7, and bearing bushes 8 (8A and 8B) are installed between them. Satisfy friction requirements. The crank shaft 7 is supported by the first and second sliding bearings 9 and 10, and is radially constrained on the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com