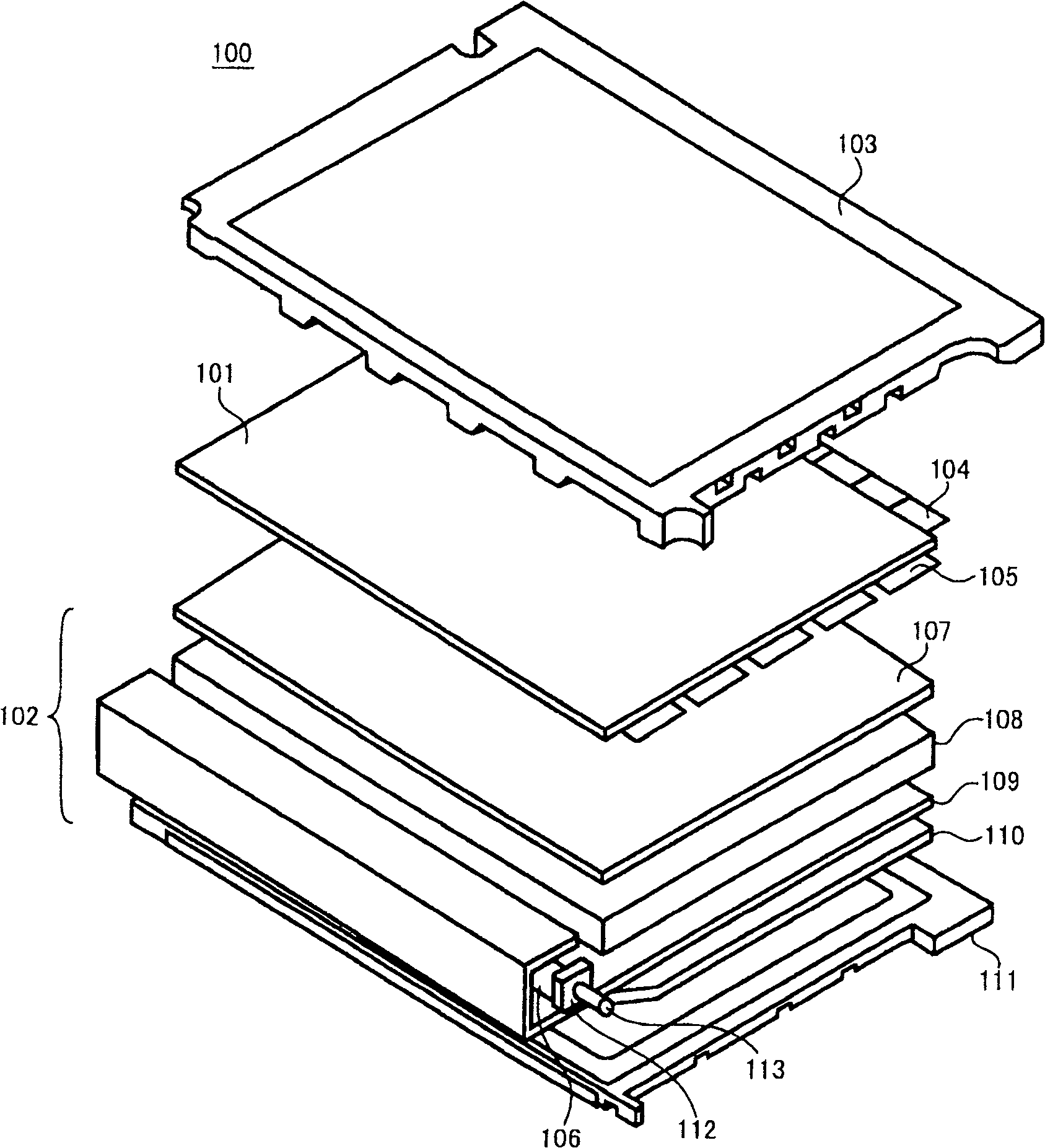

Planar light source and liquid crystal display device using the same

A technology for a liquid crystal display device and a light source device, applied in the fields of liquid crystal display devices and surface light source devices, can solve the problems of overheating, shortened life of the linear light source, inappropriate heat distribution of the linear light source, etc. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

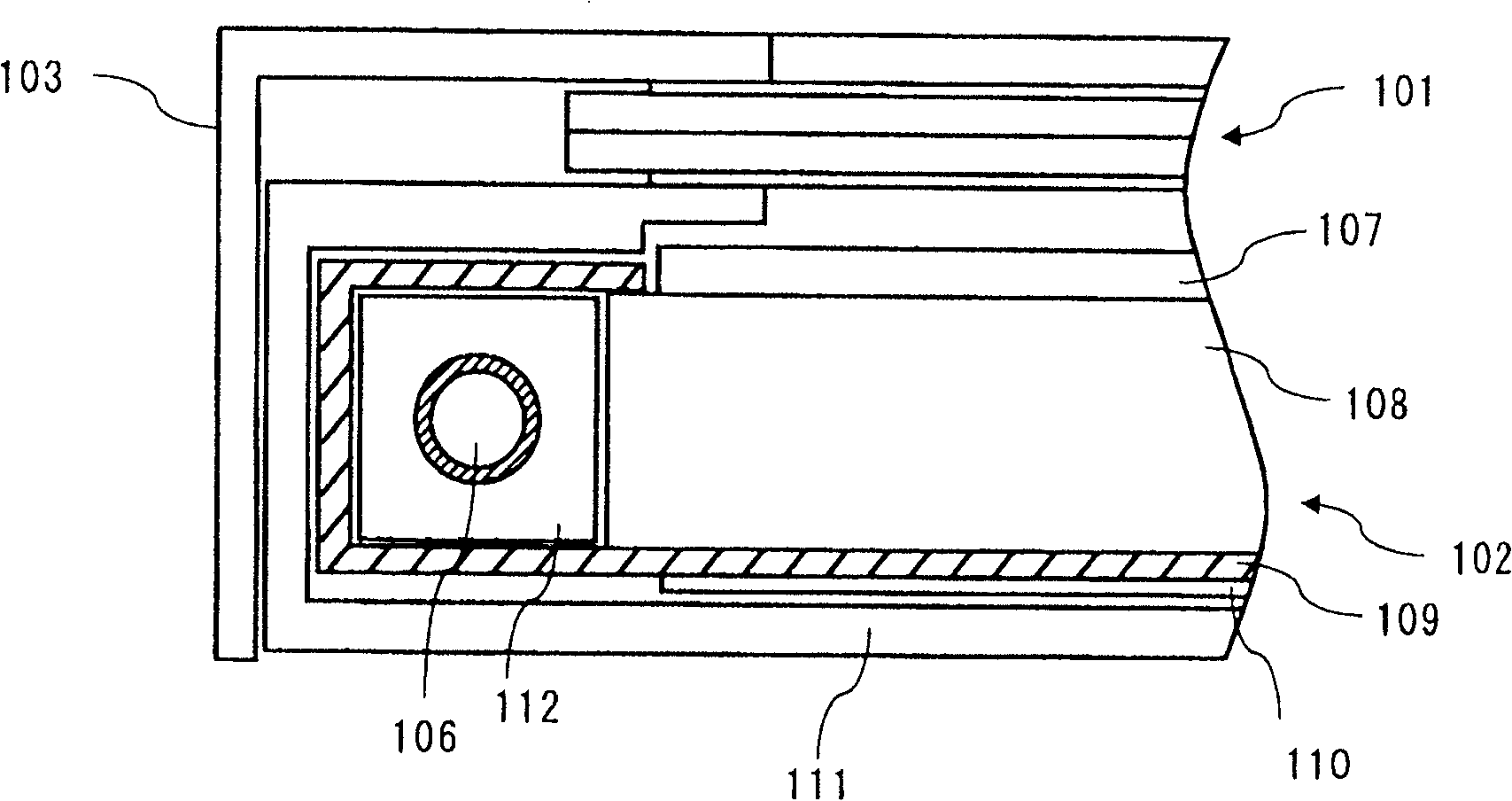

[0044] refer to Figure 4 Example 2 of the present invention will be described. Figure 4 It is a front view for explaining the arrangement relationship of each constituent element of the backlight unit 102 of the second embodiment. Figure 4 Only a few elements are shown for simplicity of illustration. Figure 4 The same symbol is used in the Figure 1~3 The same constituent elements in , and repeated descriptions are omitted.

Embodiment 1

[0045] In Embodiment 1, the end of the vapor chamber 110 spans the entire area facing the linear light source 106 including the electrode portion 114 , and is farther away from the linear light source than the incident side of the light guide plate 108 . In this case, the original purpose of using the vapor chamber 110, that is, the luminous heat of the linear light source 106, or the heat soaking effect of the driving circuit components such as the source driver 104 and the gate driver 105 is reduced, and the occurrence of A case where the degree of unevenness worsens is shown. In addition, due to insufficient heat soaking of the liquid crystal display panel 101 , display unevenness occurs around the panel, and particularly, display unevenness easily occurs near the center of the edge of the panel.

[0046] For this reason, in this embodiment, as Figure 4 As shown, within the range of the position of the linear light source 106, except for the position determining portion 1...

Embodiment 3

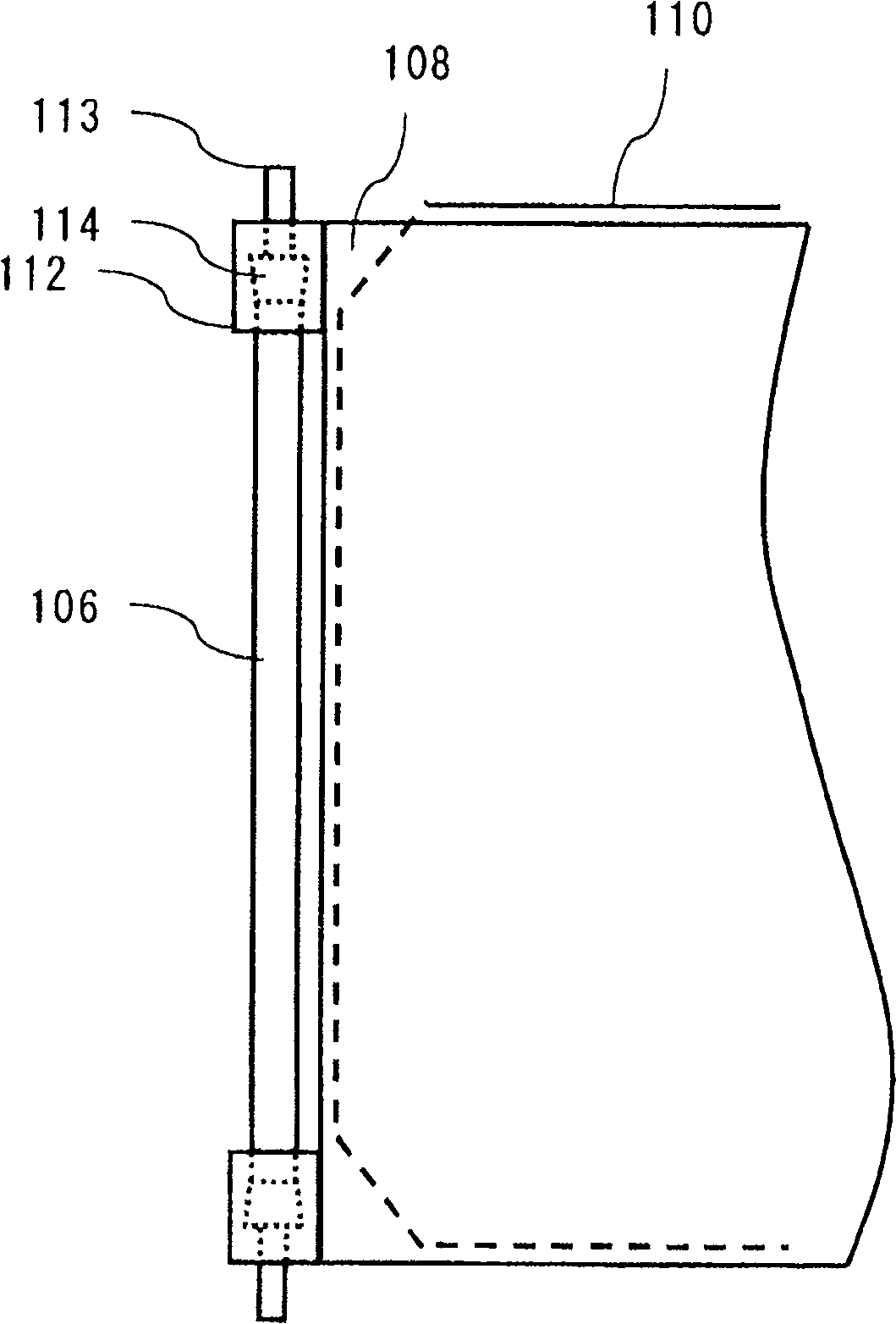

[0054] refer to Figure 5 Embodiment 3 of the present invention will be described. Figure 5 It is a front view for explaining the arrangement relationship of each constituent element of the backlight unit 102 of the third embodiment. Figure 5 Only a few elements are shown for simplicity of illustration. Figure 5 The same symbol is used in the Figure 1-3 The same constituent elements in , and repeated descriptions are omitted.

[0055] In this embodiment, the linear light source 106 is a cold cathode tube formed by bending more than once. That is, the linear light source 106 in this embodiment has one or more bent portions. Here, if Figure 5As shown, the linear light source 106 is a U-shaped cold-cathode tube with two bending points obtained by two bending processes. However, the shape of the linear light source 106 is not limited thereto, and an L-shaped light source having one bending point formed by a single bending process may be used. The electrode portion 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com