Method and apparatus for producing rod shape article with synthetic resin

A technology of synthetic resin and manufacturing method, applied in the direction of fiber mechanical structure, etc., can solve the problems of reduced shape and dimensional accuracy of synthetic resin liner layer, high product loss, and unstable winding tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

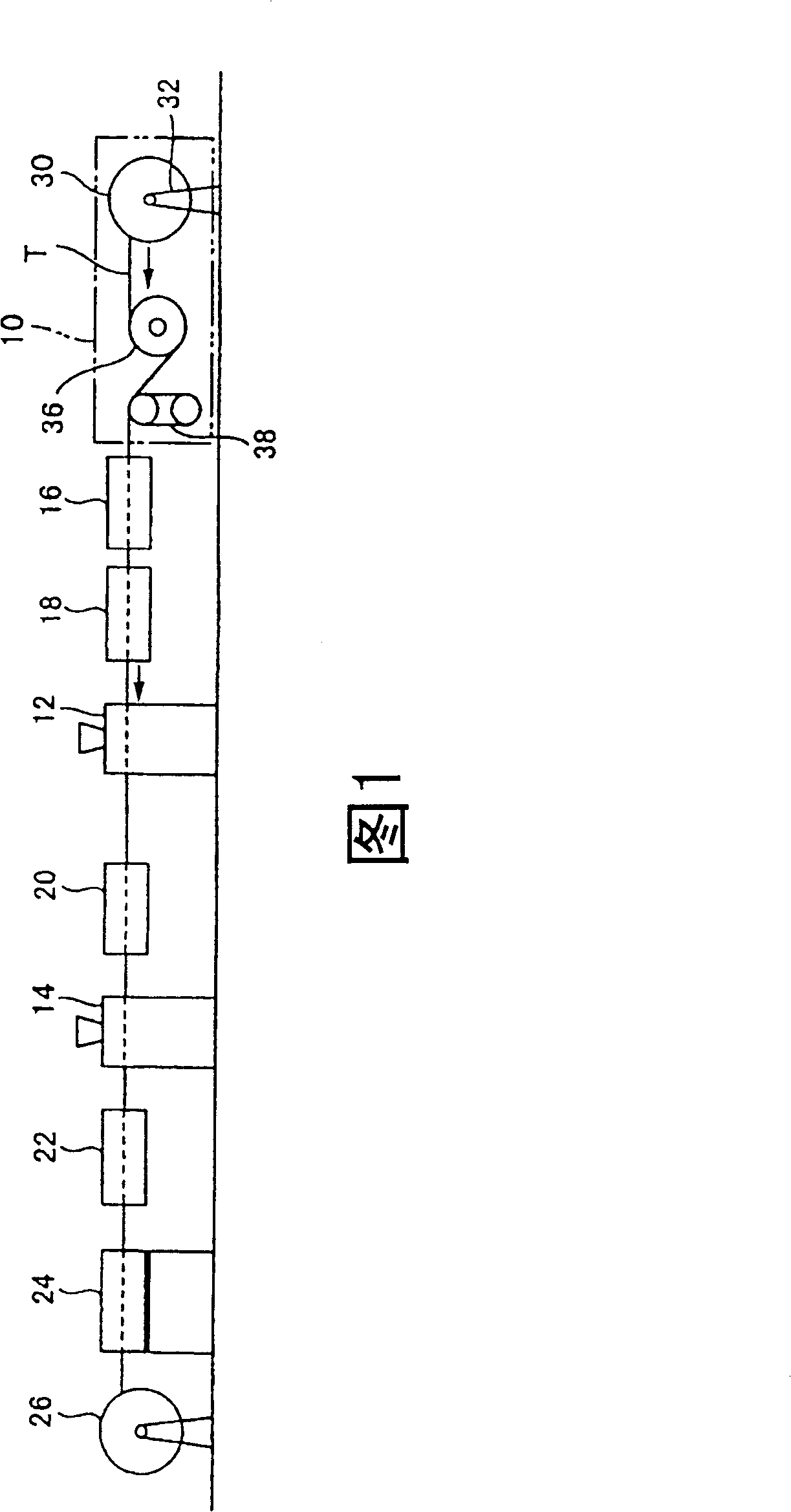

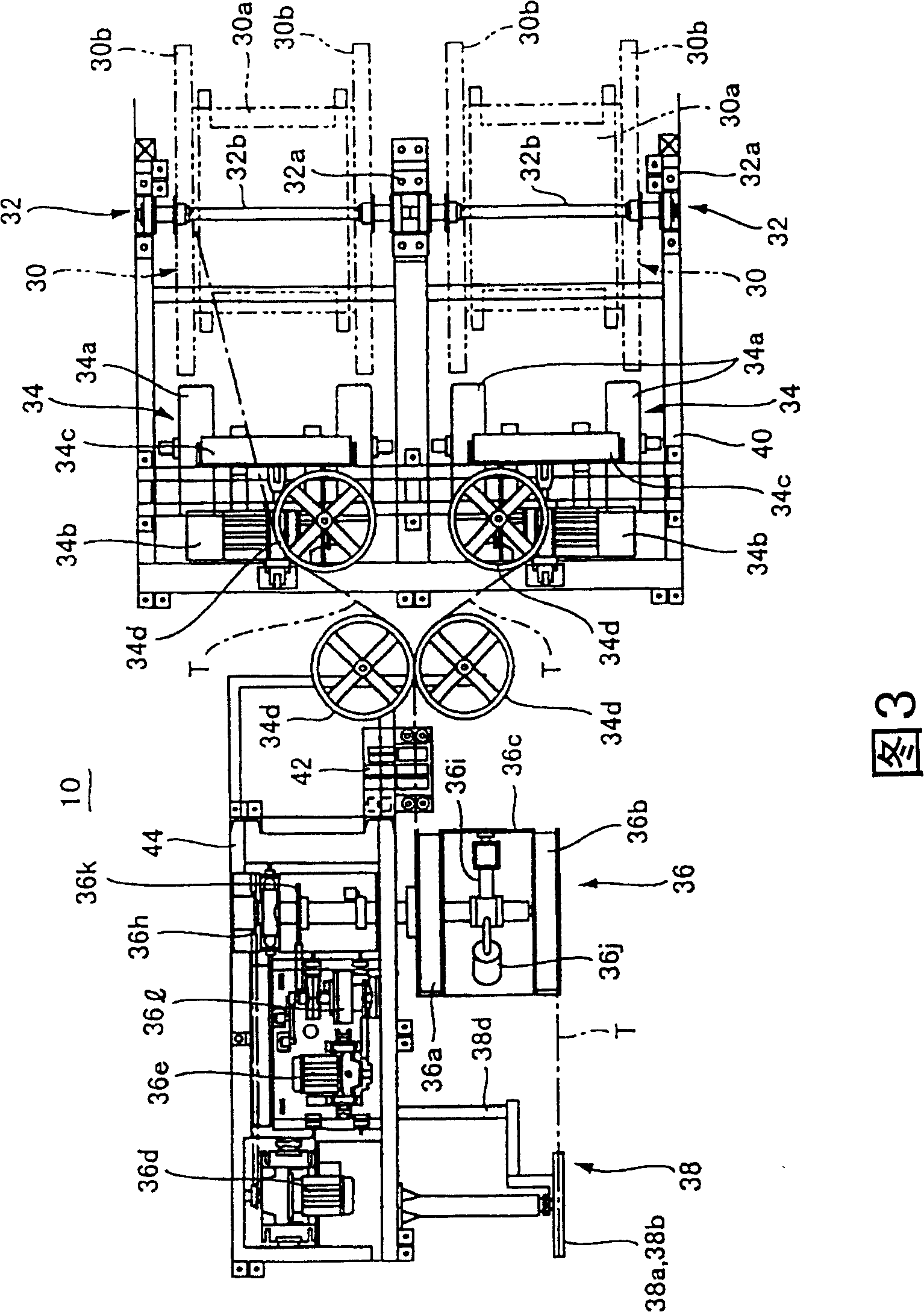

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings. Figure 1~ Figure 7 It shows an example of the manufacturing method and manufacturing apparatus of the synthetic resin stick-shaped object of this invention.

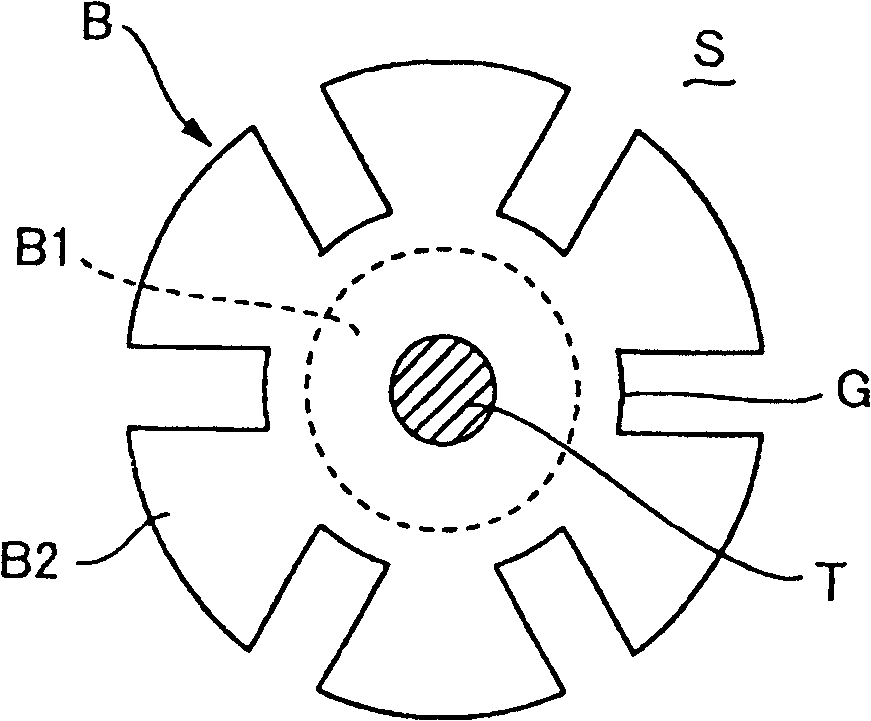

[0030] The manufacturing method and manufacturing apparatus shown in these figures illustrate the case where the present invention is applied to the manufacture of the fiber-carrying screw bushing S which is a synthetic resin rod. Such as figure 2 As shown in the middle cross-section, the spiral bushing S includes a tension-resistant body T disposed in the center and a body B formed by coating on its outer periphery. In the body B, a plurality of spiral grooves G are formed.

[0031] When manufacturing the spiral bushing S having such a structure, the tensile body T is fed out from the feeding device 10, the tensile body travels at a predetermined speed, and the body B is formed by continuously extrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com