ROPS canopy of hydraulic shovel

An excavator and roof technology, which is applied to the superstructure, vehicle safety arrangement, superstructure and other directions of trucks, can solve the problems of high production cost, increased inventory management cost, and increased total ROPS inventory, and achieves The effect of preventing the reduction of working time and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

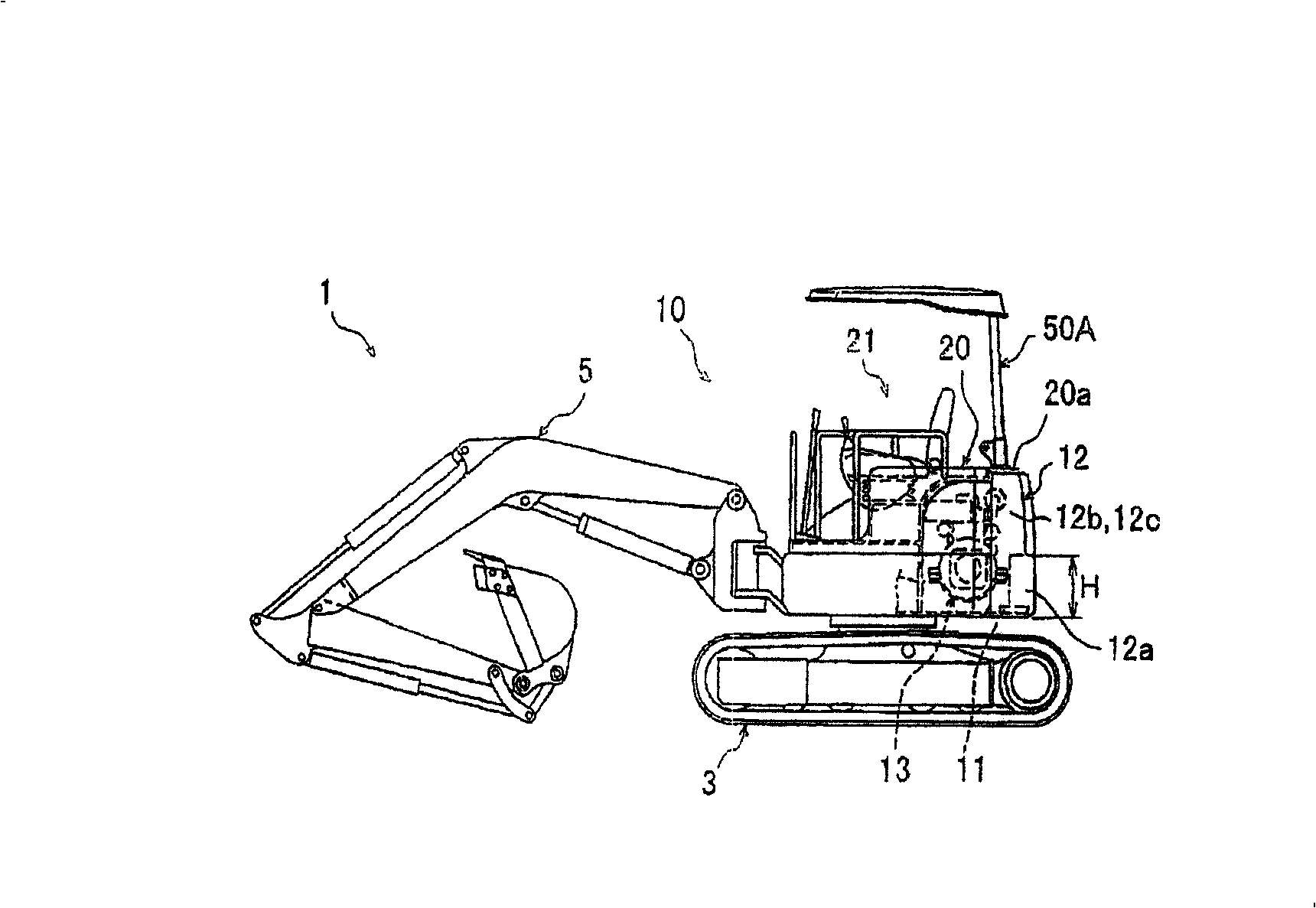

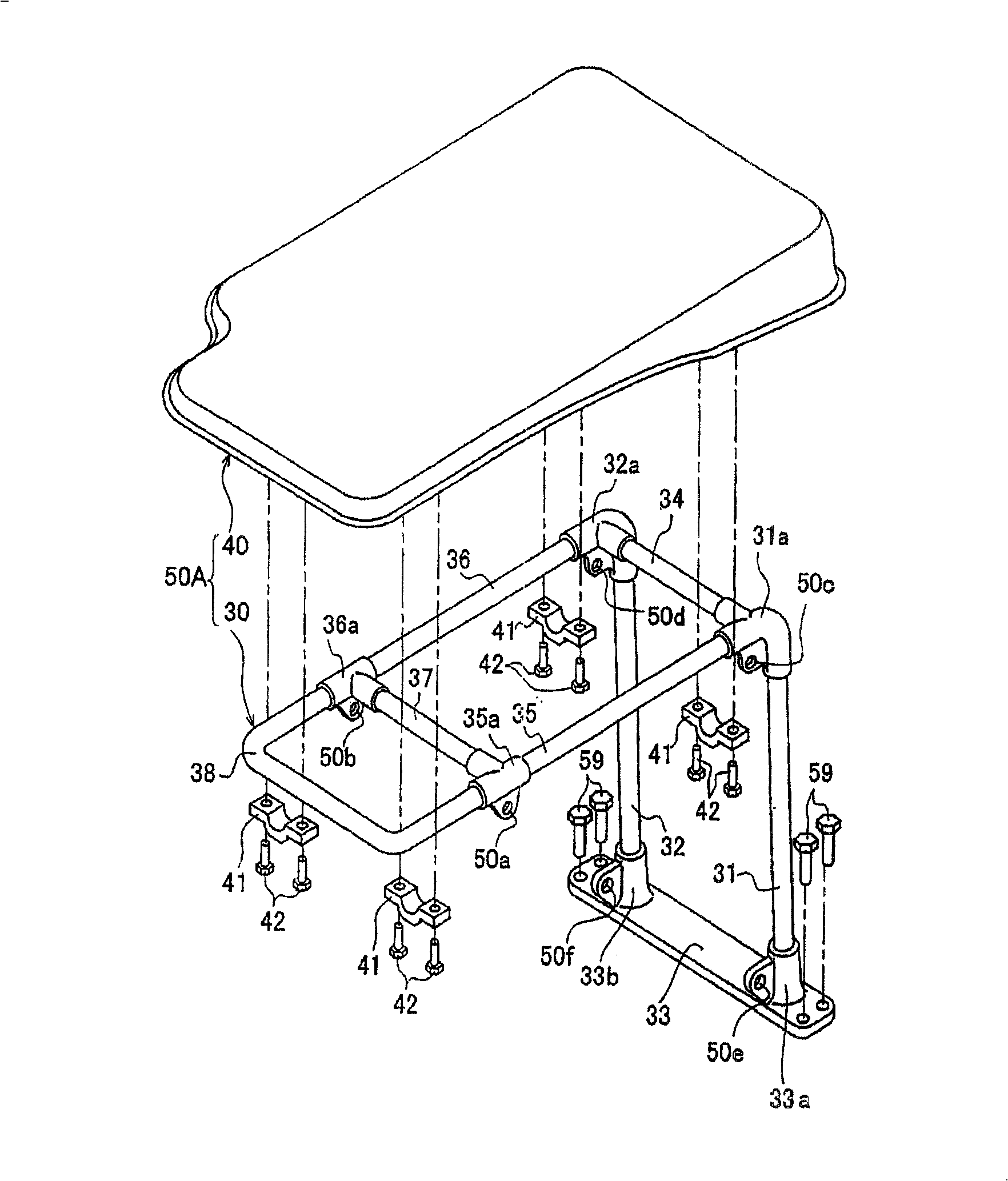

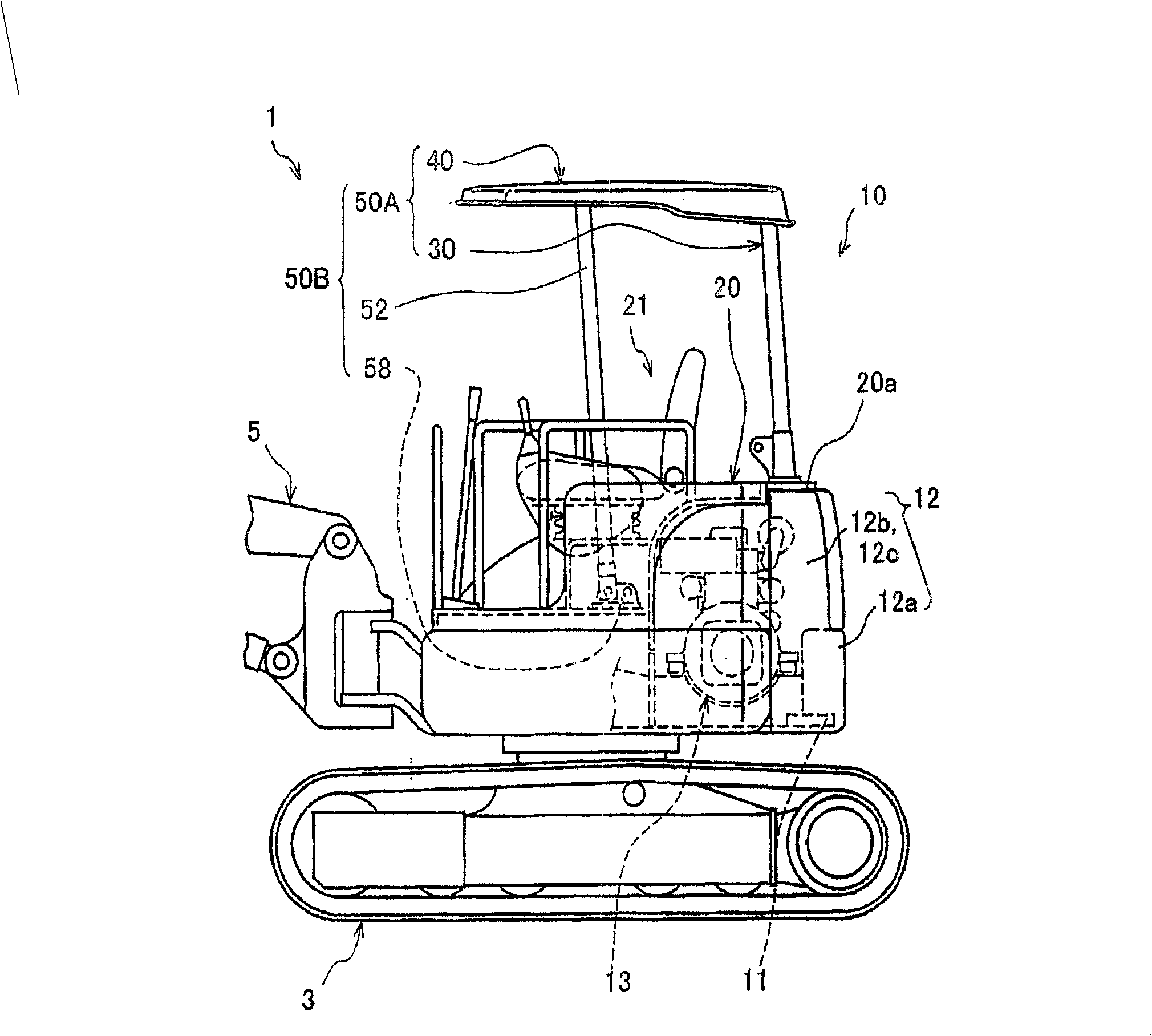

[0027] Below, refer to Figure 1 to Figure 10 , the embodiment of the ROPS roof of the hydraulic excavator of the present invention will be described in detail.

[0028] First, according to figure 1 , figure 2 The first embodiment will be described. figure 1 It is a side view of the hydraulic excavator to which the ROPS roof of the first embodiment is applied, figure 2 It is a perspective view showing the structure of the ROPS top cover of 1st Embodiment. In addition, the same code|symbol is attached|subjected to the component which has substantially the same function as the component described in the drawing mentioned above, and the following description is abbreviate|omitted, and the same applies hereafter.

[0029] Figure 1 ~ Figure 2 In the hydraulic excavator 1, an upper revolving body 10 is mounted on the upper part of the lower mobile body 3 to be able to turn freely. Balanced with the working machine 5 , counterweights 12 are arranged at the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com