Device for producing special yarn

A yarn manufacturing, special technology, applied in the field of special yarn manufacturing equipment, which can solve problems such as inability to guarantee reproducibility, inability to produce yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

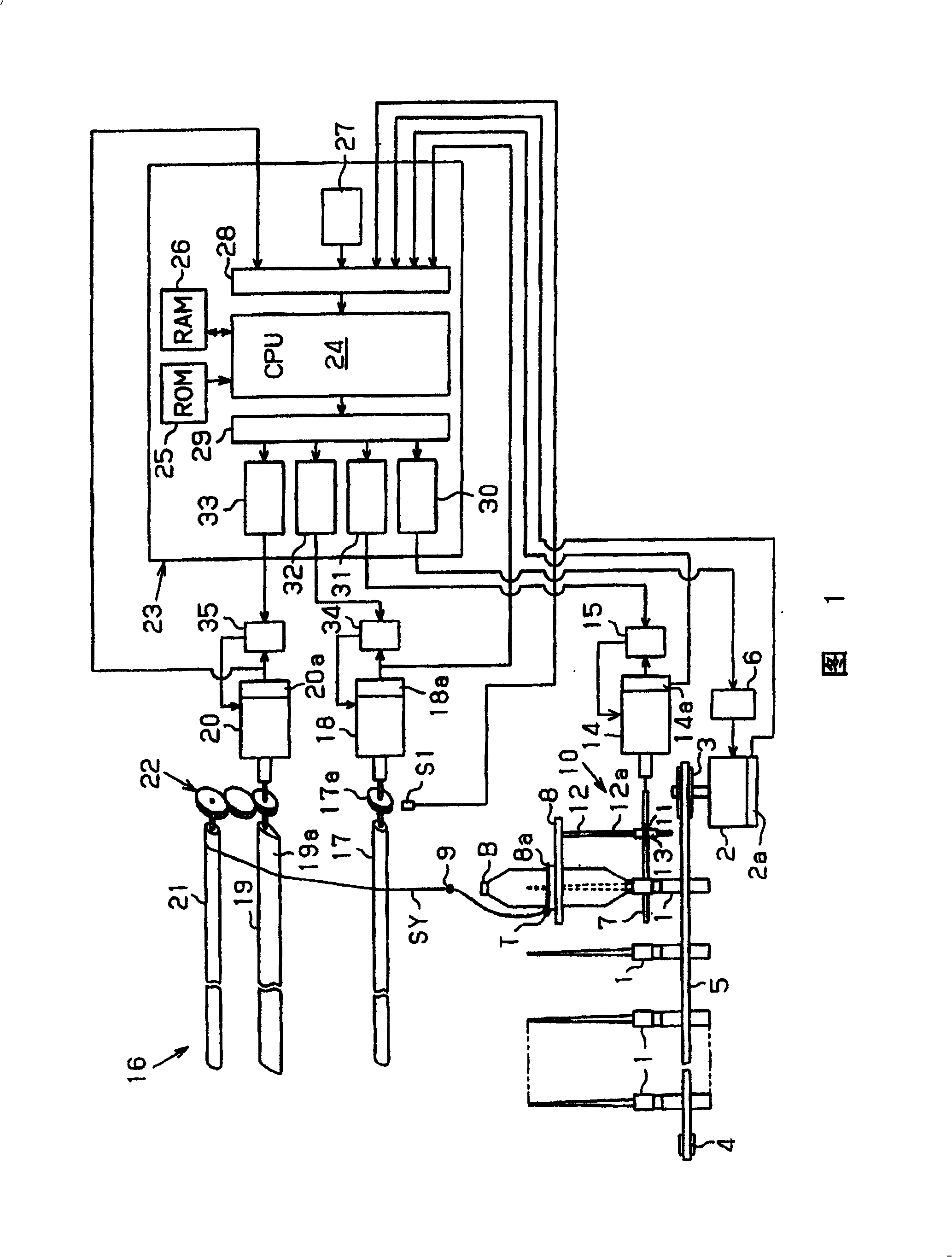

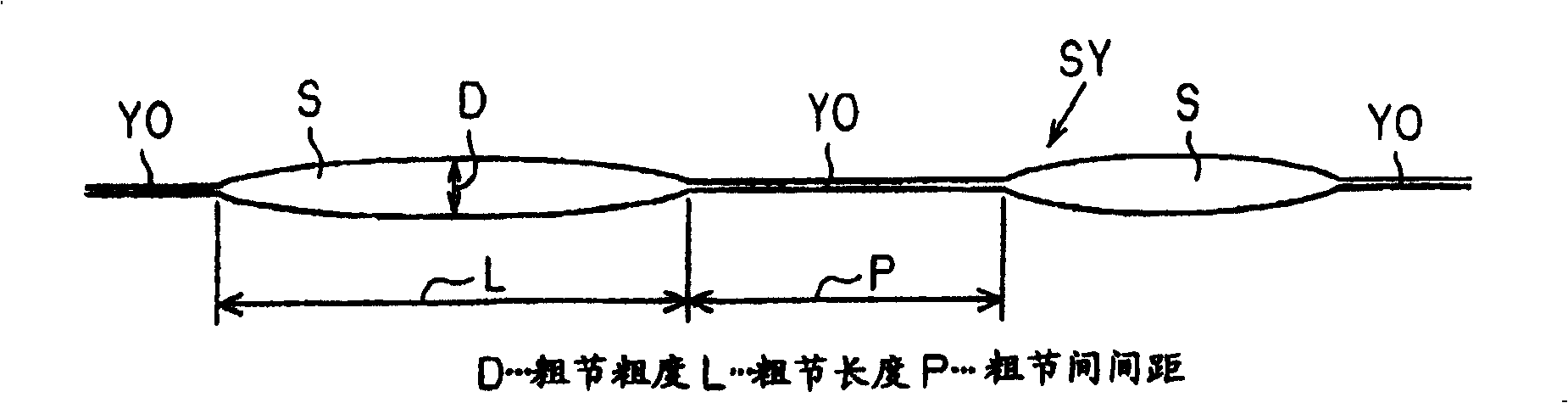

[0012] Next, according to Figure 1 to image 3 A first embodiment will be described which embodies the present invention as a special yarn manufacturing apparatus that forms slubs by shifting the front rollers. Figure 1 is a block diagram of a special yarn manufacturing device, figure 2 It is a partial schematic diagram of a special yarn.

[0013] The special yarn making unit is basically the same as the ring spinning machine. As shown in FIG. 1 , the spindle 1 is driven to rotate by a spindle drive system, which includes: a drive pulley 3 driven by a motor 2 , a driven pulley 4 , and a tangential transmission belt wound between the two pulleys 3 and 4 5. As the motor 2, a variable-speed motor driven via an inverter 6 is used, and has a rotary encoder 2a. The main shaft 7 is rotatably arranged along the spindle row. Elevating assemblies 10 (only one shown in the figure) are arranged on the main shaft 7 at predetermined intervals, and the elevating assemblies 10 connect a ...

no. 2 approach

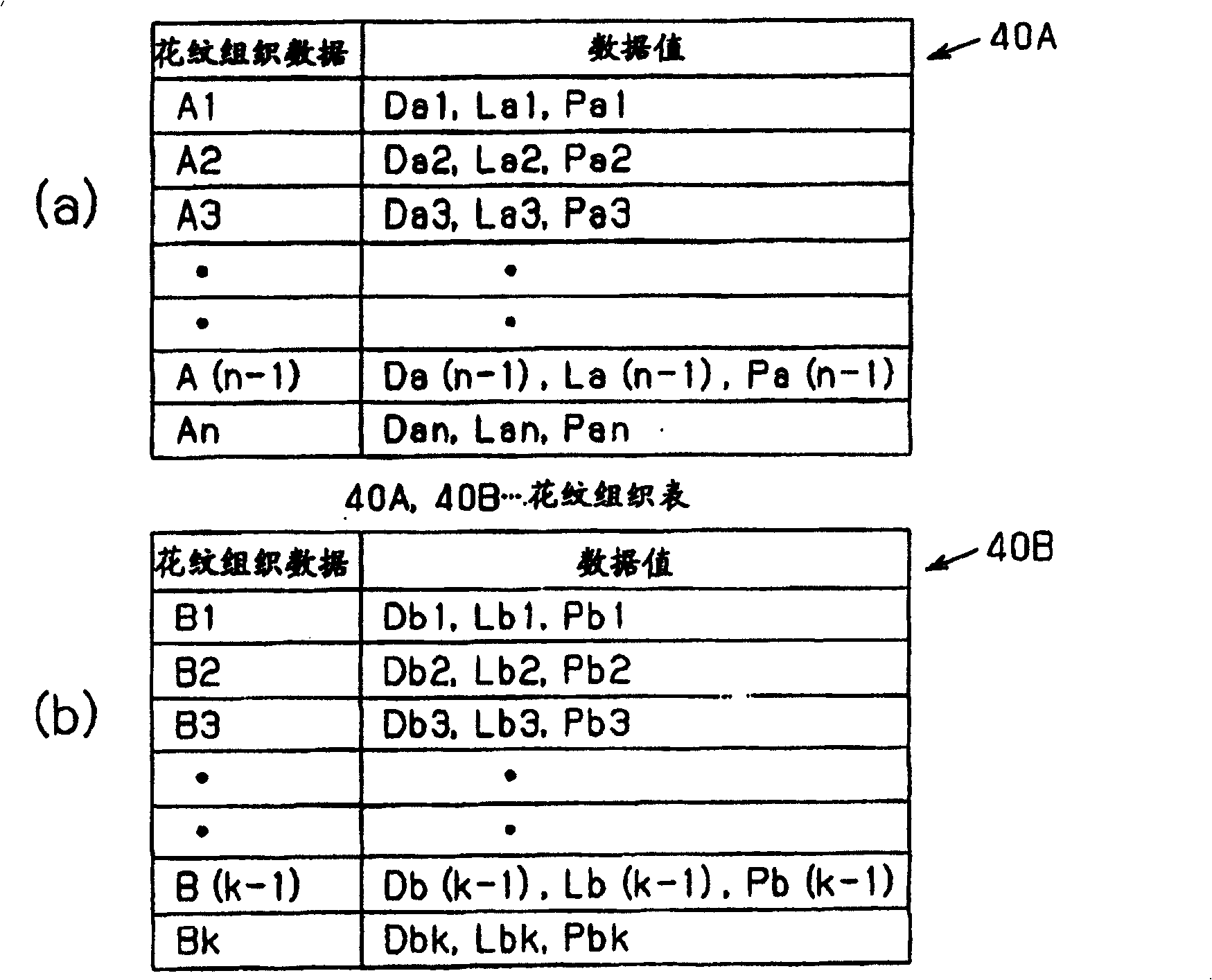

[0045] Next, the second embodiment will be described. In this embodiment, the CPU 24 decides to read out the pattern weave data A1, A2...A(n-1), An and the pattern weave data B1, B2...B( It differs from the above-described first embodiment in that the order of k-1) and Bk is different, and the number of pattern weave data in the pattern weave tables 40A and 40B can be the same. The other structures are the same as those of the above-described first embodiment, and the same components as those of the first embodiment are denoted by the same reference numerals, and the description thereof will be omitted or abbreviated.

[0046] In this embodiment, when the number of pattern weave data in each of the pattern weave tables 40A and 40B is different, each pattern weave data is sequentially and alternately read from each of the pattern weave tables 40A and 40B according to the same rules as in the first embodiment. A1, A2...A(n-1), An and pattern structure data B1, B2...B(k-1), Bk. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com