Tower bubbling stuffing with vortex-flow and defrosting function

A functional and column technology, applied in the field of petrochemical column packing and mist eliminators, which can solve problems such as coupling of unseen mass transfer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

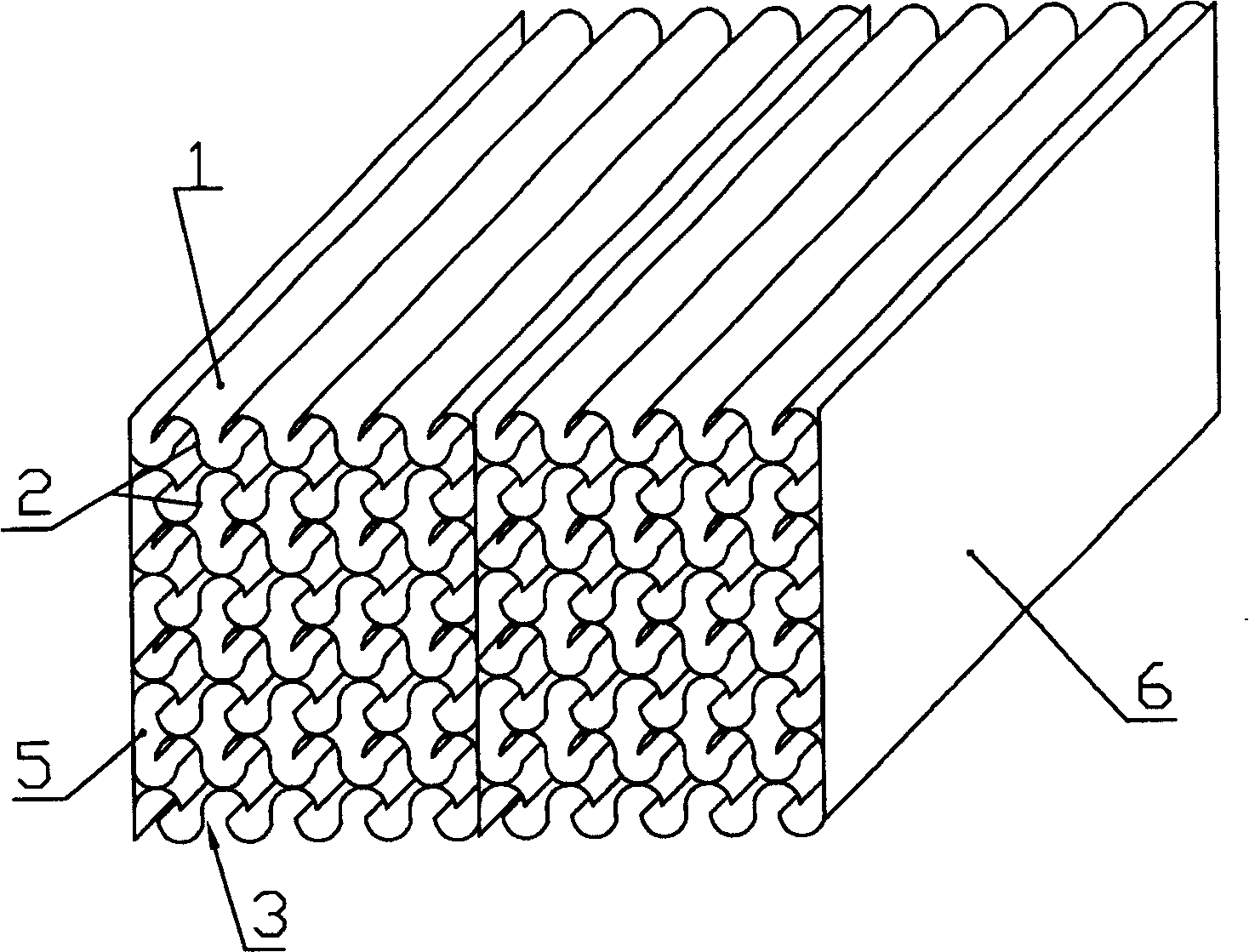

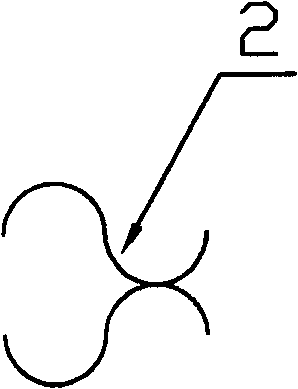

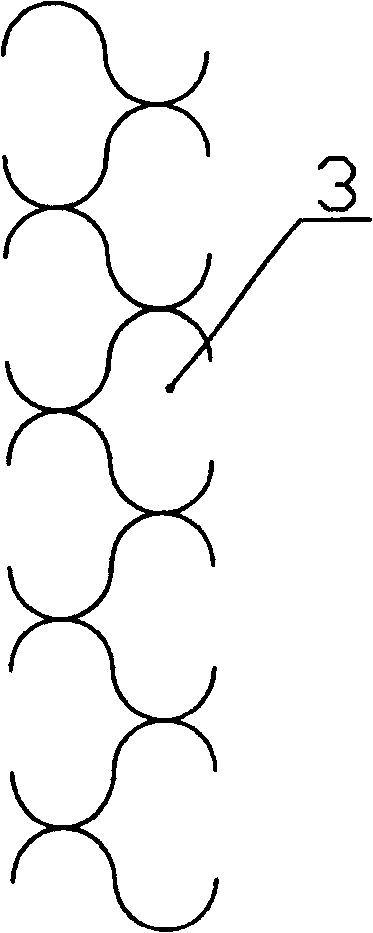

[0025] See figure 1 , It includes an S-shaped wave plate 1, the S-shaped wave plate is butted in opposite directions to form a packing unit 2, such as figure 2 As shown, a plurality of the packing units 2 are arranged longitudinally to form a packing unit row 3, such as image 3 Shown; see Figure 4 , A plurality of the packing unit rows are arranged horizontally and parallel to form a packing block 4, and the packing unit rows and the rows are partially overlapped, so that the butt closed end of the front packing unit extends into the C-shaped open end of the rear packing unit. There are half packing unit row sealing plates 5 and 6 on both sides of multiple packing unit rows, thus forming such figure 1 A completed structured packing shown.

[0026] Refer to Figure 5, when the sprayed liquid enters the packing, a part of the liquid will be temporarily stored in the semicircular groove 1-1 of each S-shaped wave plate, and the semicircle on the semicircular groove 1-1 is reversed...

Embodiment 2

[0028] The structure equivalent to the structure of the above example is: see Figures 6 and 7, it includes a perpendicularly bent right-angled S-shaped plate, the right-angled S-shaped plate is butted in opposite directions to form a packing unit (8-1), multiple The packing units (8-1) are arranged longitudinally to form a packing unit row (8), and a plurality of the packing unit rows 8 are arranged in parallel to form a packing block (7), and there is a partial overlap between the packing unit rows and the rows. The butt closed end of the front packing unit extends into the C-shaped open end of the rear packing unit, and half packing unit sealing plates 9 and 10 are arranged on both sides of the packing block 7 to form a complete structured packing.

[0029] The installation structure of the packing (including the packing described in Example 1 and Example 2) in the tower is shown in Figure 8 and Figure 10. When the tower diameter is small, the packing 11 can be directly placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com