Tower bubbling stuffing with vortex-flow and defrosting function

A function and tower technology, applied in the field of petrochemical tower packing and mist eliminator, can solve problems such as mass transfer process coupling that has not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

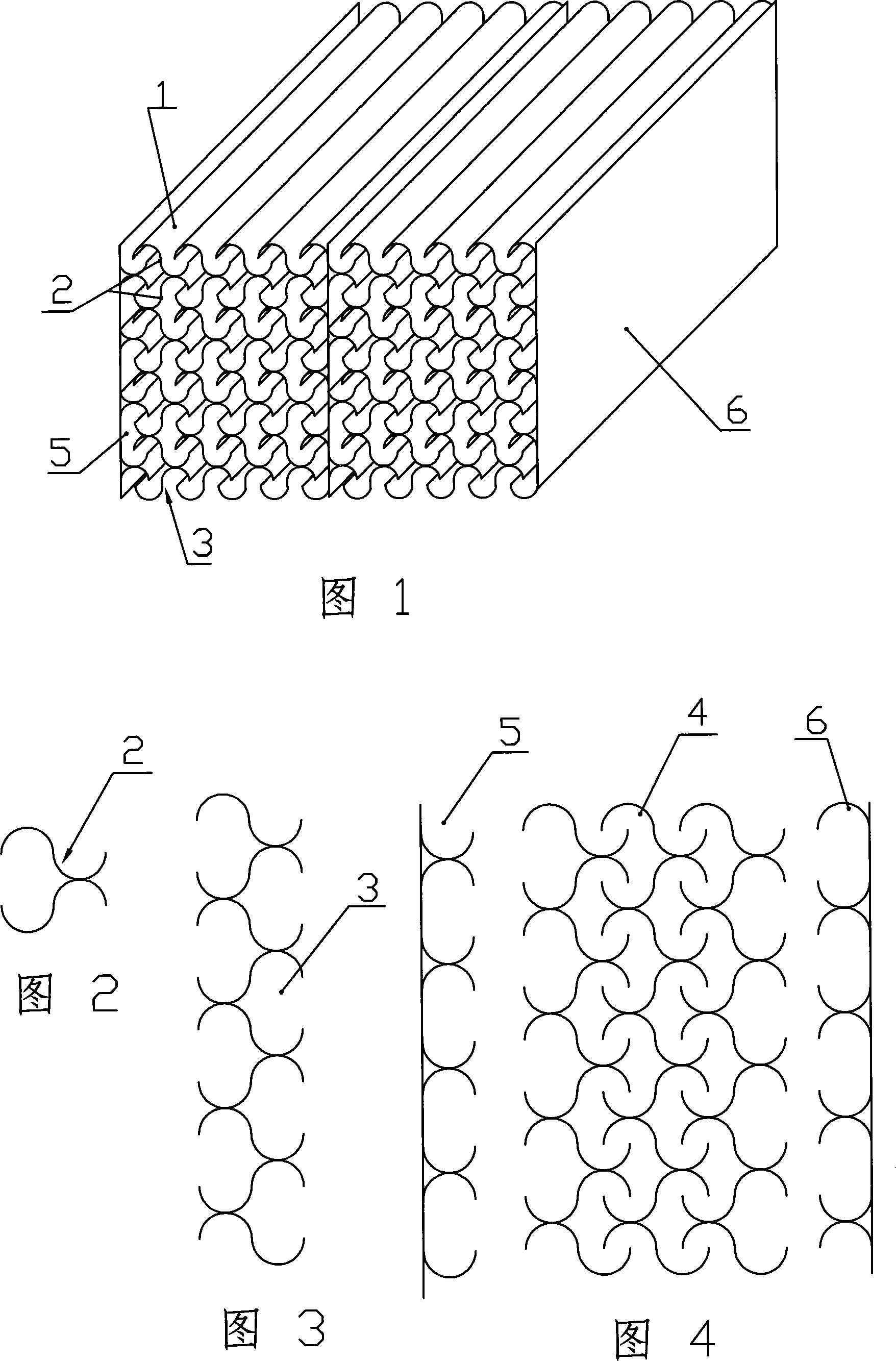

[0025] Referring to Fig. 1, it includes an S-shaped corrugated plate 1, and the S-shaped corrugated plates are oppositely connected in pairs to form a packing unit 2, as shown in Fig. 2, a plurality of such packing units 2 are vertically arranged to form a packing unit column 3, As shown in Figure 3; see Figure 4, a plurality of the packing unit rows are arranged in parallel to form a packing block 4, and the packing unit rows partially overlap each other, so that the butt closed end of the front packing unit extends into the rear packing In the C-shaped opening end of the unit, half packing unit row sealing plates 5 and 6 are provided on both sides of multiple packing unit rows, thereby forming a completed structured packing as shown in FIG. 1 .

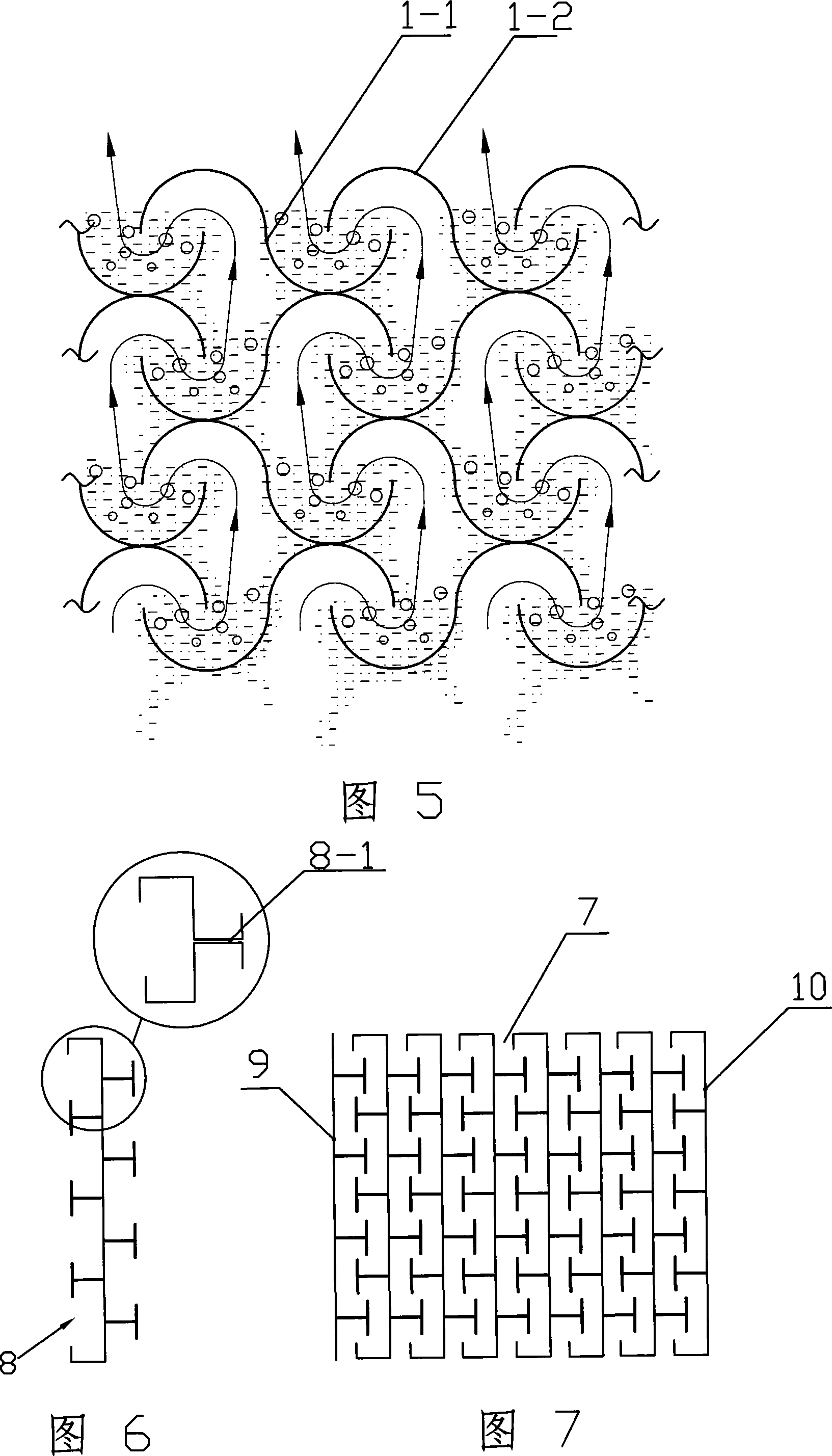

[0026] Referring to Figure 5, when the sprayed liquid enters the filler, a part of the liquid will be temporarily stored in the semicircular groove 1-1 of each S-shaped wave plate, and the reversed semicircle on the semicircular groo...

Embodiment 2

[0028] The structure equivalent to the structure effect of the previous example is: see Figures 6 and 7, it includes a vertically bent right-angled S-shaped plate, the right-angled S-shaped plate is oppositely connected in pairs to form a packing unit (8-1), and a plurality of The packing units (8-1) are arranged longitudinally to form a packing unit row (8), and a plurality of the packing unit rows 8 are arranged in parallel horizontally to form a packing block (7), and there is a partial overlap between the packing unit rows, Make the butt joint closed end of the packing unit in the front row extend into the C-shaped opening end of the packing unit in the rear row, and set half packing unit sealing plates 9, 10 on both sides of the packing block 7, thereby forming a complete structured packing.

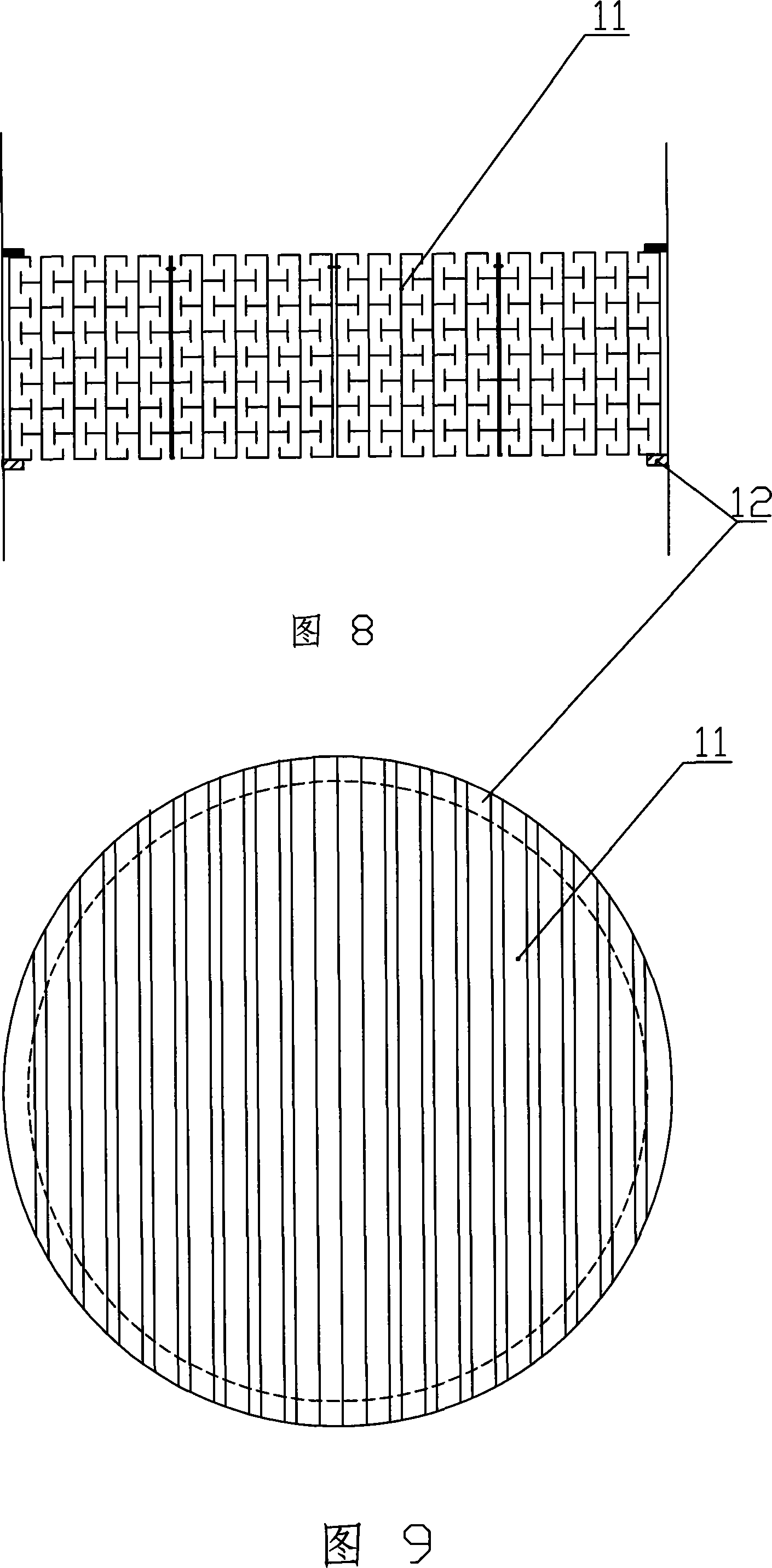

[0029] The installation structure of the packing (comprising the packing described in embodiment 1 and embodiment 2) in the tower is shown in Figure 8 and Figure 10, when the tower d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com