Dispersion detecting device of amount of suction air

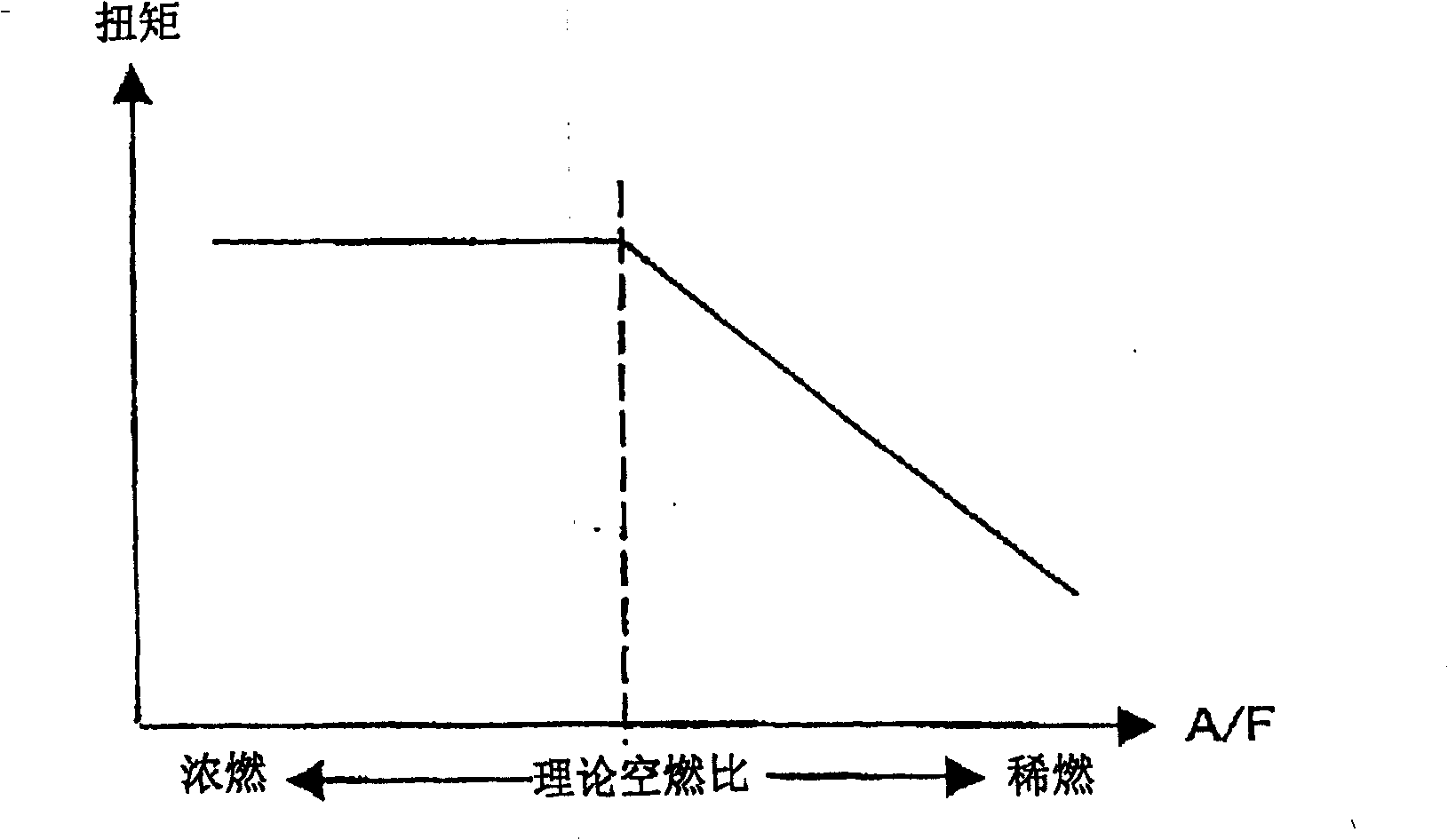

A technology for detection of intake air volume and deviation, applied in electrical control, machine/engine, output power, etc., to solve problems such as deterioration of exhaust emissions, torque fluctuations of internal combustion engines, deviation of intake air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

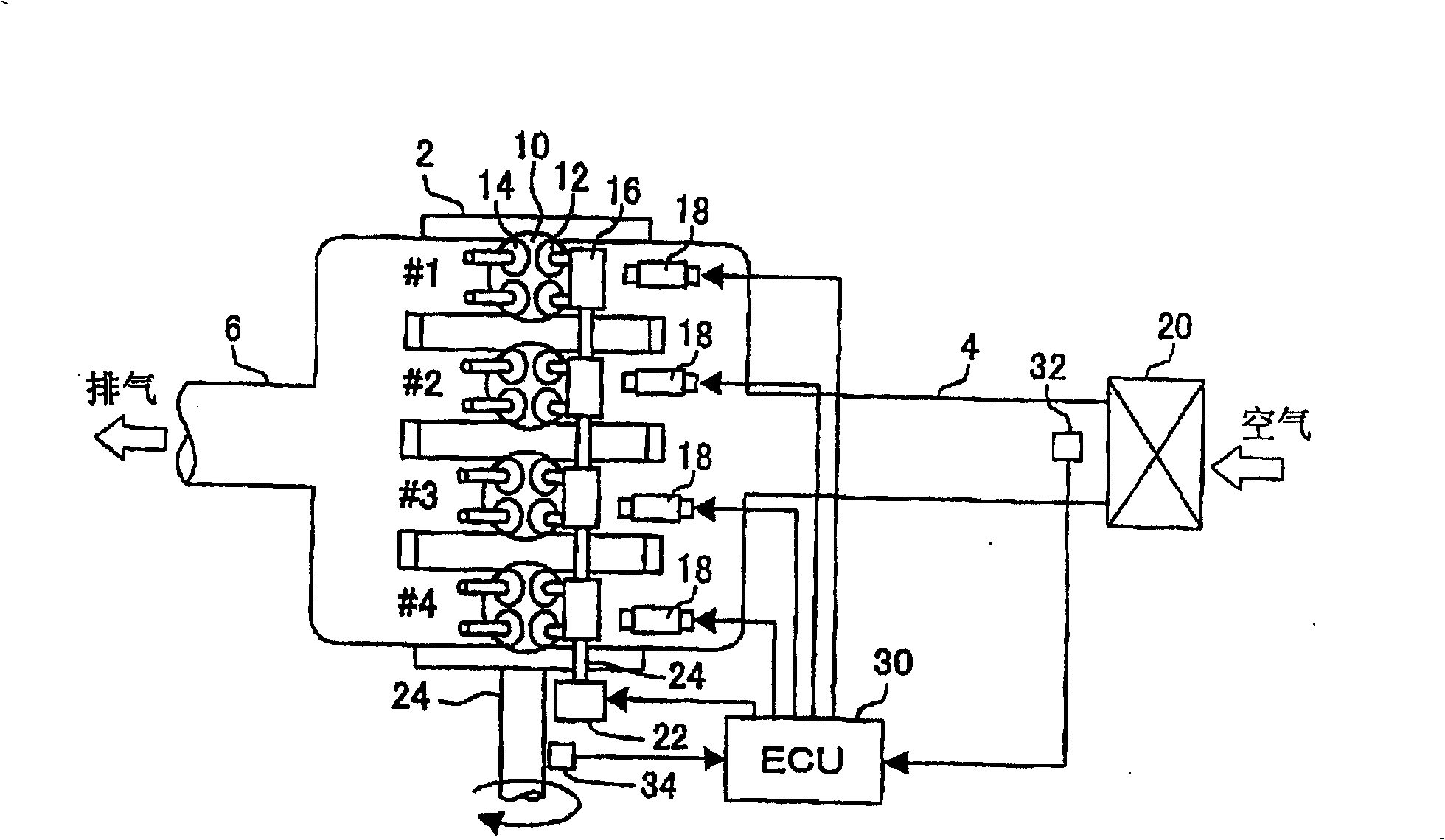

[0072] Below, refer to Figure 1 to Figure 6 Embodiment 1 of the present invention will be described.

[0073] figure 1 It is used to describe the structure of an internal combustion engine to which an intake air amount deviation detecting device according to an embodiment of the present invention is applied. The internal combustion engine 2 of the present embodiment is configured as an inline four-cylinder internal combustion engine having four cylinders #1 to #4.

[0074] The internal combustion engine 2 has an intake passage 4 through which air is introduced and an exhaust passage 6 through which combustion gas is discharged. An air cleaner 20 is provided at the upstream end of the intake passage 4 , and an air flow meter 32 for measuring the amount of intake air (inflow of air per unit time) is provided at a downstream portion close to the air cleaner 20 . The downstream side end portion of the intake passage 4 and the upstream side end portion of the exhaust passage 6 ...

Embodiment approach 2

[0096] Below, refer to Figure 7 Embodiment 2 of the present invention will be described.

[0097] As the intake air amount deviation detecting device according to the second embodiment of the present invention, in the first embodiment, the ECU 30 can execute Figure 7 program instead of Figure 5 program to achieve.

[0098] In Embodiment 1, although the variation in the amount of intake air generated among the cylinders is detected, it is not detected which cylinder has a large amount of intake air and which cylinder has a small amount of intake air. In order to individually adjust the operating angle and lift of the intake valve 12 of each cylinder, it is desirable to be able to grasp the amount of deviation of the intake air amount from the reference value for each cylinder. The deviation of the intake air amount for each cylinder can be detected by controlling the fuel injection amount for each cylinder according to the basic method described above. That is, when the ...

Embodiment approach 3

[0110] Below, refer to Figure 8 Embodiment 3 of the present invention will be described.

[0111] As the intake air amount deviation detecting device according to the third embodiment of the present invention, in the first embodiment, the ECU 30 can execute Figure 8 program instead of Figure 5 program to achieve.

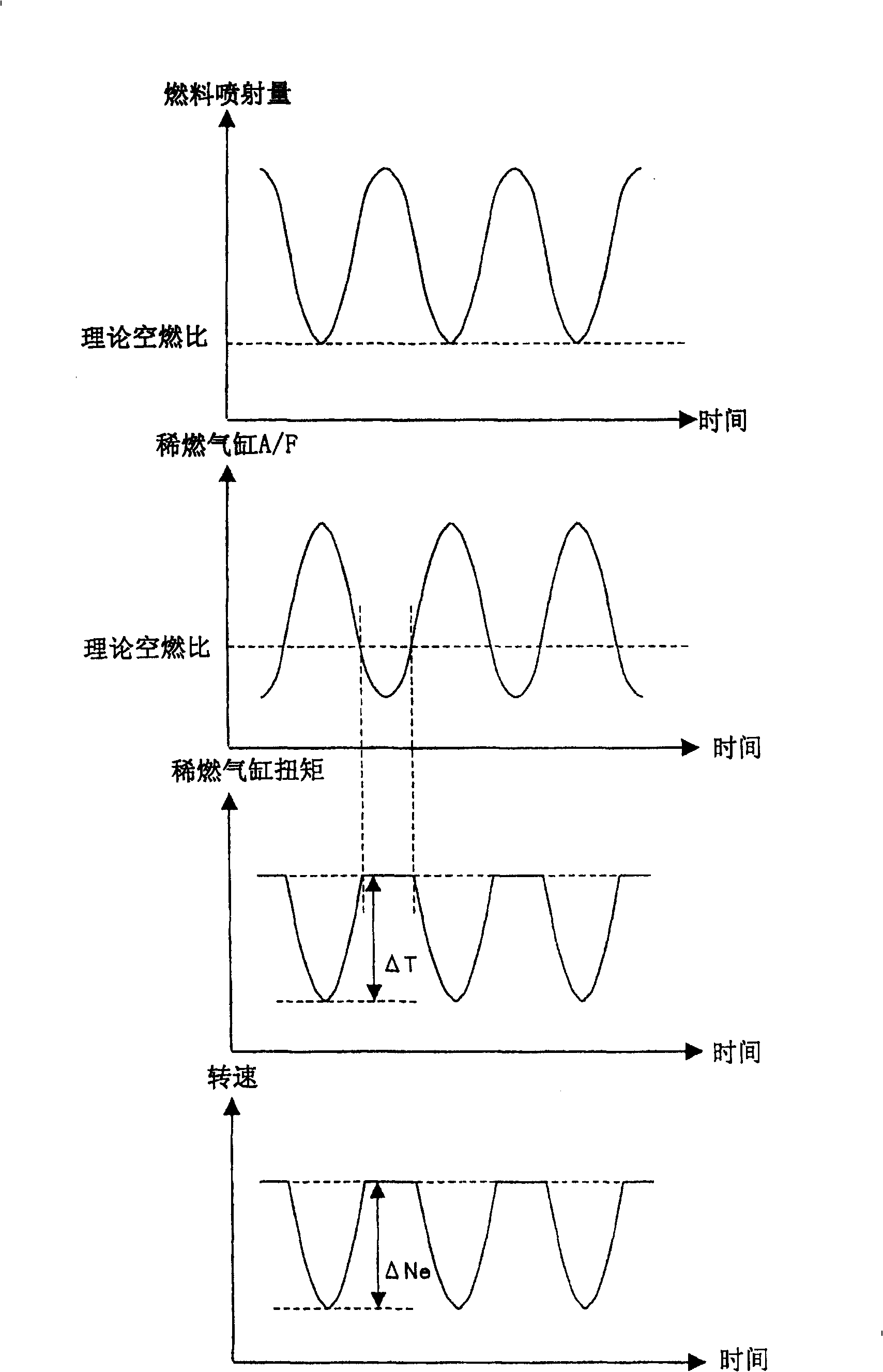

[0112] In Embodiment 2, by changing only the fuel injection amount of a specific cylinder among a plurality of cylinders, a deviation in the intake air amount of the cylinder is detected. However, combustion occurs sequentially in each cylinder, and the torque and rotation speed fluctuate under the influence of the combustion state of the cylinder currently in the combustion process. Therefore, even when the fuel injection amounts of all cylinders are changed uniformly as in the first embodiment, by monitoring the change in torque or rotational speed in the combustion stroke of each cylinder for each cylinder and measuring the vibration amplitude, it is possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com