Ultrasonic motor, and electronic timepiece having ultrasonic motor

An ultrasonic motor and ultrasonic technology, applied in electromechanical clocks, piezoelectric effect/electrostrictive or magnetostrictive motors, clocks, etc., can solve problems such as difficulties, increased sliding, and deterioration of oil quality, and achieve durability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

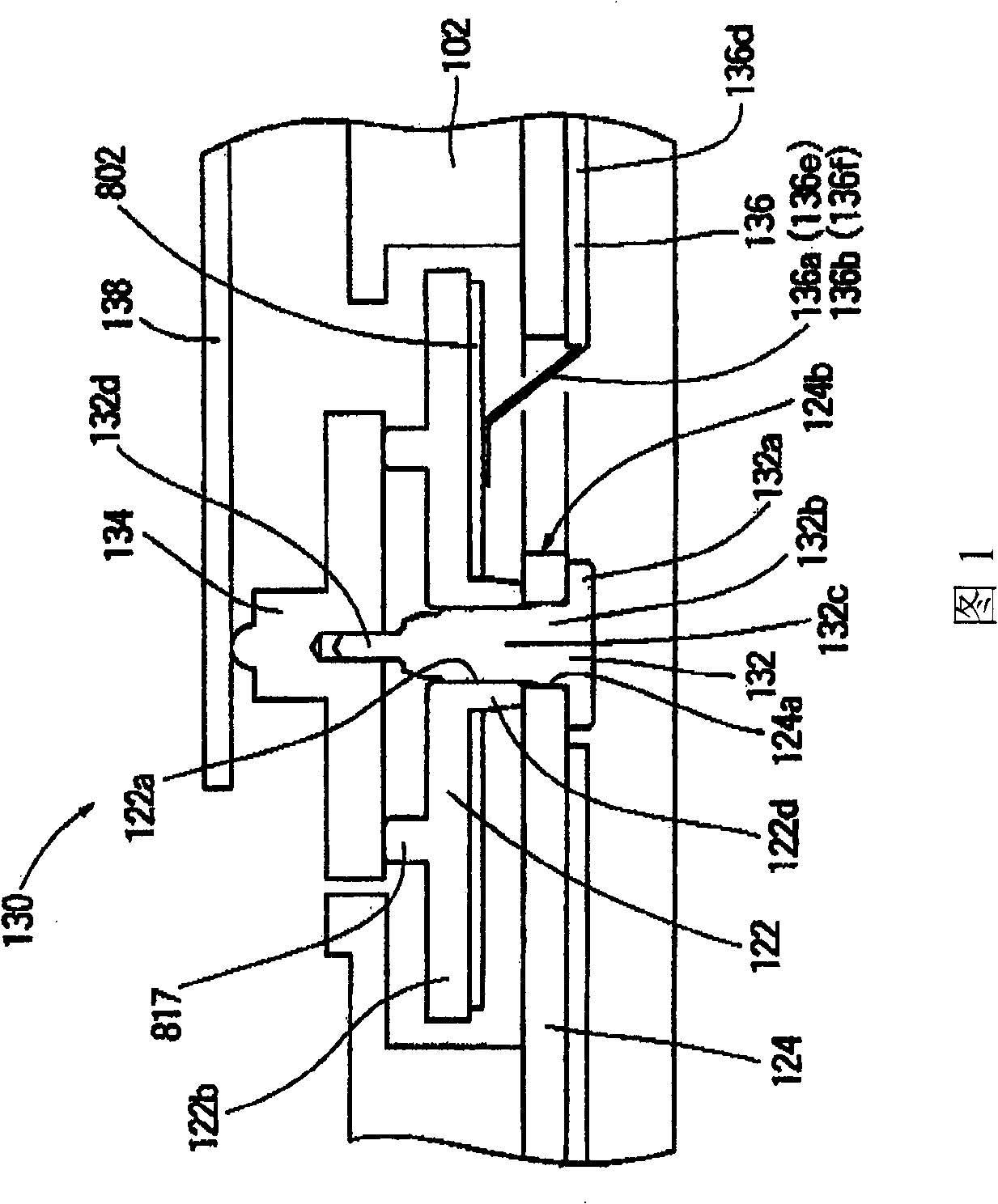

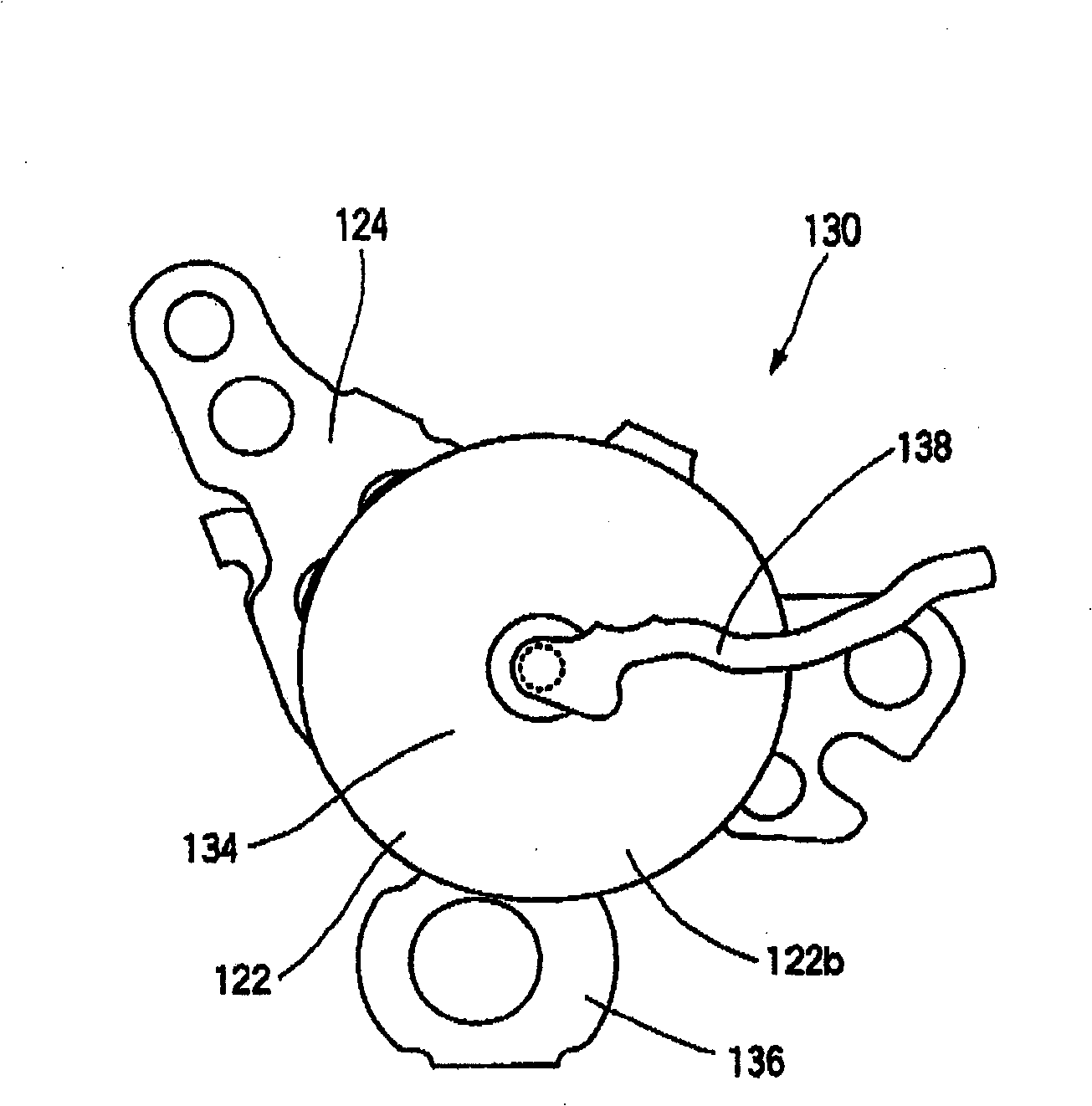

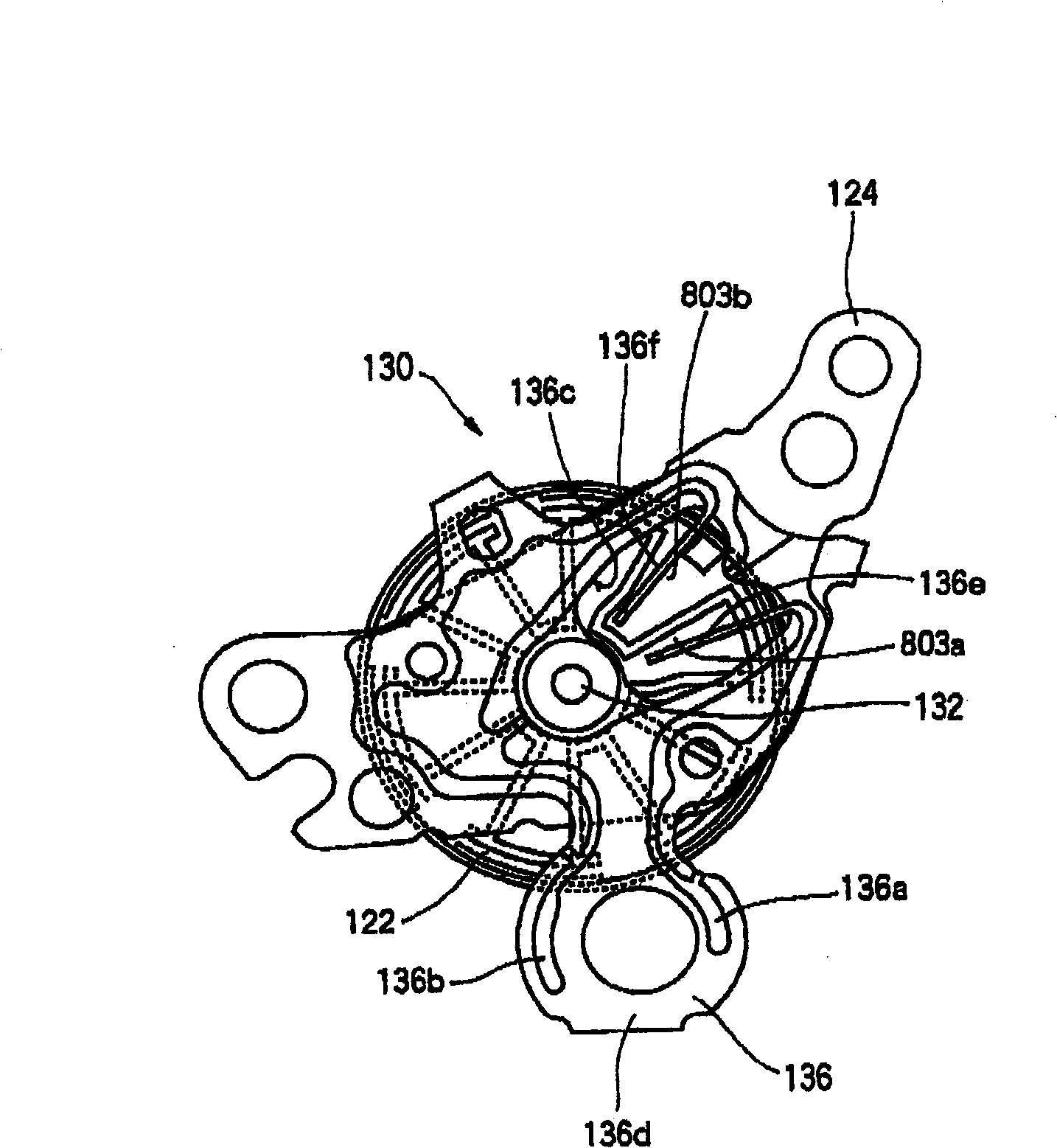

[0029] (1) [Structure of Ultrasonic Motor]

[0030] 1-3, the ultrasonic motor 130 of the present invention is provided with an ultrasonic stator 122, an ultrasonic motor support 124, an ultrasonic motor shaft 132, an ultrasonic rotor 134, and an ultrasonic motor guide substrate 136. The ultrasonic motor shaft 132 has a collar portion 132a, a first shaft portion 132b, a second shaft portion 132c, and a tip shaft portion 132d.

[0031] The ultrasonic motor support 124 has a first through hole 124a through which the ultrasonic motor shaft 132 passes, and a second through hole 124b through which the conduction structure of the ultrasonic motor guide substrate 136 passes. The ultrasonic motor support 124 is fixed to the first shaft portion 132b of the ultrasonic motor shaft 132 by passing the first through hole 124a through the ultrasonic motor shaft 132 . The lower surface of the ultrasonic motor support 124 is in contact with the collar portion 132 a of the ultrasonic motor shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com