Sealing device

A technology of sealing device and main seal, applied in the direction of engine seal, bearing, shaft, etc., can solve the problem of sealing characteristics without any elaboration, and achieve the effect of high friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

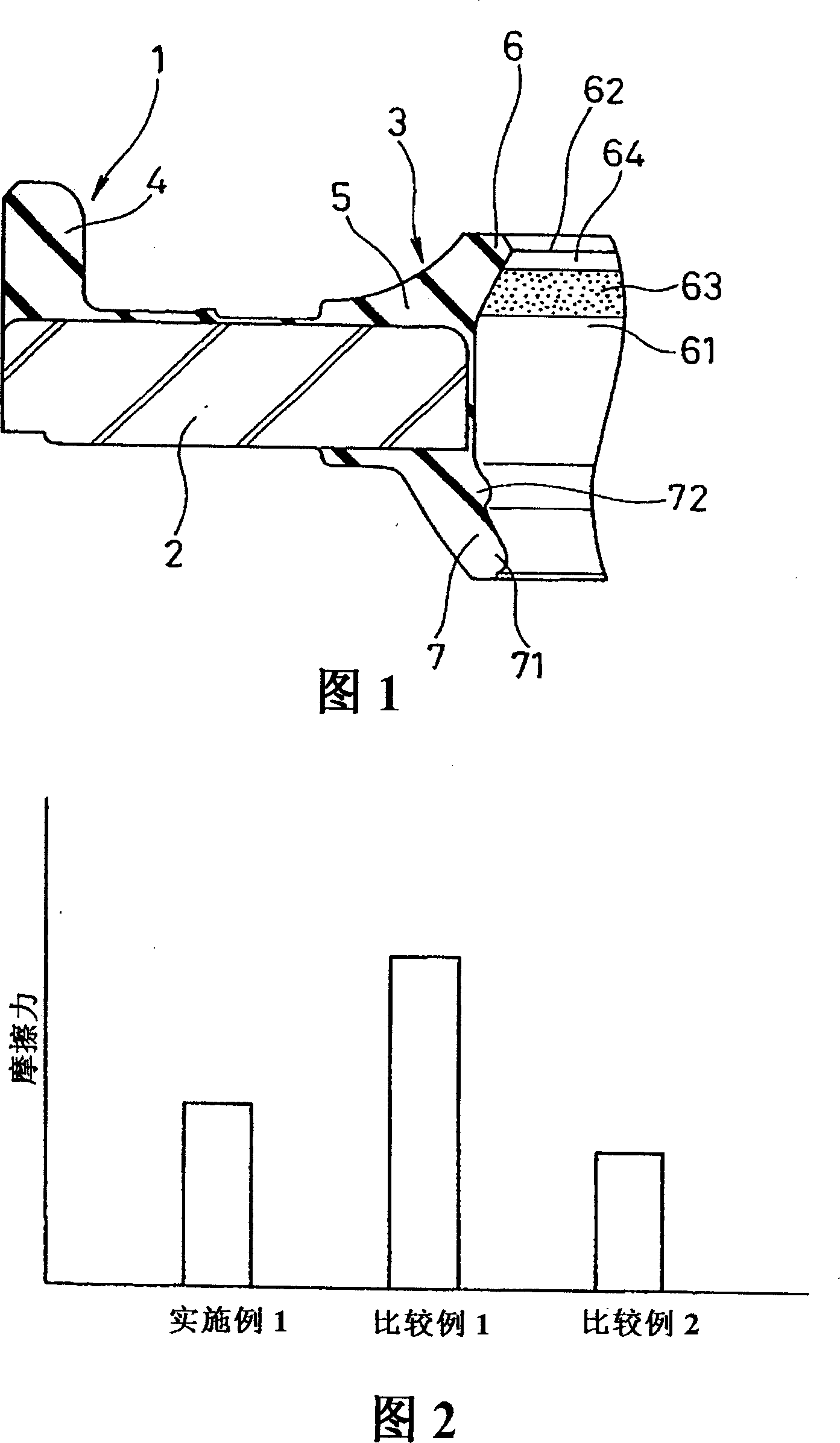

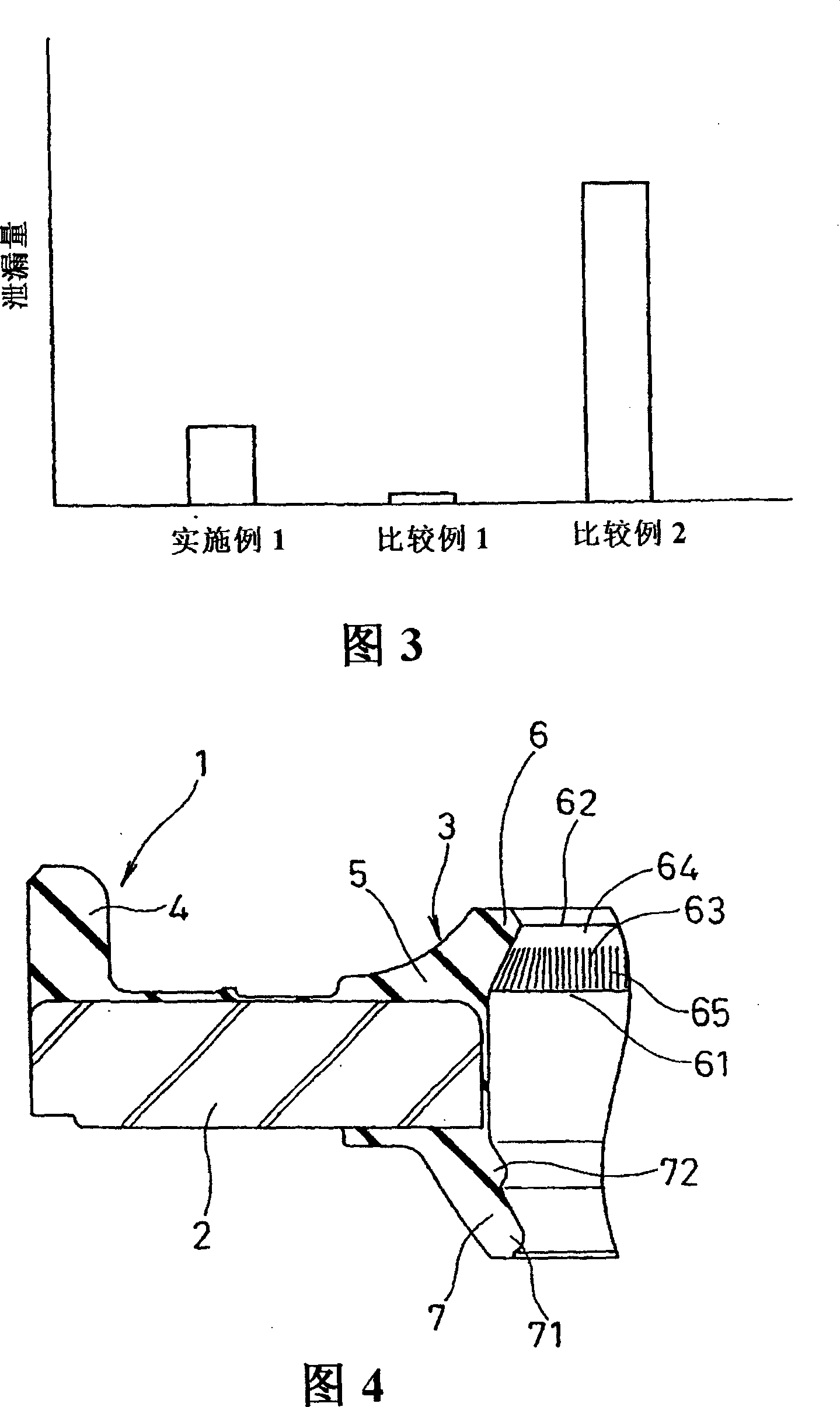

[0046] Fig. 1 shows a section of key parts of a sealing device 1 according to a first embodiment of the present invention, which has the following structure.

[0047] The sealing device 1 includes a metal ring 2 with a cross-sectional cylindrical shape, and a sealing body 3 that is vulcanized and bonded on the metal ring 2 and is composed of a rubber-like elastic body. The sealing body 3 integrally vulcanizes the fixed abutting part 4 and the sealing part 5 on the metal ring 2 . Among them, the fixed close part 4 is in close contact with the housing not shown in the figure located on the sealing object side (inner side) on the outer peripheral side of the metal ring 2; The shaft is snug and slidable. The seal part 5 is composed of a main seal lip 6 and a dustproof seal lip 7. The main seal lip 6 is located on the inner side of the metal ring 2 and extends toward the inner side. Structure, the dust-proof sealing lip 7 is located on the outer side of the metal ring 2 and exten...

no. 2 example

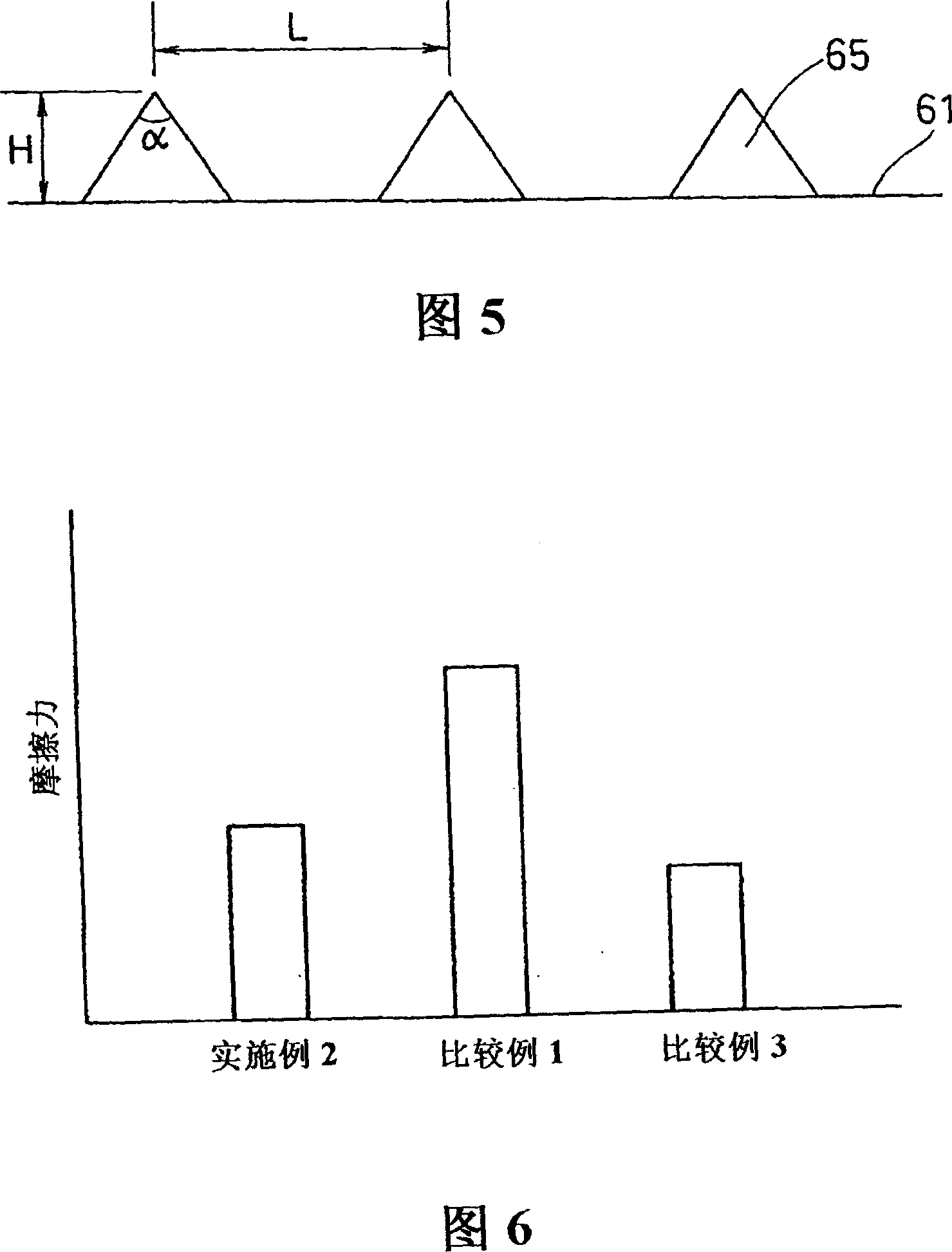

[0059] Fig. 4 shows the cross-section of key parts of the sealing device 1 according to the second embodiment of the present invention, and Fig. 5 is a cross-sectional view for explaining the projection shape image formed on the sliding surface of the main sealing lip in Fig. Different parts of the first embodiment.

[0060] In the second embodiment, on the sliding surface 61 of the main sealing lip 6 at a predetermined distance from the lip 62 , a plurality of protrusions 65 extending in the axial direction are arranged at equal intervals to cover the entire circumference. That is, the protrusion 65 parallel to the axial direction is provided on the rough-finished part 63 formed on the sliding surface 61 . Thus, between a set distance from the lip 62 to the protrusion 65 , a flat portion 64 is formed on which no concavo-convex portion is provided on the surface.

[0061] The protrusion 65 should be formed at a position 0.2 to 1 mm away from the lip 62 , preferably 0.3 to 0.7...

no. 3 example

[0071] Fig. 8 shows the section of key parts of the sealing device 1 according to the third embodiment of the present invention, and only the parts different from the first and second embodiments will be introduced below.

[0072] In the third embodiment, on the sliding surface 61 of the main sealing lip 6 at a position with a set distance from the lip 62, a plurality of arc-shaped notches 67 extending in the axial direction are arranged at equal intervals on the entire peripheral surface superior. That is, the rough-worked portion 63 formed on the sliding surface 61 is provided with a plurality of boat-shaped notches 67 parallel to the axial direction. Thus, between a set distance from the lip 62 to the boat-shaped notch 67, a flat portion 64 on which no concavo-convex portion is provided on the surface is formed.

[0073] In the case of configuring the sealing device 1 of the third embodiment having the above-mentioned structure, the sliding surface 61 of the main seal lip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com