Package box liner

A packaging box and lining technology, applied in the field of packaging box lining with a one-piece structure, can solve the problems of non-degradable, large wood consumption, unfavorable environmental protection, etc., and achieve the effect of firm structure, simple processing, and cushioning impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

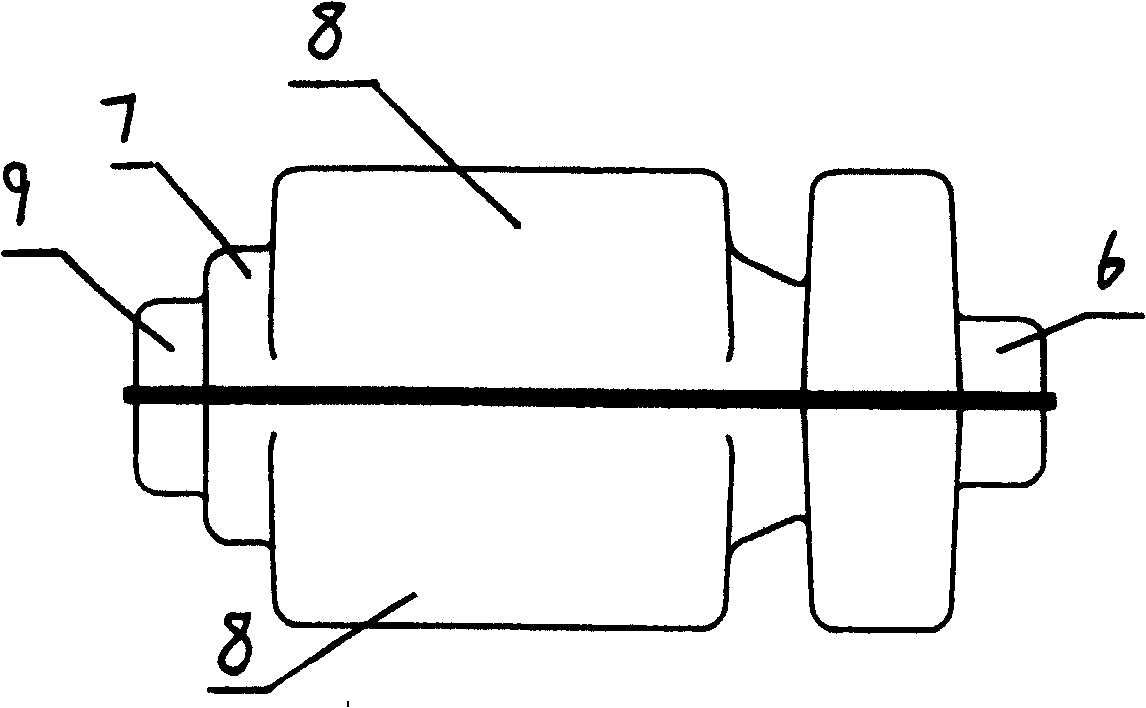

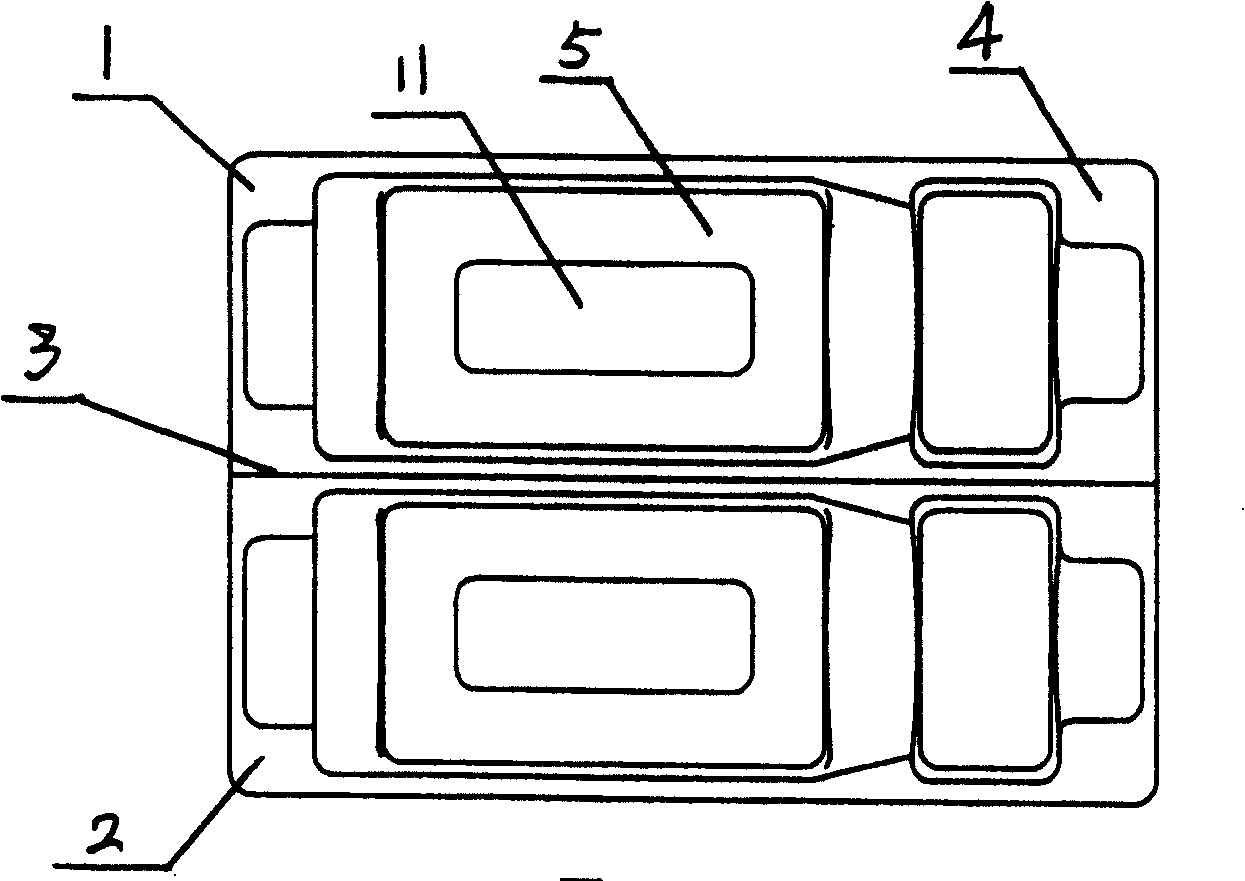

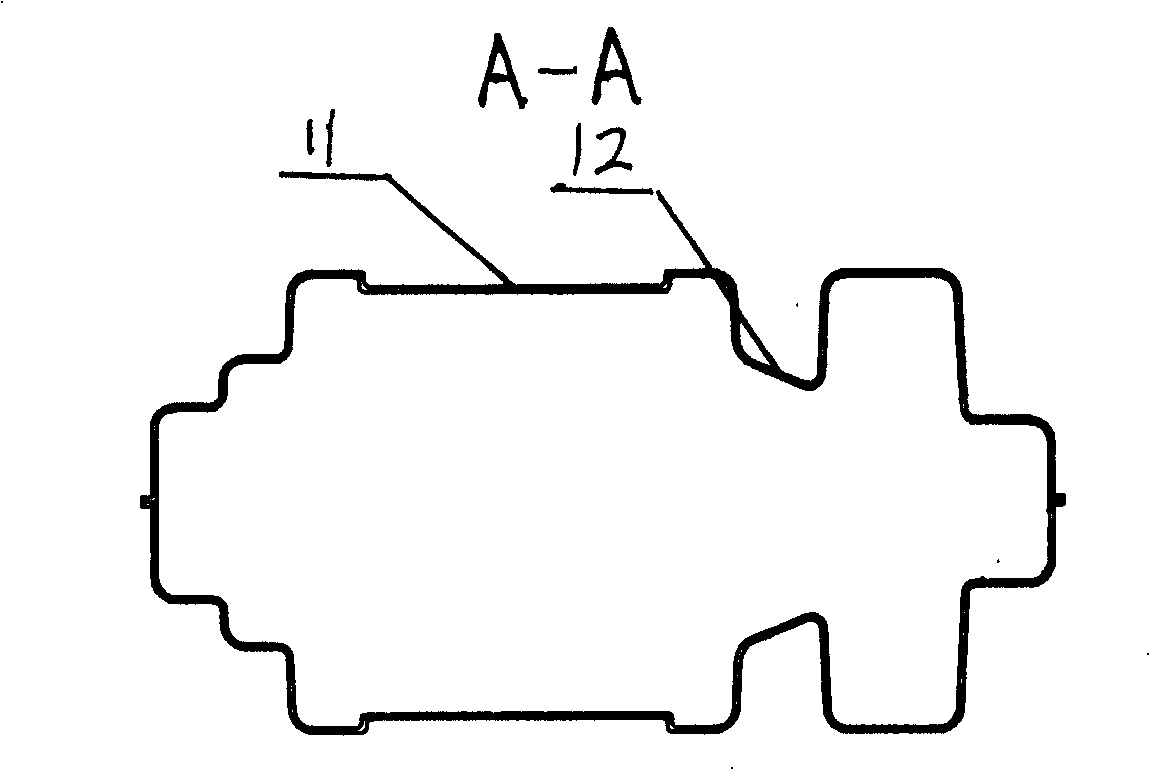

[0020] In the following, the container in the inner liner of the packaging box is the bottle body for description. like figure 1 , 2 , 3, and 4 show the inner lining of the packing box, including base 1 and cover 2, base 1 and cover 2 are a conjoined structure, a bending line 3 is set between base 1 and cover 2, base 1 and cover 2 Through the bending and fitting of the bending line 3, the base 1 is provided with a cavity 5 that matches the shape of the bottle body. This cavity 5 has a top support platform 6 and a bottom support platform 7 that match the shape of the contained bottle body. The mouth of the bottle and the bottom edge of the bottle are placed on the top support platform 6 and the bottom support platform 7, which support and limit the bottle body, so that the bottle body placed in the inner liner of the packaging box will not slide during the movement process. .

[0021] At least one buffer pit 8 can be set between the top support platform 6 and the bottom supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com