Machine component using ic tag and its method for quality control and system for inspecting abnormality

A technology for mechanical parts and quality management, applied in computer parts, mechanical equipment, record carriers used by machines, etc., can solve the problems of impossible to know abnormality, inability to measure abnormality, impossible to know exactly the state of bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Hereinafter, preferred embodiments of the present invention will be described while referring to the accompanying drawings.

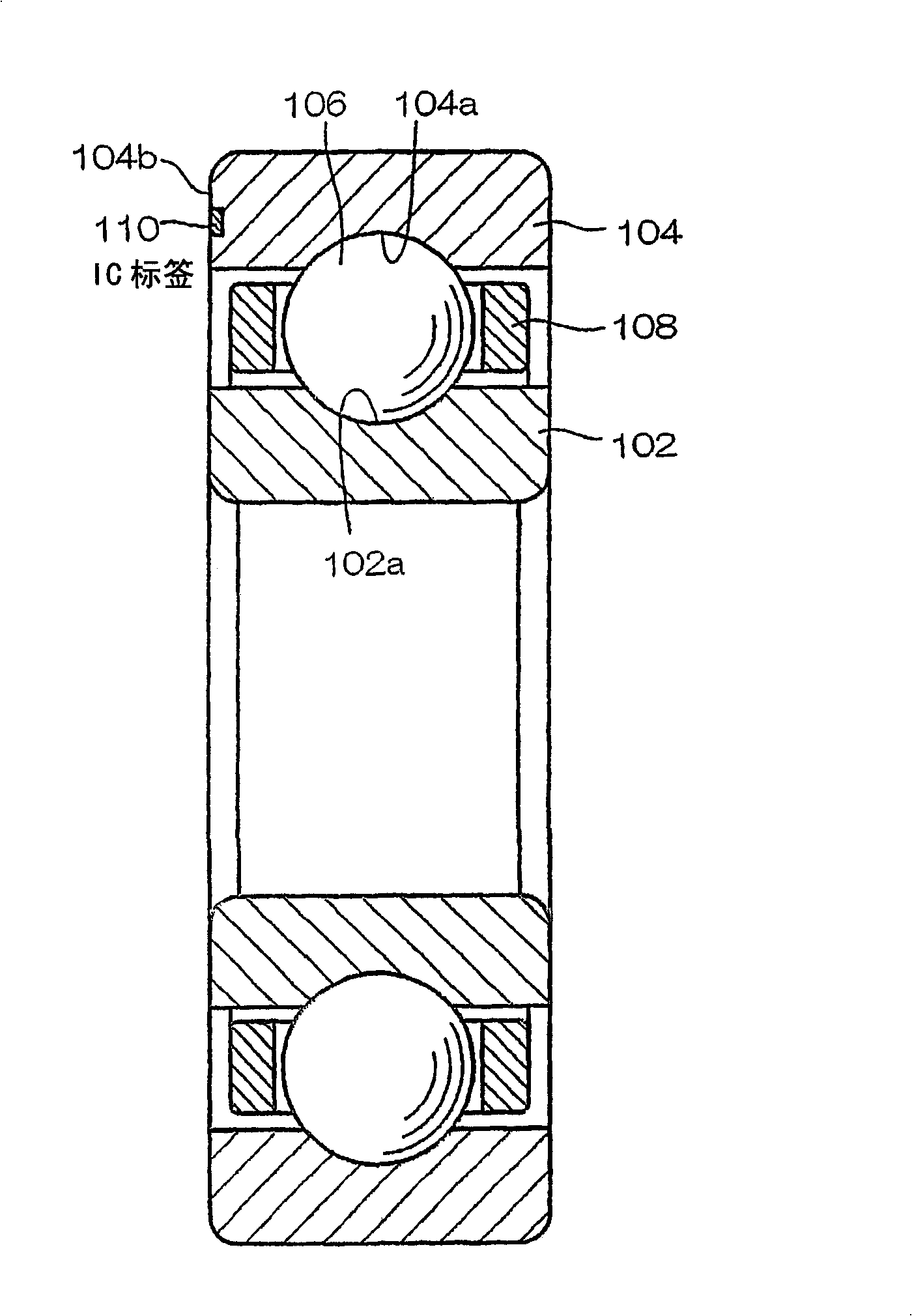

[0125] figure 1 A first embodiment of the present invention is shown, that is, a cross-sectional view of a deep groove ball bearing as an example of a mechanical part. This bearing has an inner ring 102 , an outer ring 104 , a plurality of balls (rolling elements) 106 , and a cage 108 as main constituent units. The inner ring 102 has a raceway 102a on the outer peripheral surface. The outer ring 104 has a raceway 104a on the inner peripheral surface. Balls 106 can freely roll between the raceway 102a of the inner ring 102 and the raceway 104a of the outer ring 104 . The balls 106 are held at predetermined intervals in the circumferential direction by the cage 108 . In this embodiment, the IC tag 110 is embedded in the end surface 104b of the outer ring 104 .

[0126] It is desirable that the IC tag 110 is a built-in part where no load is ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com